Cooling system

61

Freshwater system

The freshwater is circulated via the cooling ducts and

heat exchanger of the engine by a centrifugal pump.

As long as the coolant is cold, the thermostat(s) re-

main closed, preventing the coolant from passing to

the heat exchanger. Instead the coolant flows in a by-

pass duct directly back to the suction side of the

pump. This ensures that the engine rapidly reaches its

working temperature. The thermostats also maintain

proper temperature at low power/load.

Coolant

If a cooling system is to function well, it is very impor-

tant that the coolant is treated correctly so that no

corrosion or lime scale forms in the cooling system.

NOTE! Always use Volvo Penta anti-freeze or anti-

corrosion agent. Both are available in concentrated

form. Mixing with other makes of coolants can impaire

corrosion protection, which may damage the engine or

block the cooling system.

Water quality

Always use clean water that complies with the require-

ments in ASTM D4985 X1.1. If these requirements

are not met, corrosion may occur, which could lead to

impaired cooling performance.

Specification:

Solid particles < 340 ppm

Total hardness < 9.5° dH

Chloride < 40 ppm

Sulphate < 100 ppm

pH value < 5.5 – 9.0

Silica < 20 mg SiO

2

/lit.

Iron < 0.10 ppm

Magnese < 0.05 ppm

Conductivity < 500 µS/cm

Organic content COD

Mn

< 15 mg kMnO

4

/lit.

If the water cannot be cleaned to fullfil the require-

ments de-ionised water or distilled water should be

used. Volvo Penta ready-mixed coolant can also be

used.

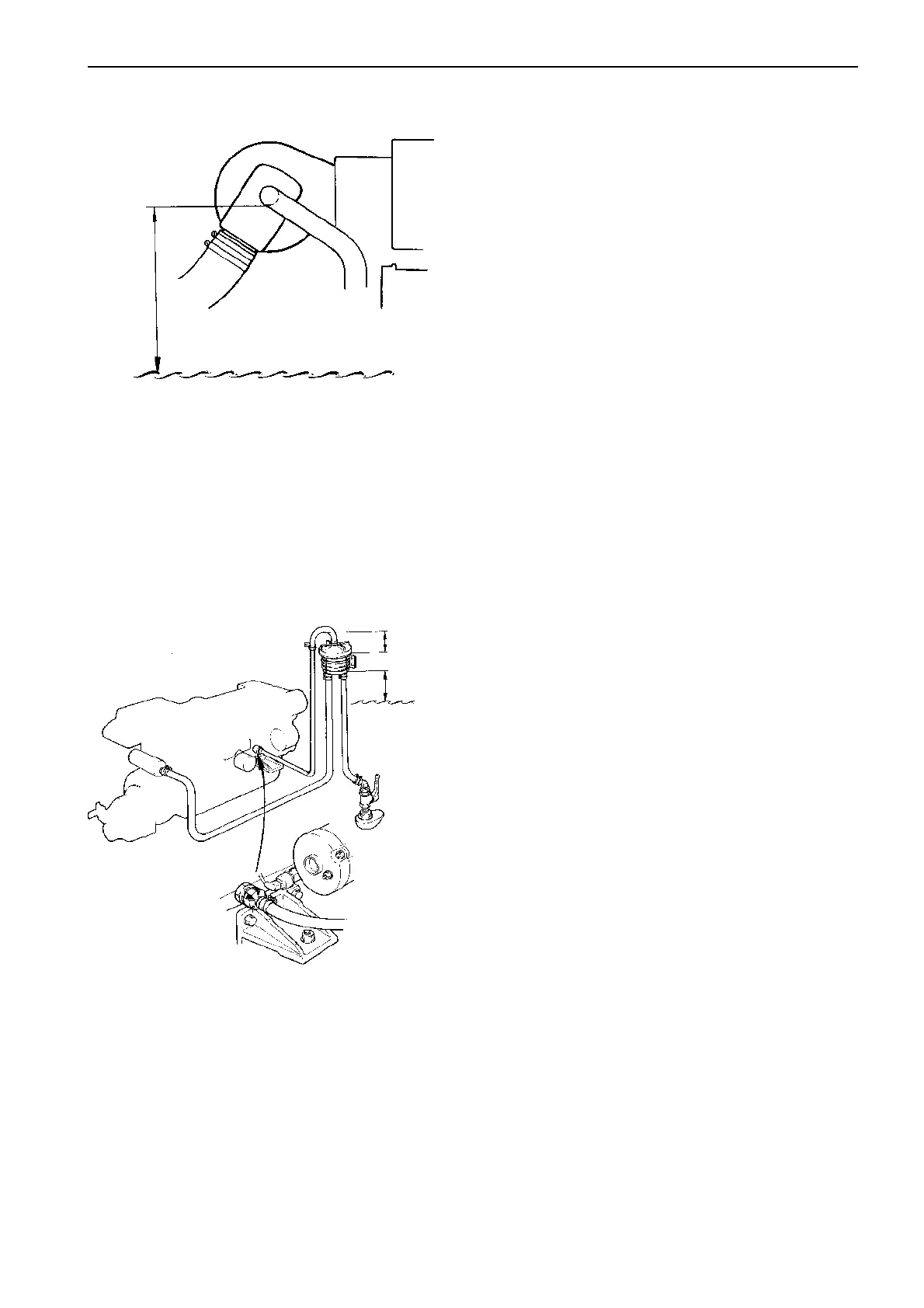

Make sure that there is a space of 150 mm (6")

above the filter to permit routing of house to the anti-

siphoning valve.

150 mm

Min 200 mm

(8")

200 mm

(8")

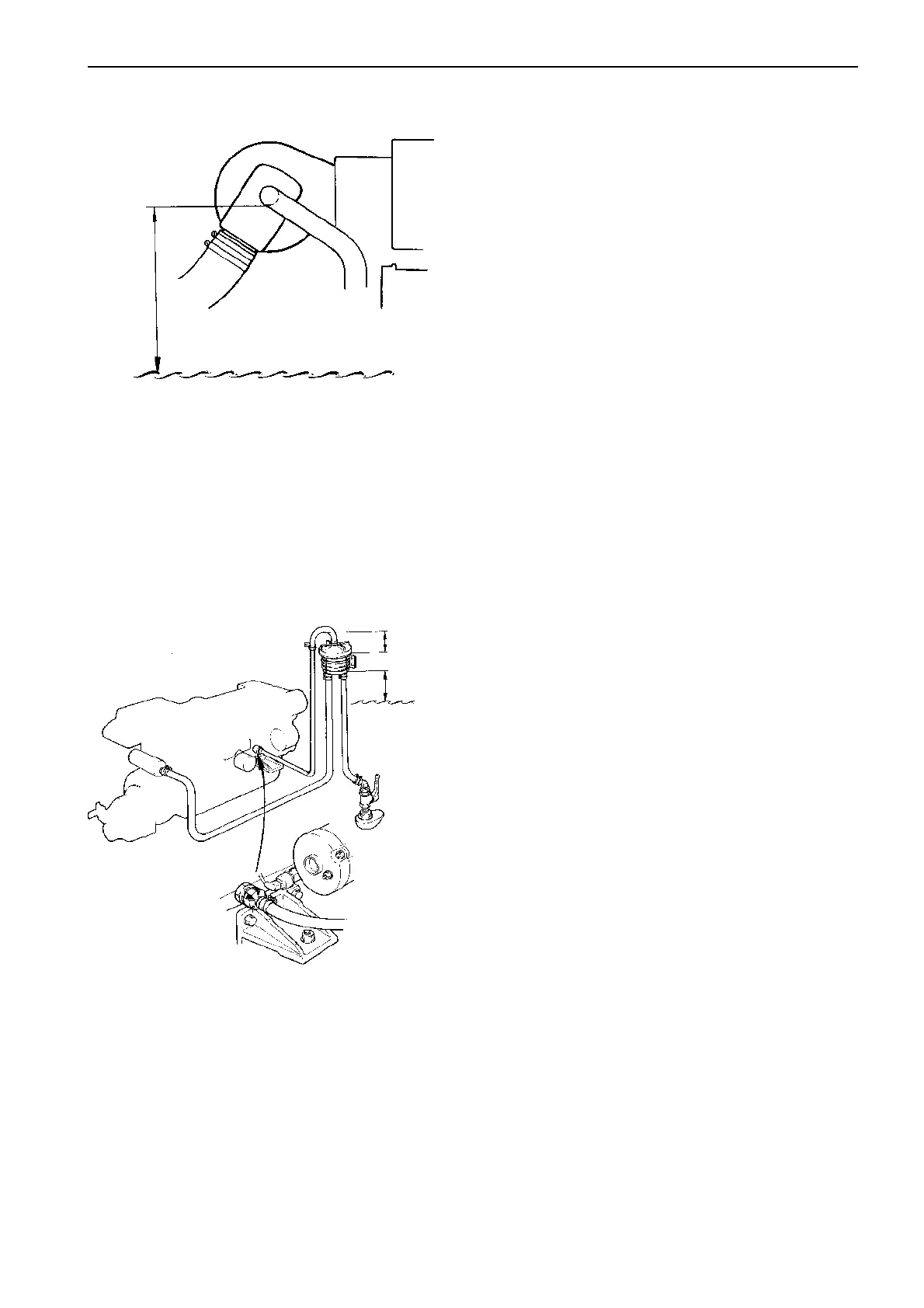

Anti-siphoning valve

The anti-siphoning valve (vacuum valve) should be

fitted in cases where the engine is installed so deep in

the boat that the distance between the exhaust pipe

flange (lower part) and water-line is less than 200 mm

(8"). When correctly fitted the valve prevents

siphoning, which causes water entry into the engine.

Loading...

Loading...