Propeller shaft systems

44

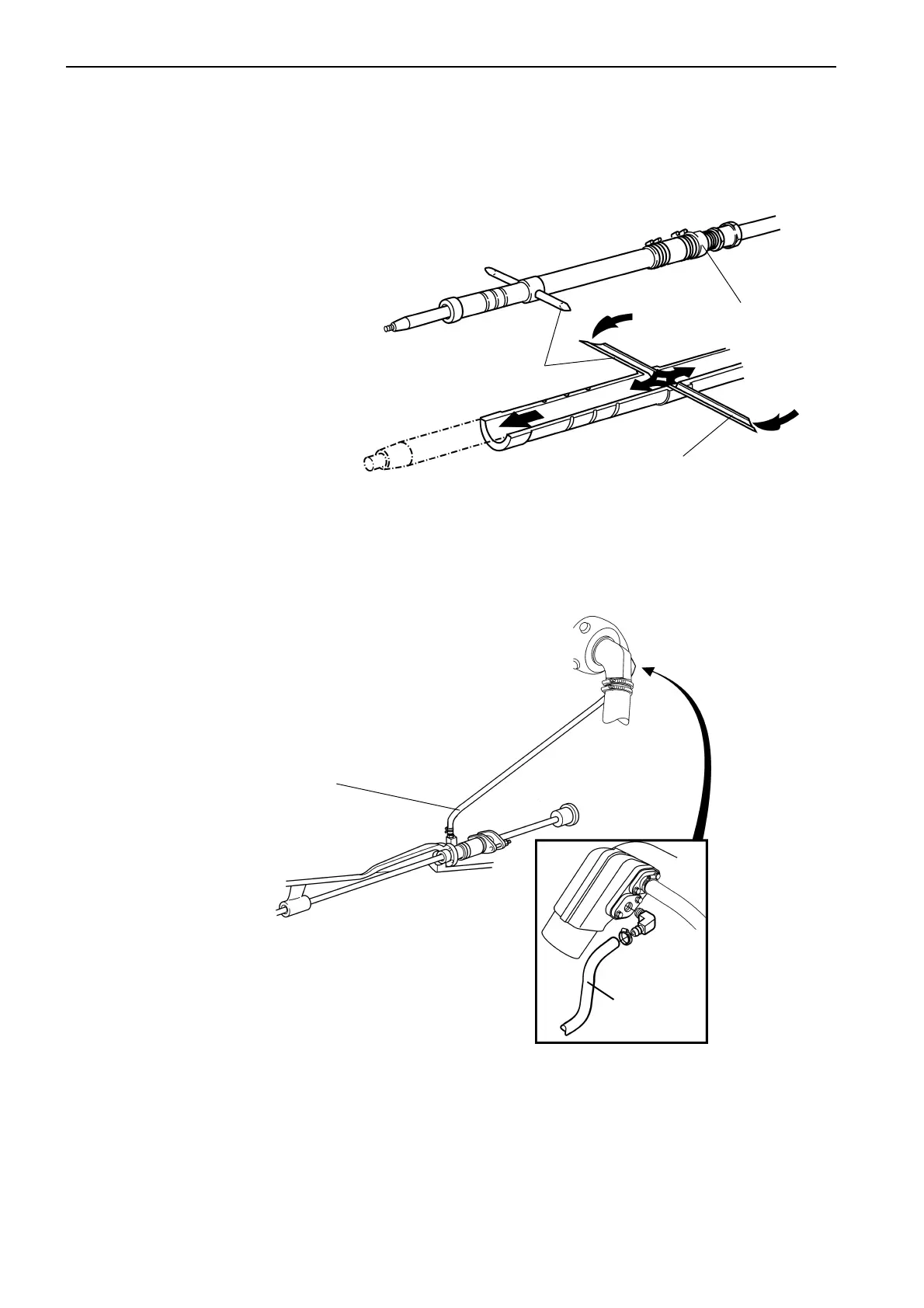

Another way, which is common in planing boats, is to

feed the shaft seal with water taken from the cooling

system of the engine. Make sure not to bleed off too

much water. If too much water is lost through the out-

let to the shaft seal, the exhaust hose might be over-

heated.

At the front of the exhaust elbow there is a cover

plate. This could be drilled and tapped for fitting a

hose connection. A guideline is to install a 10 mm (3/

8”) hose from the exhaust elbow.

It is important to check that the water lubrication is

adequate, also at full speed, while testing a new in-

stallation.

Shaft seals

There are different methods of lubrication for the shaft

seal. The two most common are water and grease lu-

bricated seals. Ensure easy access for maintenance

and inspection of the seal. Some seals require a cer-

tain clearance to the gearbox coupling in order to per-

mit replacement of packing without disconnecting the

shaft.

Water lubricated shaft seal

With water lubricated seal the water has two purpos-

es, lubricating and cooling the seal. Water could be

supplied to the water lubricated shaft seal in different

ways.

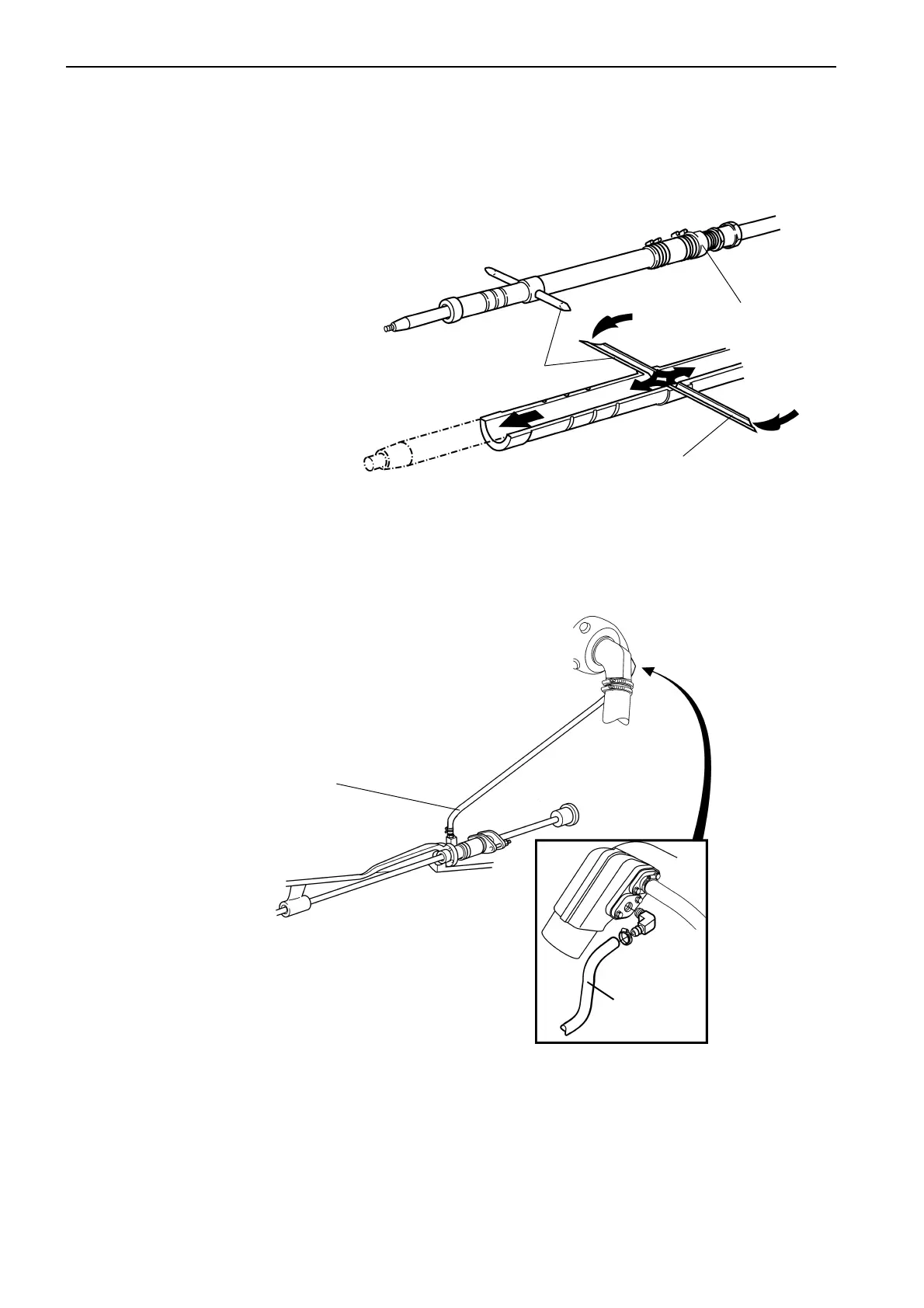

One way, which is suitable in displacement boats, is

to feed it from water pick up pipes in the stern tube.

The feed pipes should be designed to build up pres-

sure through the boats motion in water.

It is important to check that the water lubrication is

adequate, also at full speed, while test running a new

installation. Make sure that the pipes (2) allow enough

water to flow in.

1

2

2

1. Shaft seal

2. Feed pipes

Water from exhaust

elbow.

Hoose/pipe diam. max.

10 mm (3/8")

Diam. max.

10 mm (3/8")

Loading...

Loading...