TDS 340A, TDS 360 & TDS 380 Technical Reference

5–1

Adjustment Procedures

This chapter contains information you need to adjust the TDS 340A, TDS 360,

and TDS 380. There are only three types of adjustments you can perform on the

oscilloscope: the automated and semiautomated adjustments in the system

calibration menu, attenuator adjustments, and monitor adjustments.

You should do the signal path compensation adjustment after servicing your

instrument or moving your instrument to a new operating environment (±5_ C

temperature change). The other adjustment procedures may be necessary if the

instrument fails one of the Performance Tests in the previous section.

Let the instrument warm up for 20 minutes before performing any adjustments.

Adjustment Interval. These adjustments should be done once a year.

Equipment Required

Table 5–1 lists the equipment you will need to do the adjustment procedures.

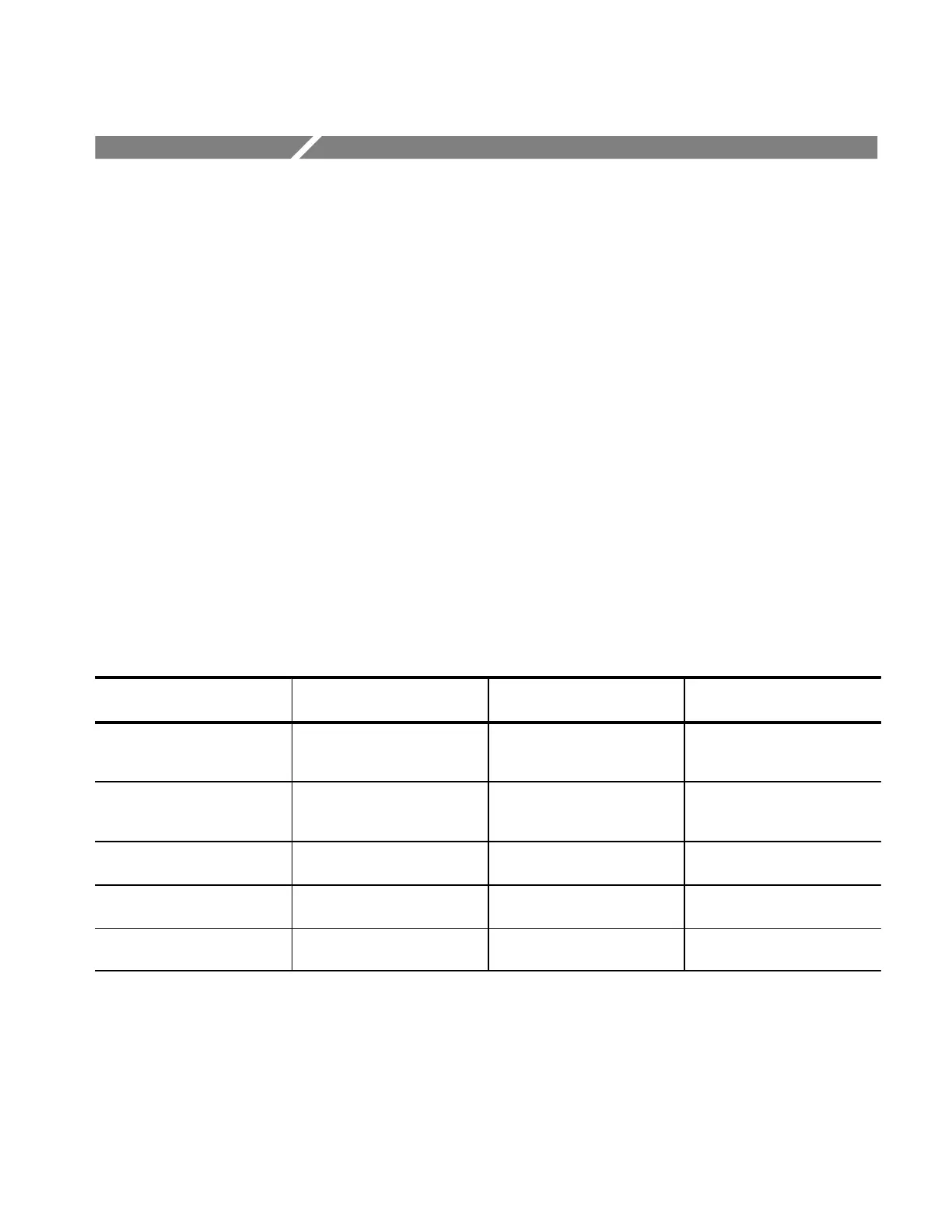

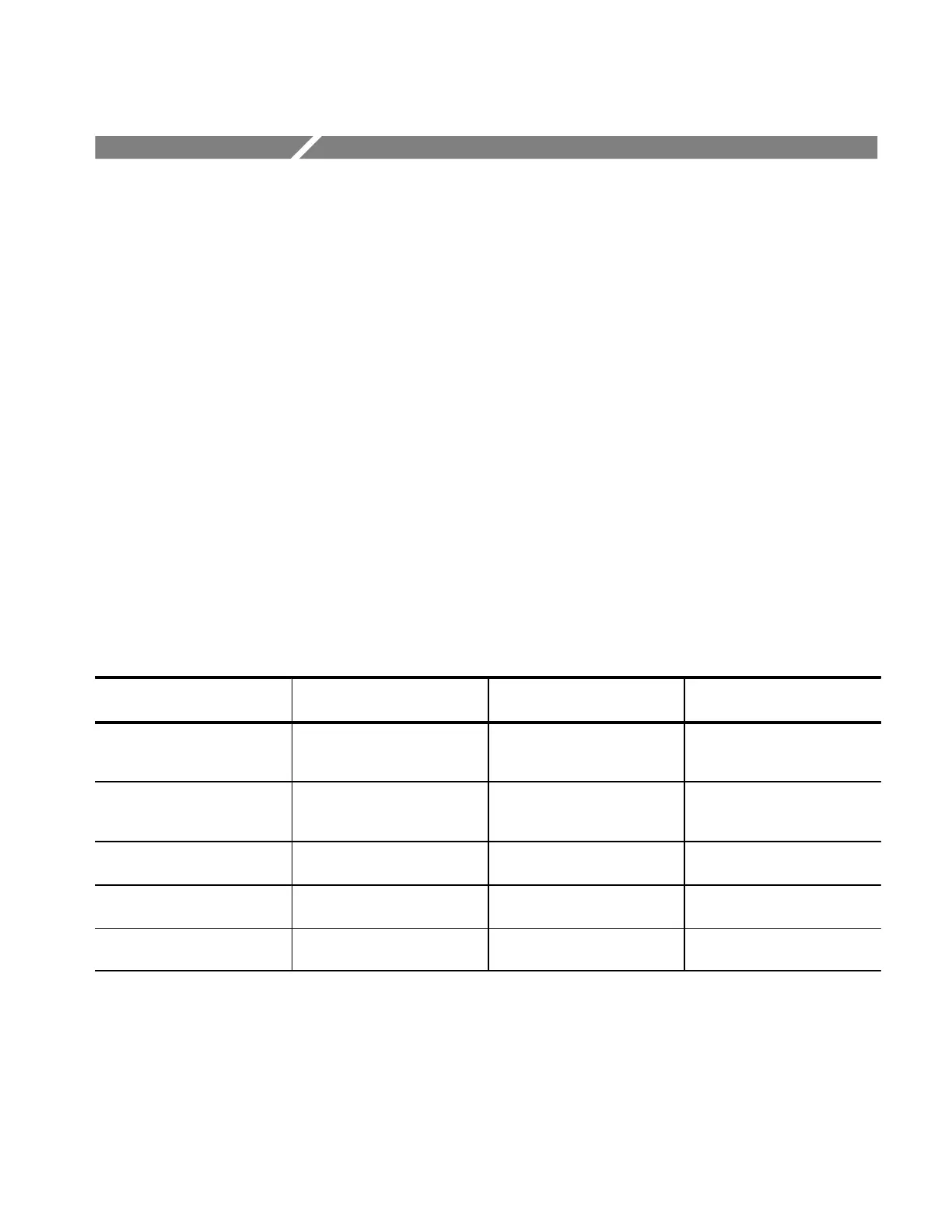

Table 5–1: Adjustment equipment

Item number

and description

Minimum requirements Example Purpose

1. Adjustment Tool 0.075 inch slot screwdriver Tektronix part number

003-1433-01 (standard probe

adjustment tool)

Monitor and attenuator adjust-

ments

2. Termination, 50 W Impedance 50 W; connectors:

female BNC input, male BNC

output

Tektronix part number

011-0049-01

Timing calibration and attenua-

tor adjustment

3. Cable, Precision Coaxial 50 W , 36 in, male to male BNC

connectors

Tektronix part number

012-0482-00

Attenuator adjustments and

system calibration

4. Generator,

DC Calibration

Variable amplitude to ±10 V;

accuracy to 0.05%

Wavetek 9100 Calibration

System with Option 250

Voltage and external trigger

calibrations

5. Generator,

Fast-rise Step

t

r

≤ 10 ns;

amplitude ≤ 1 V

p-p

Wavetek 9100 Calibration

System with Option 250

Timing calibration and attenua-

tor adjustment

Loading...

Loading...