1 - 10 RTHC-IOM-1C

NOTE: Field piping must be arranged and supported

to avoid stress on the equipment. It is strongly

recommended that the piping contractor provide at

least 3 feet (914 mm) of clearance between the pre-

installation piping and the planned location of the

unit. This will allow for proper fit-up upon arrival of the

unit at the installation site. All necessary piping

adjustments can be made at that time. Refer to the

current engineering bulletin for further details on

installation.

q Where specified, supply and install valves in the

water piping upstream and downstream of the

evaporator and condenser water boxes, to isolate

the shells for maintenance and to balance/trim the

system.

q Supply and install condenser water control

valve(s) per

Trane RLC-EB-4.

q Supply and install flow switches or equivalent

devices in both the chilled water and condenser

water piping. Interlock each switch with the proper

pump starter and UCP2, to ensure that the unit

can only operate when water flow is established

(ref. Section 3).

q Supply and install taps for thermometers and

pressure gauges in the water piping, adjacent to

the inlet and outlet connections of both the

evaporator and the condenser.

q Supply and install drain valves on each water box.

q Supply and install vent cocks on each water box.

q Where specified, supply and install strainers

ahead of all pumps and automatic modulating

valves.

q Supply and install refrigerant pressure relief

piping from the pressure relief to the atmosphere.

q If necessary, supply enough HCFC-134

refrigerant and dry nitrogen (75 psig) for pressure

testing.

q Start the unit under supervision of a qualified

service technician.

q Where specified, supply and insulate the

evaporator and any other portion of the unit, as

required, to prevent sweating under normal

operating conditions.

q For unit-mounted starters, cutouts are provided at

the top of the panel for line-side wiring.

q Supply and install the wire terminal lugs to the

starter.

q Supply and install field wiring to the line-side lugs

of the starter.

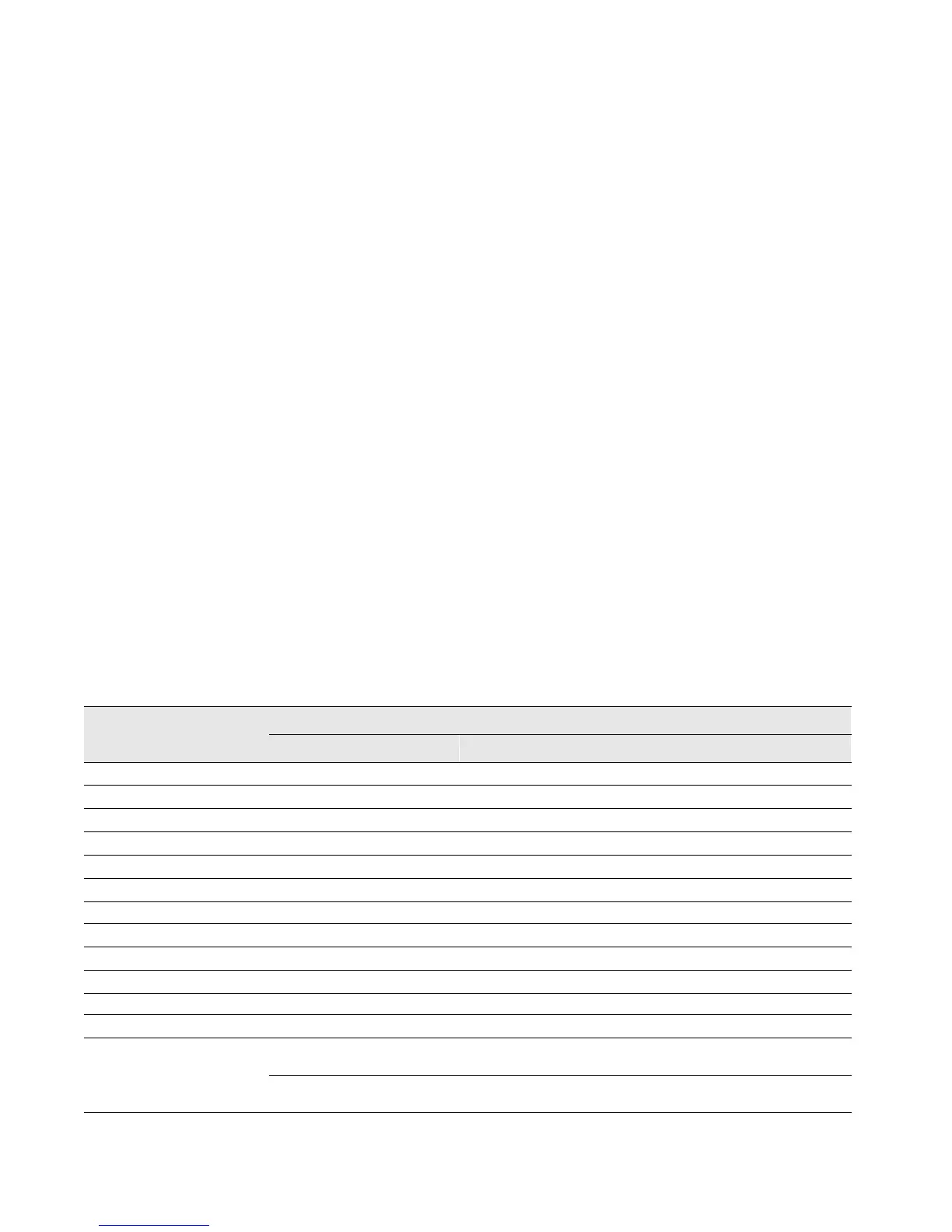

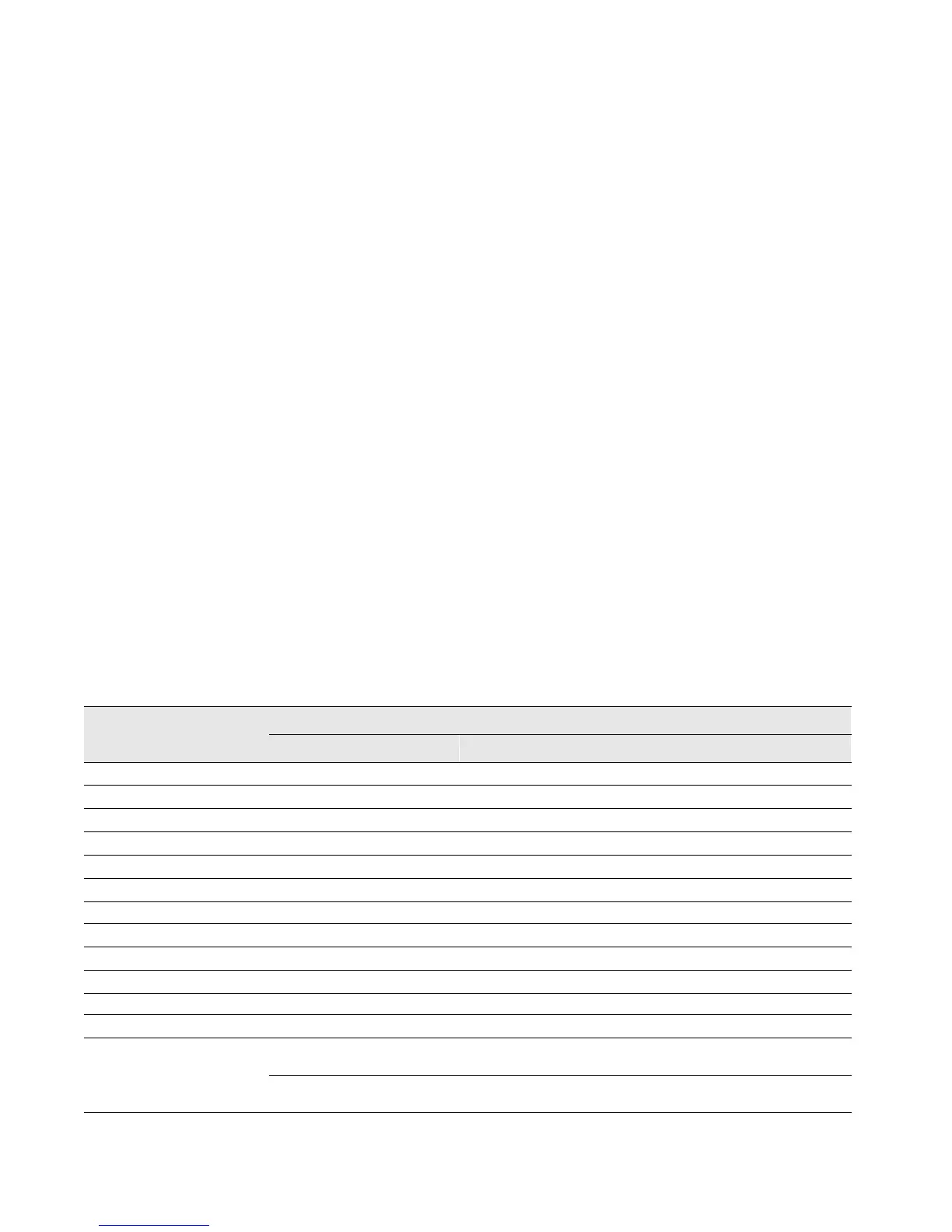

Table 5

General Data

Unit Designator

(corresponds to digits 6, 7, 12, 13, 16, 17 of unit model number)

D1D1E1 D1F1F2 D1G2G2 D2D2E2 D2F2F3 D2G3G3

General

Refrigerant Type

HFC-134a HFC-134a HFC-134a HFC-134a HFC-134a HFC-134a

Refrigerant Charge (lb (kg))

575 (261) 740 (336) 850 (385) 575 (261) 740 (336) 850 (385)

Oil Charge (gal (l))

6 (23) 10 (35) 11 (39) 6 (23) 10 (35) 11 (39)

Operating Weight (lb (kg))

15,850 (7189) 17,900 (8119) 21,400 (9707) 15,900 (7212) 18,700 (8482) 22,100 (10,024)

Shipping Weight (lb (kg))

15,000 (6804) 16,700 (7575) 19,600 (8890) 15,000 (6804) 17,400 (7892) 20,100 (9117)

Overall Dimensions

Length (in (mm))*

134 (3404) 149 (3785) 153 (3886) 134 (3404) 149 (3785) 153 (3886)

Width (in (mm))*

68 (1727) 69 (1753) 70 (1778) 68 (1727) 69 (1753) 70 (1778)

Height (in (mm))*

76 (1930) 76 (1930) 80 (2032) 76 (1930) 76 (1930) 80 (2032)

Evaporator

Water Storage (gal (l))

69 (261) 102 (386) 144 (545) 74 (280) 107 (405) 159 (602)

Minimum Flow (gpm (l/s))

454 (29) for

2-pass

626 (39) for

2-pass

606 (38) for

3-pass

498 (31) for

2-pass

669 (42) for

2-pass

690 (43) for

3-pass

303 (19) for

3-pass

417 (26) for

3-pass

454 (29) for

4-pass

332 (21) for

3-pass

446 (28) for

3-pass

518 (33) for

4-pass

Loading...

Loading...