Fuel system

52

NOTE! All tanks must be provided with at least one

baffle plate for each 150 litres (37 US gal) of volume.

Check if there are special restrictions about volumes

and baffle plates.

Filling and venting connections must not be posi-

tioned on the side of the tank.

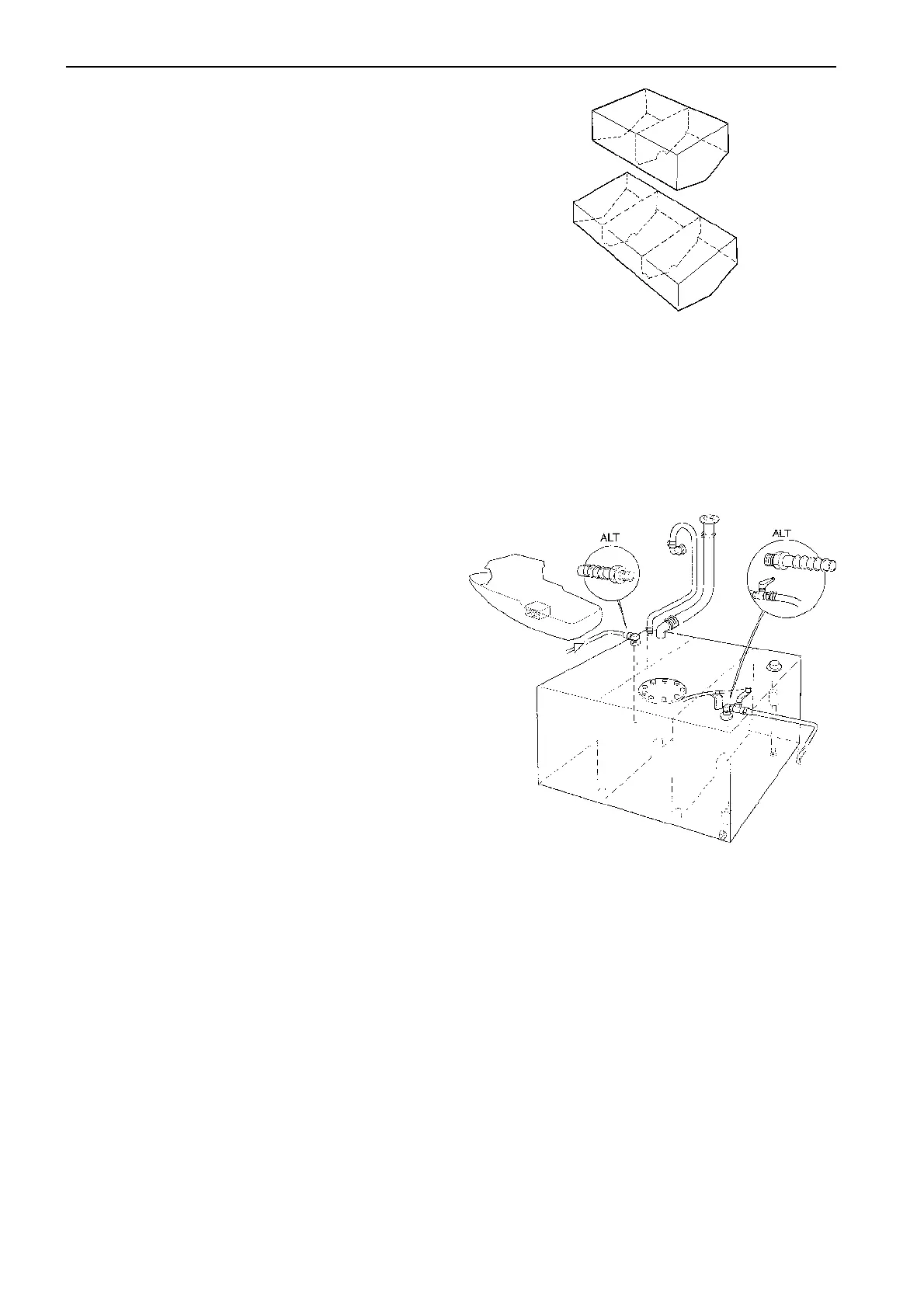

The fuel tank has connections for filling, venting, suc-

tion line, return line, sender for tank gauge and an in-

spection hatch with cover. The suction line and the re-

turn line should be separated as shown in the figure.

A shut-off valve must be installed in the suction line

as close to the tank as possible. The shut-off valve

may have a remote controlled shut-off function by

means of a push-pull cable for example. Certain mar-

kets require electrically controlled shut-off valves.

The fuel return line on diesel engines must be drawn

back to the bottom of the tank in order to avoid air

from entering the fuel system when engine is stopped.

Double tanks should be connected at bottom by

means of pipelines fitted with shut-off cocks. The low-

er connecting pipe should have an internal diameter of

at least 1" so that the tanks can be filled from either

side of the boat. Other fuel tank shapes that are

adapted to the installation geometry are of course ac-

ceptable. Whatever shape is chosen, it is important to

design the tank to provide a low part where water and

sludge can be drained

NOTE! An extra fuel filter with water separator must

be installed for all Volvo Penta engines.

If a day tank is installed, then it is advisable to con-

nect the return line to this tank.

A shut-off valve must be installed in the supply pipe,

between the tank and the filter. This tap should be

able to be shut from a location outside the engine

room.

Stainless steel or aluminum sheet metal is a suitable

material for fuel tanks.

Fuel tanks

If possible, the tanks should be located so that they

are at the same level or somewhat higher than the en-

gine. If they are placed lower, due attention must be

paid to the maximum suction height of the feed pump

which is approx. 1.5 m (5’) for all engines. Note that

the suction height must be calculated from the lower

end of the suction pipe, i.e. 25 mm (1") above the bot-

tom of the tank.

The return pipe should be installed away from the

suction pipe and about 15 mm (0.6") above the tank

bottom to prevent air from entering when the engine is

switched off.

If the tanks are located lower than the level permitted

by the suction height of the fuel feed pump, then the

fuel is to be pumped up to a day tank by means of a

hand pump or power pump. Return fuel from the en-

gine is taken in this case to the day tank.

If the fuel tank maximum level is higher than 3.5 m

above the injection pump on the engine, shut off

valves should be fitted on the fuel and return line. The

valves should be shut off during permanent engine

stop. The maximum static pressure the fuel system

can withstand is 0.5 bar (7.2 psi). There is otherwise

a risk that fuel may leak through the injection pump to

the lubricating system.

Loading...

Loading...