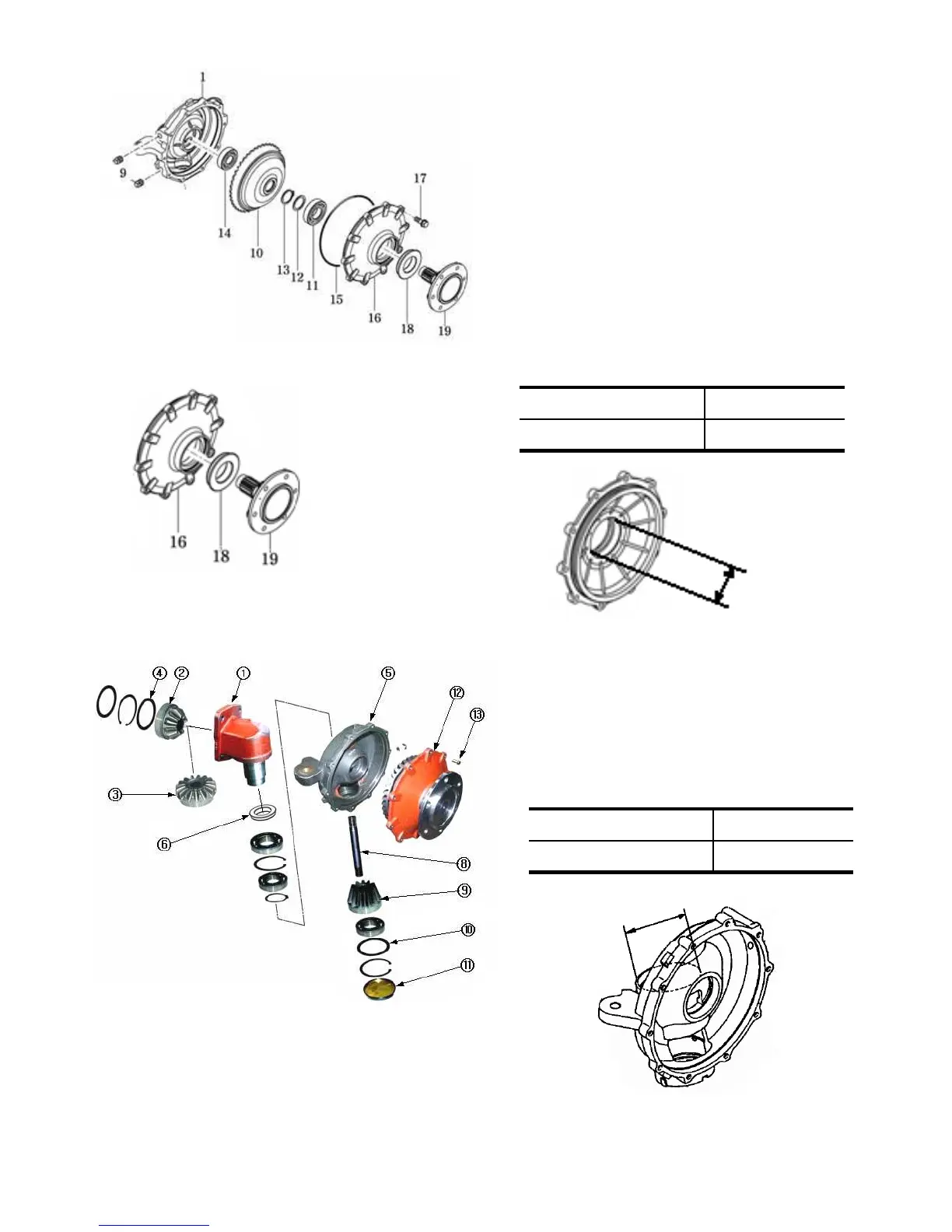

7) Remove the stop ring and the wheel shaft can

be extracted.

Fig.6-21

Fig.6-22

Note:

The removed cap(55) (black plug) should be

discarded and replaced when reassembled.

3.2 INSPECTION

1) Wheel shaft cover

- Inspect mechanical oil seal, O-rings, Gears,

cases, etc. and replace them if worn or damaged.

-Measure the diameter the part which makes

contact with the wheel shaft, with a micro-meter

or vernier-calipers. When the measured value

less than the usable limit, replace the wheel shaft

cover.

Standard value 72

Usable limit 72.05

6-12

8) Remove the seal from the wheel shaft cover

Fig.6-23

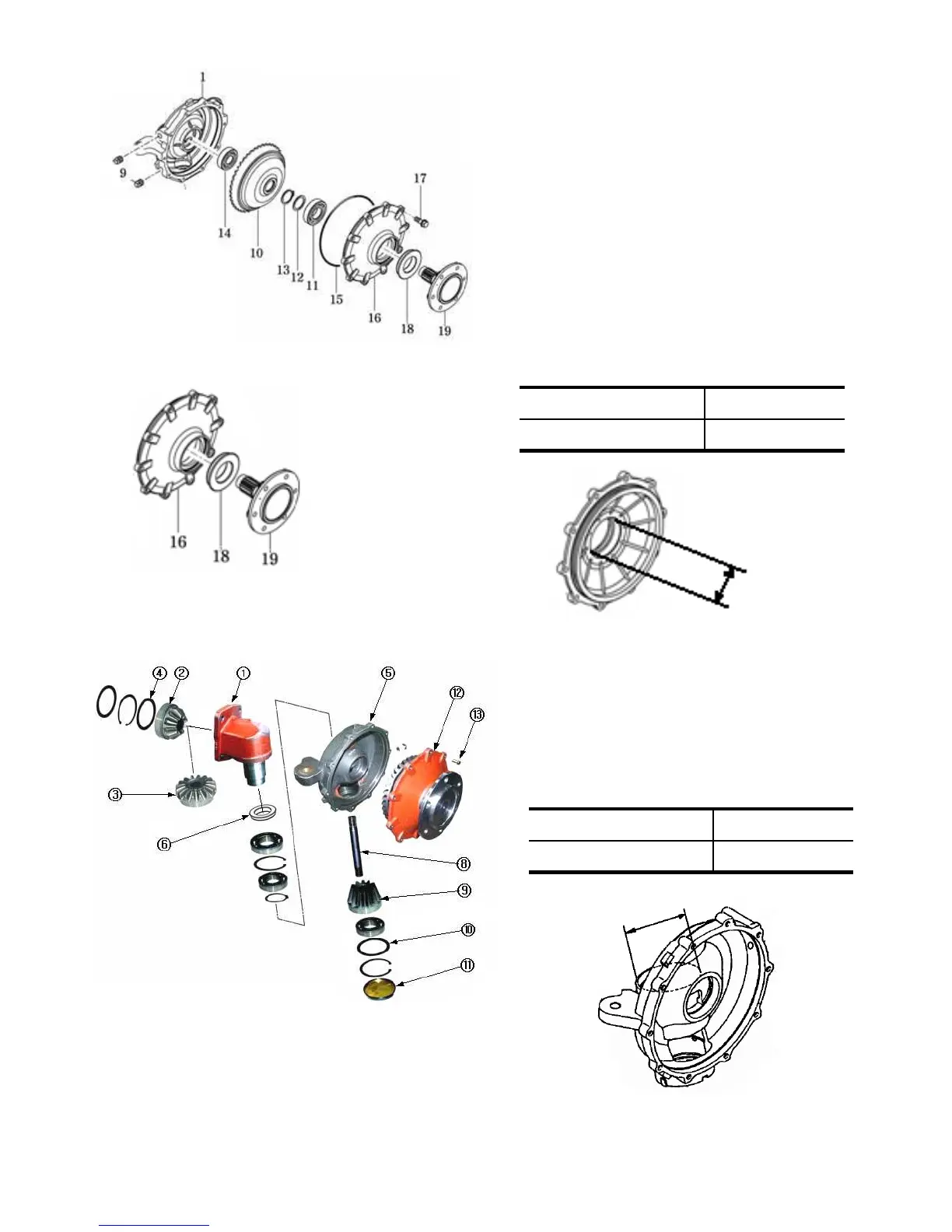

9) Remove the cap (11) from the bottom of the

final case B and detach the snap ring(hole).

Then the counter shaft(8) and BRG can be

removed.

2) Final Drive case (B)

-Measure the diameter the part which makes

contact with the Final drive case (A), with a

micro-meter or vernier-calipers. When the

measured value less than the usable limit,

replace the wheel shaft cover.

Standard value 75

Usable limit 75.05

Fig.6-25

Fig.6-24

Loading...

Loading...