B02134

WIRING DIAGRAM

D Wiring Diagram

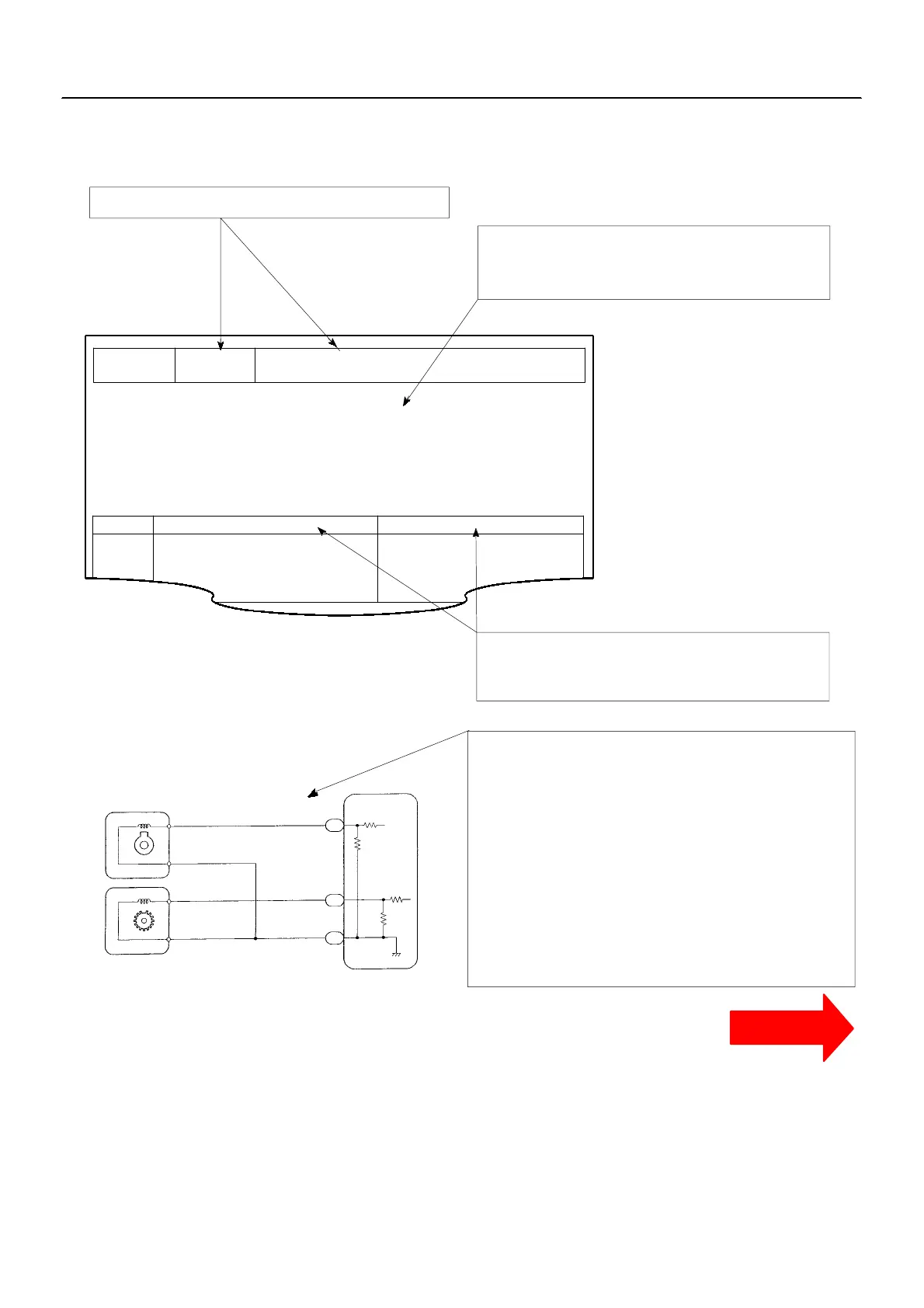

DTC 12

CIRCUIT DESCRIPTION

The crankshaft positi on sensor in the Engine Control System contains signal plate and a pickup coil for TDC signal.

The TDC s ignal plate has 1 tooth on its outer circumference. The TDC signal sensor generates 1 signal for every engine

revolution. The engi ne ECU detects the top dead center by the TDC signals. The NE signal plate has 52 teeth and is

mounted in the supply pump. The NE signal sens or generates 52 signal s of engine 2 revolutions. The engine ECU detects

the engine speed and cam lift position of the s upply pump. The engine E CU uses TDC signal and NE signals for injection

control. And NE signal i s used for injecti on volume control, also.

DTC No. DTC Detecting Condition Trouble Area

12

No TDC signal to engine ECU at 500 rpm or more

D Open or short in crankshaft position sensor

circuit

D Crankshaft position sensor

D Engine ECU

D Diagnostic Trouble Code No. and Detection Item

D Circuit Description

The major role and operation, etc. of the circuit

and its component parts are explained.

D Indicates the diagnostic trouble code, diagnostic

trouble code set parameter and suspect area of

the problem.

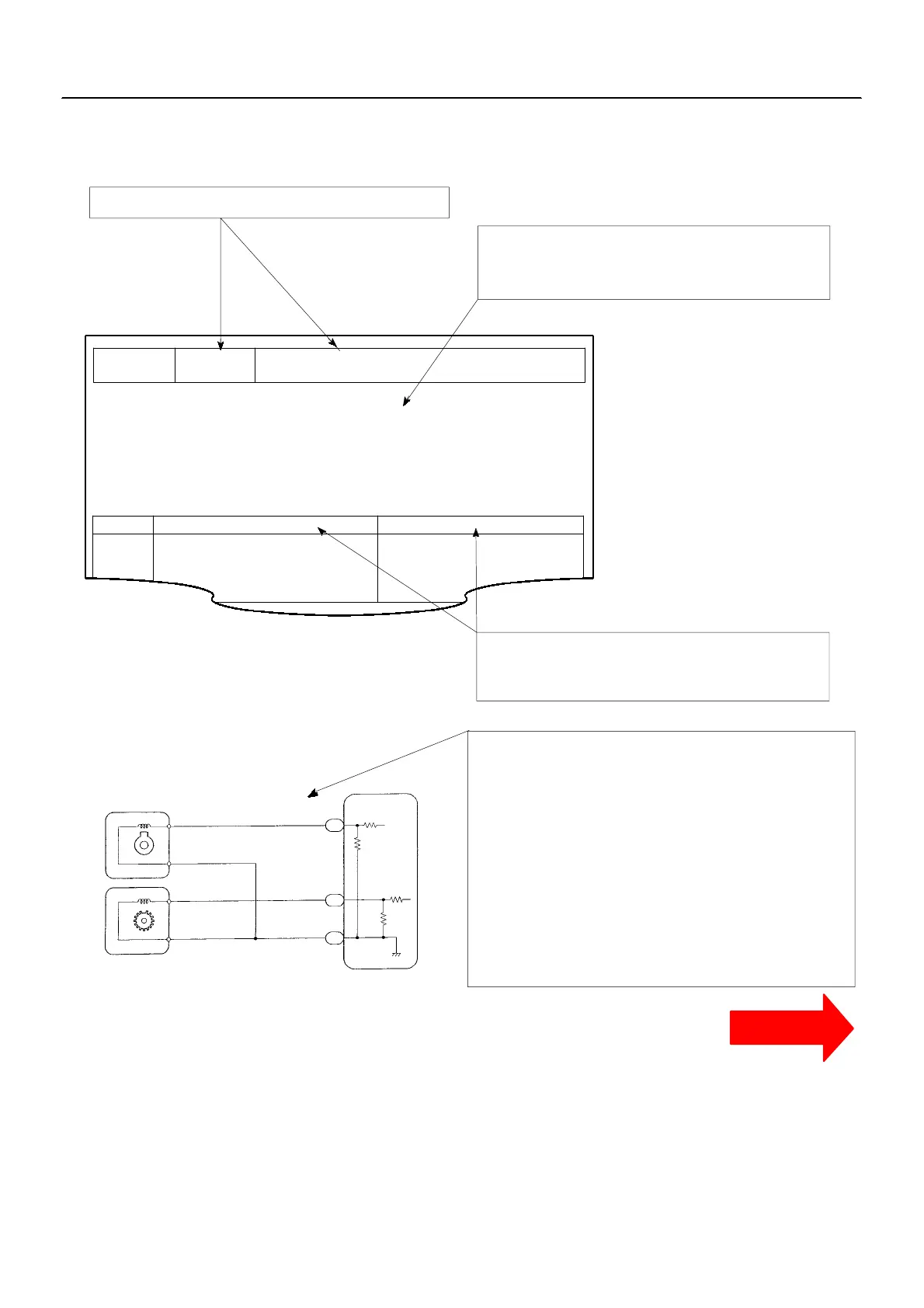

Crankshaft Position Sensor

1

2

1

2

Engine Speed Sensor

(inside the Suppy Pump)

B--W

L

B--R

B--R

BR L

E7

E7

E7

5

6

6

Engine ECU

G22+

NE+

NE--

E2

This shows a wiring diagram of the circuit.

Use this diagram t oget her wit h E LECT RI CA L

WIRING DIAGRAM to thoroughly understand the

circuit.

Wire colors are indicated by an alphabetical code.

B = Black, L = Blue, R = Red, BR = Brown,

LG = Light Green, V = Violet, G = Green,

O = Orange, W = White, GR = Gray, P = Pink,

Y = Yellow

The first letter indicates the basic wire color and the

second letter indicates the color of the stripe.

Crankshaft Position Sensor Circuit Malfunc-

tion

IN --18

--INTRODUCTION HOW TO TROUBLESHOOT ECU CONTROLLED

SYSTEMS

6 . CI RCUI T I NSPECTION

How to read and use each page is shown below.

CLICK HERE TO VIEW CHAPTER INDEX

Pages From Manual

CONTINUED

TO MODEL INDEX

1KZ-TE

Loading...

Loading...