Engine room, ventilation and sound proofing

110

Make sure the necessary room is available for service

and repair. Also make sure that all hatches are proper-

ly sealed off.

Soundproofing

The drive package must be installed in such a way as

to minimise noise and vibration. The noise that occurs

is airborne noise and structural noise (vibration).

Structural noise

Vibration from the engine is transmitted via the engine

mountings and the engine bed to the hull. Other routes

are via the transmission and propeller systems, ex-

haust pipe, coolant pipes, fuel pipes, electrical cables

and control cables.

Pressure pulses from the propeller are transmitted

through the water and into the hull. Pulsed force on

the propeller enters the hull via support blocks, bear-

ings and seals.

Airborne noise

This section refers to airborne noise from the engine

bay. The most important measure to lower airborne

noise from the engine room is to seal the room proper-

ly. Further improvements in noise level reduction can

be achieved by sound insulation material and by de-

signing sound traps for the air inlets.

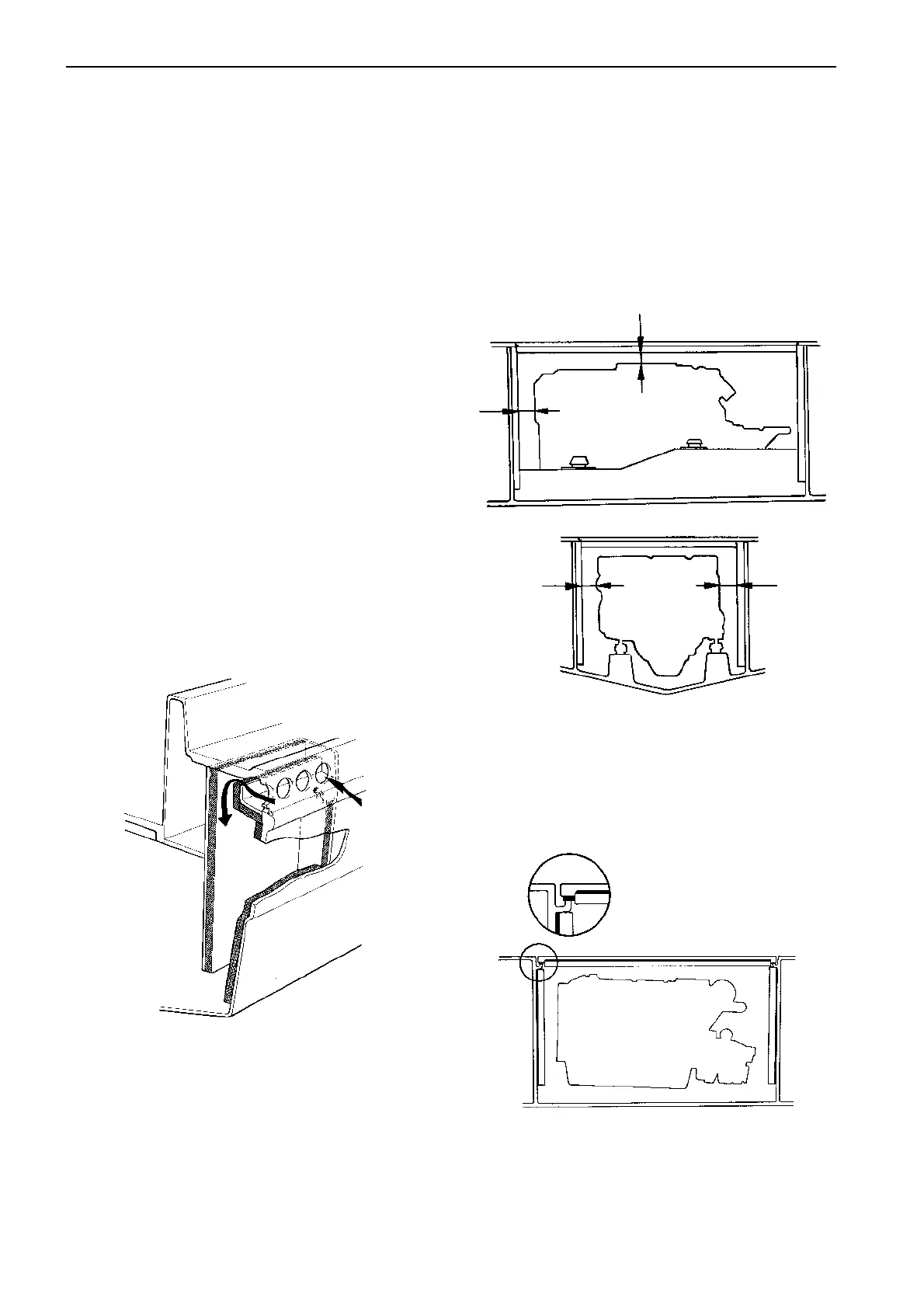

The engine installation should be soundproofed in or-

der to obtain a noise level that is as low as possible.

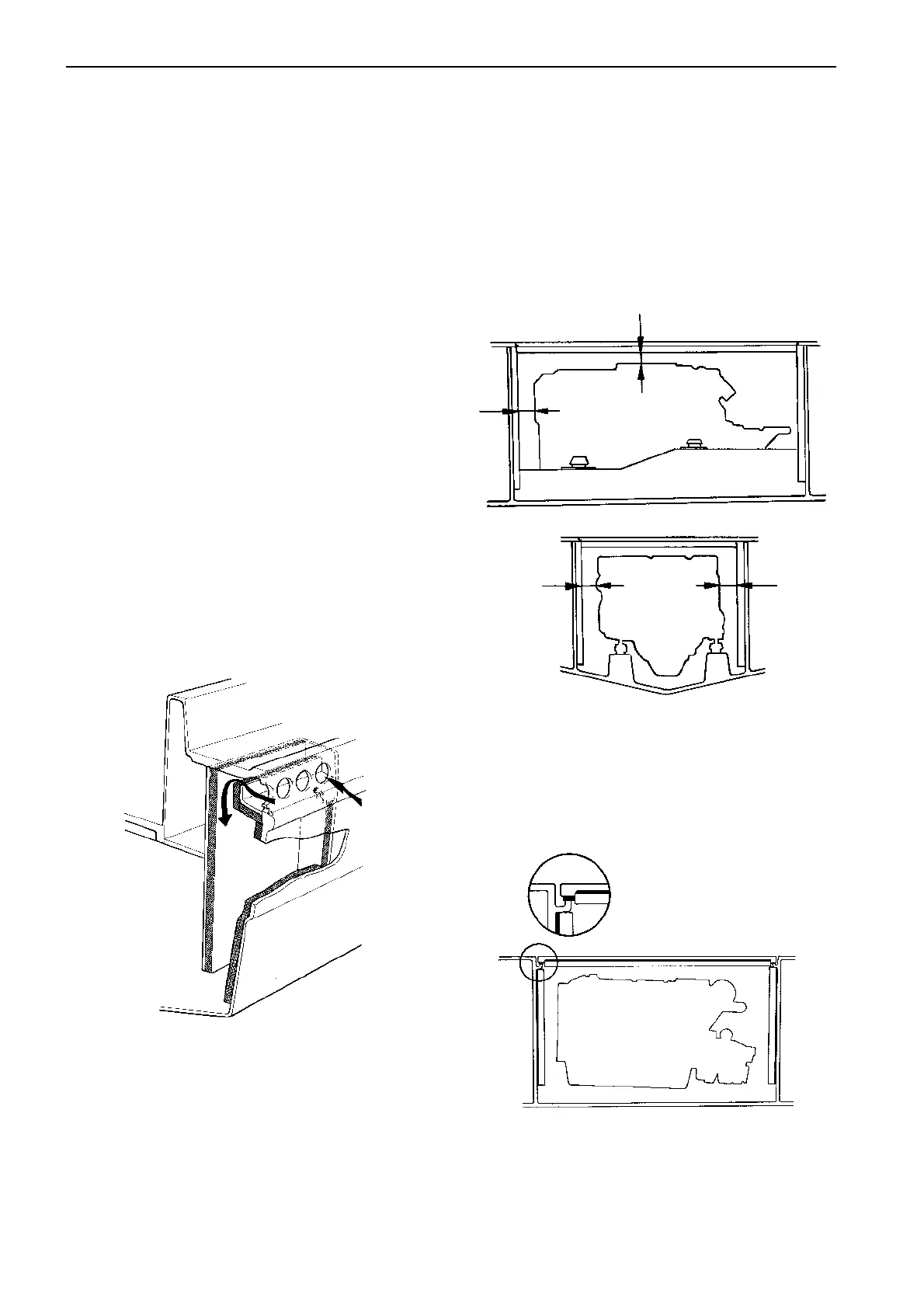

Build the engine compartment with sound traps. Differ-

ent types of sound traps can be selected. The figure

reflects a type that is also provided with drainage.

Furthermore, due consideration must be given to the

thickness of the insulation material.

Prior to installing the insulation material, make sure

that there is sufficient room for checking, service and

repair and for the engine movements during operation.

Also make sure that all hatches are properly sealed

off.

Greatest possible care must be given to the task of

screening the sound source as well as possible.

Screen all the way down to the hull but leave a small

distance to prevent bilgewater from penetrating insula-

tion material.

Cracks, openings etc. must be carefully sealed off

with insulation material. In cases where the engine is

installed under the floor, dress all bulkheads and floor-

boards.

Loading...

Loading...