~-------

~

945424-9701

2.6.1

POWER/LOGIC

PWB

PRELIMINARY

CHECKOUT.

Upon receipt

of

a suspect power/

logic pwb from the field maintenance facility, visually inspect the board for the problems listed

in paragraph 2.4.1.

If

a thorough visual inspection indicates no problems, proceed with the fault

isolation procedure for the pwb.

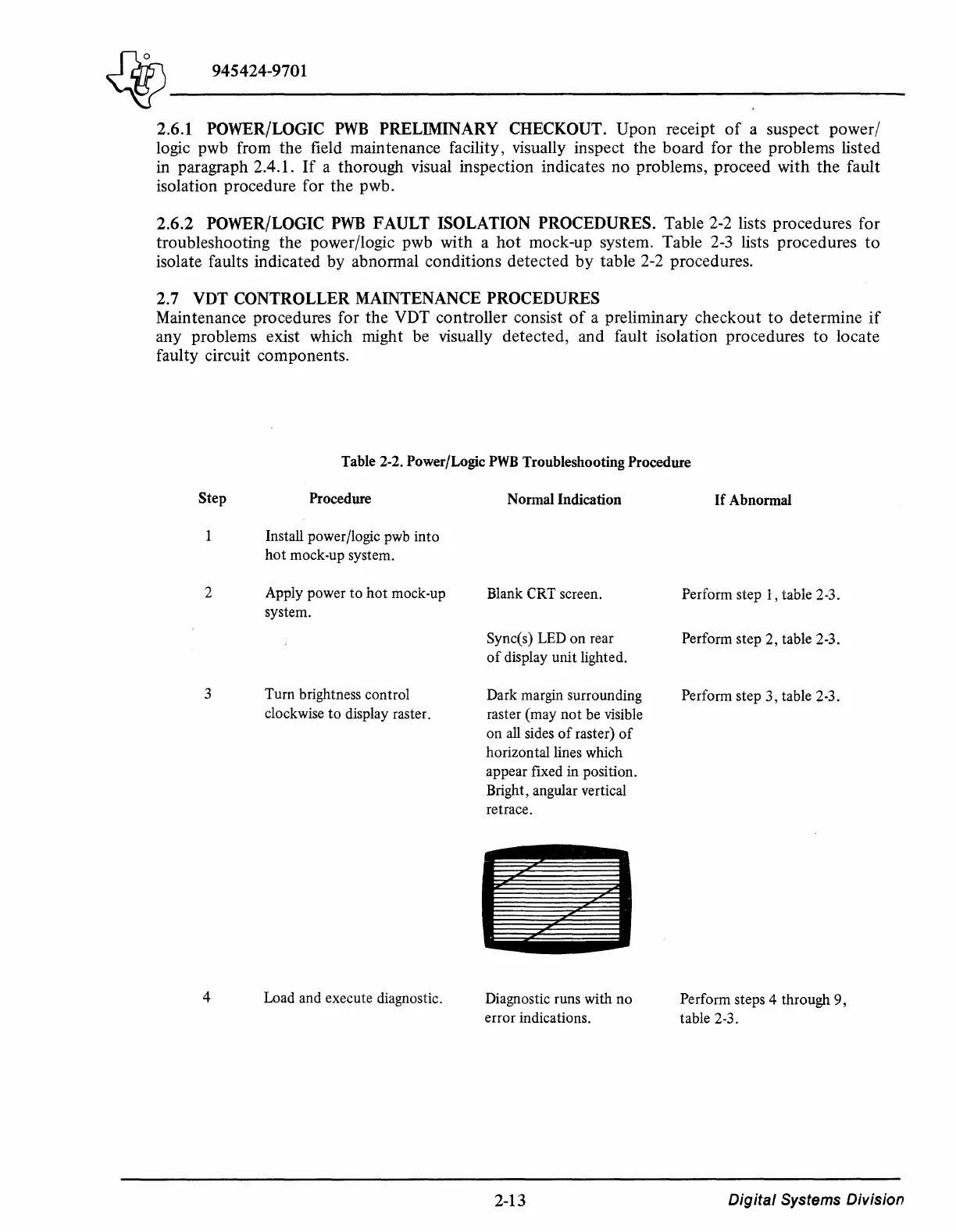

2.6.2

POWER/LOGIC

PWB

FAULT

ISOLATION

PROCEDURES.

Table

2-2

lists procedures for

troubleshooting the power/logic pwb with a

hot

mock-up system. Table

2-3

lists procedures

to

isolate faults indicated by abnormal conditions detected by table

2-2

procedures.

2.7

VDT

CONTROLLER

MAINTENANCE

PROCEDURES

Maintenance procedures for the VDT controller consist

of

a preliminary checkout

to

determine

if

any problems exist which might be visually detected, and fault isolation procedures to locate

faulty circuit components.

Step

2

3

4

Table

2-2.

Power/Logic

PWB

Troubleshooting

Procedure

Procedure

Install power/logic pwb

into

hot

mock-up system.

Apply power

to

hot

mock-up

system.

Turn brightness control

clockwise

to

display raster.

Load and execute diagnostic.

Normal

Indication

Blank CRT screen.

Sync(s) LED

on

rear

of

display

unit

lighted.

Dark margin surrounding

raster (may

not

be visible

on all sides

of

raster)

of

horizontal lines which

appear fixed in position.

Bright, angular vertical

retrace.

Diagnostic runs with

no

error indications.

2-13

If

Abnormal

Perform step 1, table 2-3.

Perform step

2,

table 2-3.

Perform step

3,

table 2-3.

Perform steps 4 through

9,

table 2-3.

Digital

Systems

Division

Loading...

Loading...