Reference Notes

3-6

TCPA300/400 Amplifiers and TCP300/400 Series Current Probes Instruction Manual

Measuring Noncontinuous Current with the TCP404XL Probe

When you measure a noncontinuous current with the TCP 404XL probe, you

need to take into consideration several factors to ensure that you make accurate

measurements and do not trip the thermal overload circuit. The amplitude and

duty cycle of the continuous and noncontinuous current, and the ambient

temperature, all affect the maximum amount of time allowed for the measure-

ment, which defines the safe operating area of the probe.

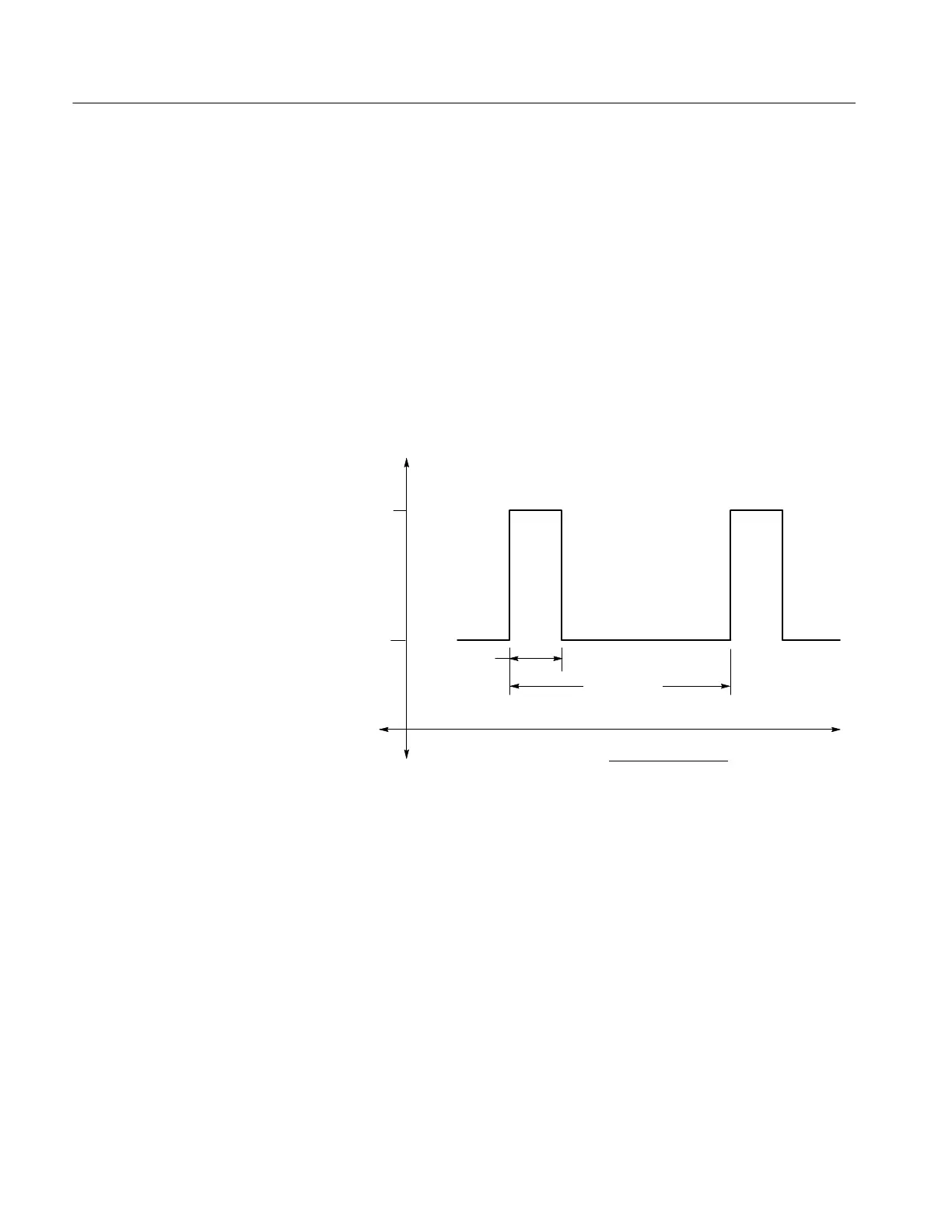

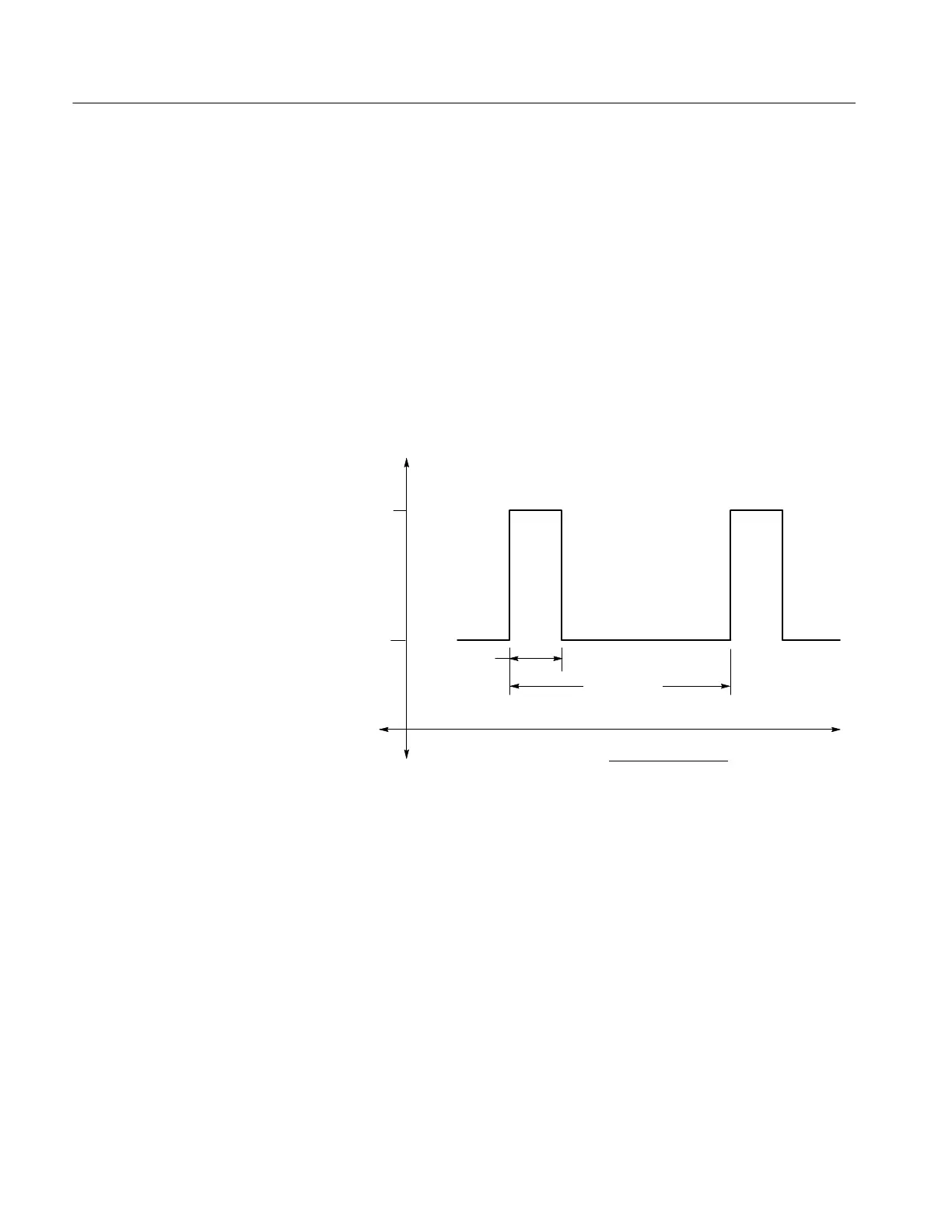

You can calculate the duty cycle of the continuous and noncontinuous current

when you know the duration of the noncontinuous current (defined in F igure 3--4

as measurement time) and the measurement period. F igure 3--4 illustrates a

continuous and noncontinuous current and how to calculate the duty cycle.

Measured

current (A)

Noncontinuous

current level (A)

Continuous

current level (A)

Measurement

time (min)

Measurement

period (min)

Time (min)

Duty cycle (%) = 100x

Measurement time

Measurement period

Figure 3- 4: Duty cycle calculation

After you calculate the duty cycle of the noncontinuous current you are

measuring, you can use the other factors (continuous and noncontinuous current

amplitude, etc.) to compare your measurement to those s hown in Figures 4--8

through 4--10 in the Specifications section.

You can see how duty cycle affects the measurement time by looking at any of

the three graphs in Figures 4-- 8 through 4--10. As the duty cycle increases on the

x-axis, the measurement time (of the noncontinuous current) on the y-axis

decreases.

Figures 4--8 and 4--9 on page 4--12 illustrate the effect of measuring two different

noncontinuous current amplitudes, 750 amps and 600 amps respectively, with

Loading...

Loading...