4 - 6 RTHC-IOM-1C

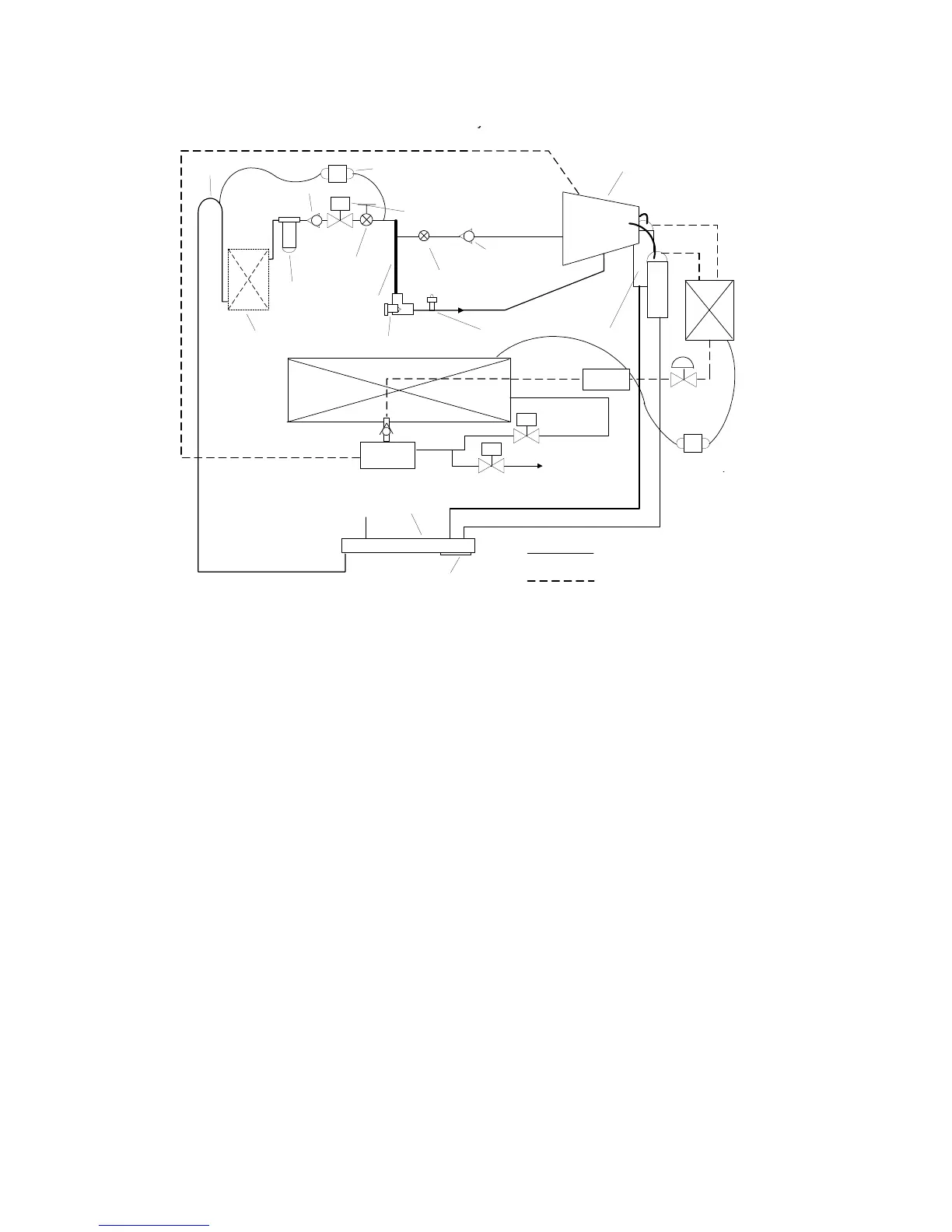

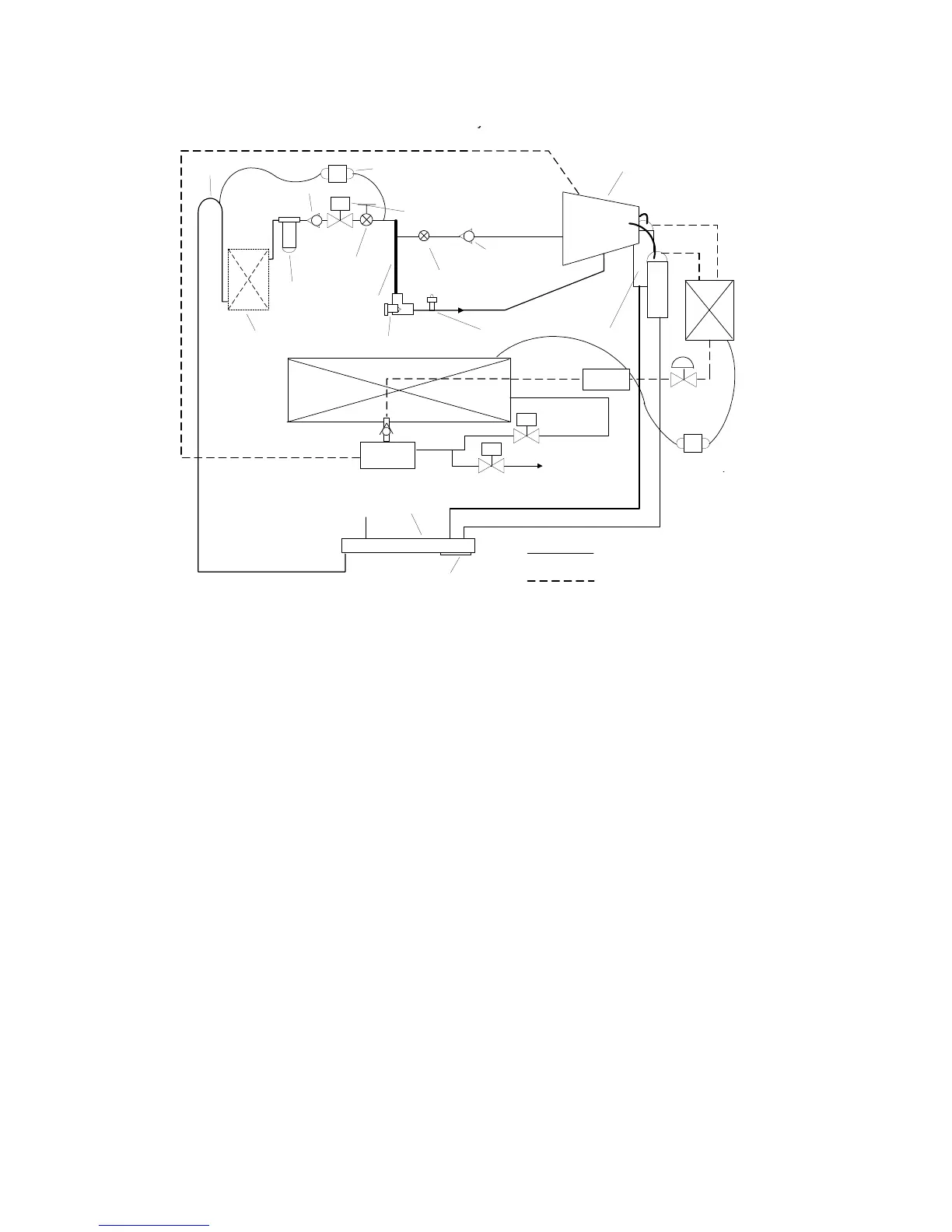

Figure 28

Oil Flow Diagram

Oil that collects in the oil tank sump is at condensing

pressure during compressor operation; therefore, oil

is constantly moving to lower pressure areas.

Oil Flow Protection

Oil flowing through the lubrication circuit flows from

the oil sump to the compressor (see

Figure 28

). As

the oil leaves the oil sump, it passes through two

service valves, an oil cooler (if used), oil filter, and

master solenoid valve. Oil flow then splits into two

distinct paths, each performing a separate function:

(1) bearing lubrication and cooling, and (2)

compressor oil injection.

Oil flow and quality is proven through a combination

of a number of sensors, most notably two differential

pressure switches and the optical oil level sensor.

If for any reason oil flow is obstructed because of a

plugged oil filter, closed service valve, faulty master

solenoid, or other source, a differential pressure (DP)

switch will give a “high” reading (as factory-

calibrated) and shut down the chiller. The differential

pressure switch is factory set to open and trip on a

pressure rise above 20 psid for systems without an

oil cooler and 35 psid for systems with an oil cooler.

Likewise, the optical oil level sensor can detect the

lack of oil in the primary oil system (which could

result from improper oil charging after servicing, or oil

logging in other parts of the system). The sensor can

prevent the compressor from starting or running

unless an adequate volume of oil is present. The

combination of these two devices, as well as

diagnostics associated with extended low system

differential pressure and low superheat conditions,

can protect the compressor from damage due to

severe conditions, component failures, or improper

operation.

If the compressor stops for any reason, the master

solenoid valve closes; this isolates the oil charge in

the sump during “off” periods. The check valves in

the primary oil system prevent reverse flow that the

solenoid valve may be unable to contain or “injector-

to-bearing” oil flow immediately following compressor

shutdown. Such flows would otherwise clear out oil

from the lines and the oil sump, which is an

undesirable effect.

To ensure the required system differential pressure is

adequate to move oil to the compressor, the UCP2

monitors both the 7.7 psid differential switch mounted

between the evaporator and the condenser and the

temperature sensors mounted in both the evaporator

Evaporator

Compressor

Restrictor

Orifice

Oil Sump

Oil Filter

Optional Oil

Cooler

Oil Heater

Trap

Master Oil Line

Solenoid

Oil Separators

Optical Oil

Detector

Vent

Oil Charging

Service Port

To Bearings

Injection to

Rotors

Check Valve

Oil Return

Gas Pump

Vent Line

To Condenser

Pressure

Oil/Refrigerant Mixture

Oil Recovery

Fill Solenoid

Valve

Drain Solenoid

Valve

Oil/Refrigerant

Mixture

Condenser

EXV

Primary Oil System

Refrigerant & Oil Mixture-

Oil Recovery System

Oil Flow

Loss DP

Switch

Check Valve

Manual

Service

Valve

Large

capacity

vertical line

Low Diff

Rfgt Pres

Switch

LVS

Loading...

Loading...