2 - 26 RTHC-IOM-1C

NOTE: The UCP2 provides a 6-second time delay on

the flow switch input before shutting down the unit on

a loss-of-flow diagnostic. Contact a qualified service

organization if nuisance machine shutdowns persist.

q Adjust the switch to open when water flow falls

below nominal. Refer to the General Data table in

Section 1 for minimum flow recommendations for

specific water pass arrangements. Flow switch

contacts are closed on proof of water flow.

Refrigerant Pressure Relief Valve Venting

To prevent injury due to inhalation

of HFC-134 gas, do not discharge

refrigerant anywhere. If multiple

chillers are installed, each unit

must have separate venting for its

relief valves. Consult local regula-

tions for any special relief line

requirements.

NOTE: Vent pipe size must conform to the ANSI/

ASHRAE Standard 15 for vent pipe sizing. All

federal, state, and local codes take precedence over

any suggestions stated in this manual.

All relief valve venting is the responsibility of the

installing contractor.

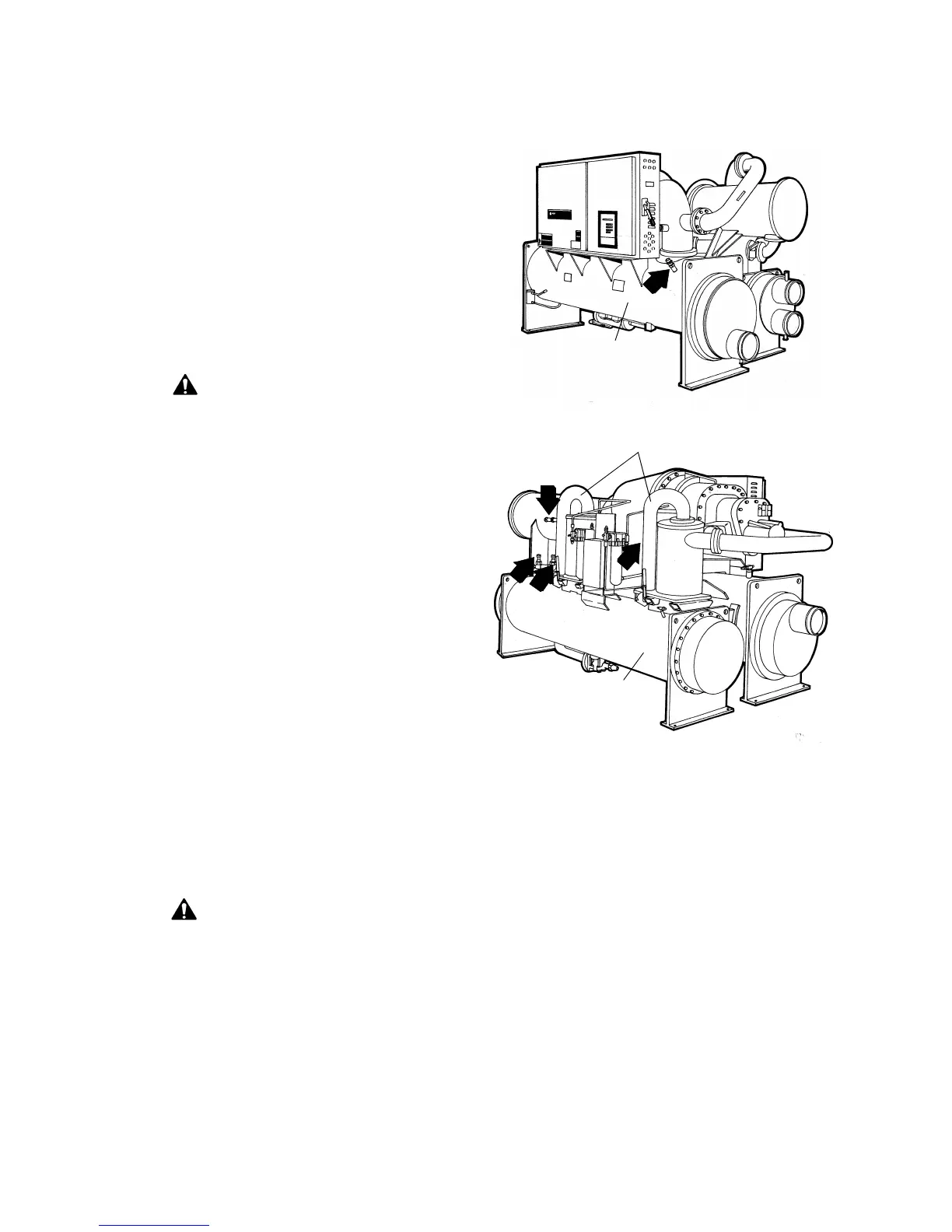

All RTHC units use evaporator, compressor, and

condenser pressure relief valves (

Figure 17

) that

must be vented to the outside of the building.

Relief valve connection sizes and locations are

shown in the unit submittals. Refer to local codes for

relief valve vent line sizing information.

CAUTION: Do not exceed vent piping

code specifications. Failure to heed

specifications could result in capacity

reduction, unit damage and/or relief

valve damage.

Relief valve discharge setpoints and relief rates are

given in

Table 12

. Once the relief valve has opened,

it will reclose when pressure is reduced to a safe

level.

Figure 17

Relief Valve Locations

NOTE: Once opened, relief valves tend to leak and

must be replaced.

Pressure relief valve discharge setpoints and relief

rates will vary with shell diameter and length and also

compressor displacement. Relief rates should be

calculated as required by ASHRAE Standard 15-94

Evaporator Shell

Condenser Shell

Discharge Pipes

*

* Valve is hidden by pipe

Loading...

Loading...