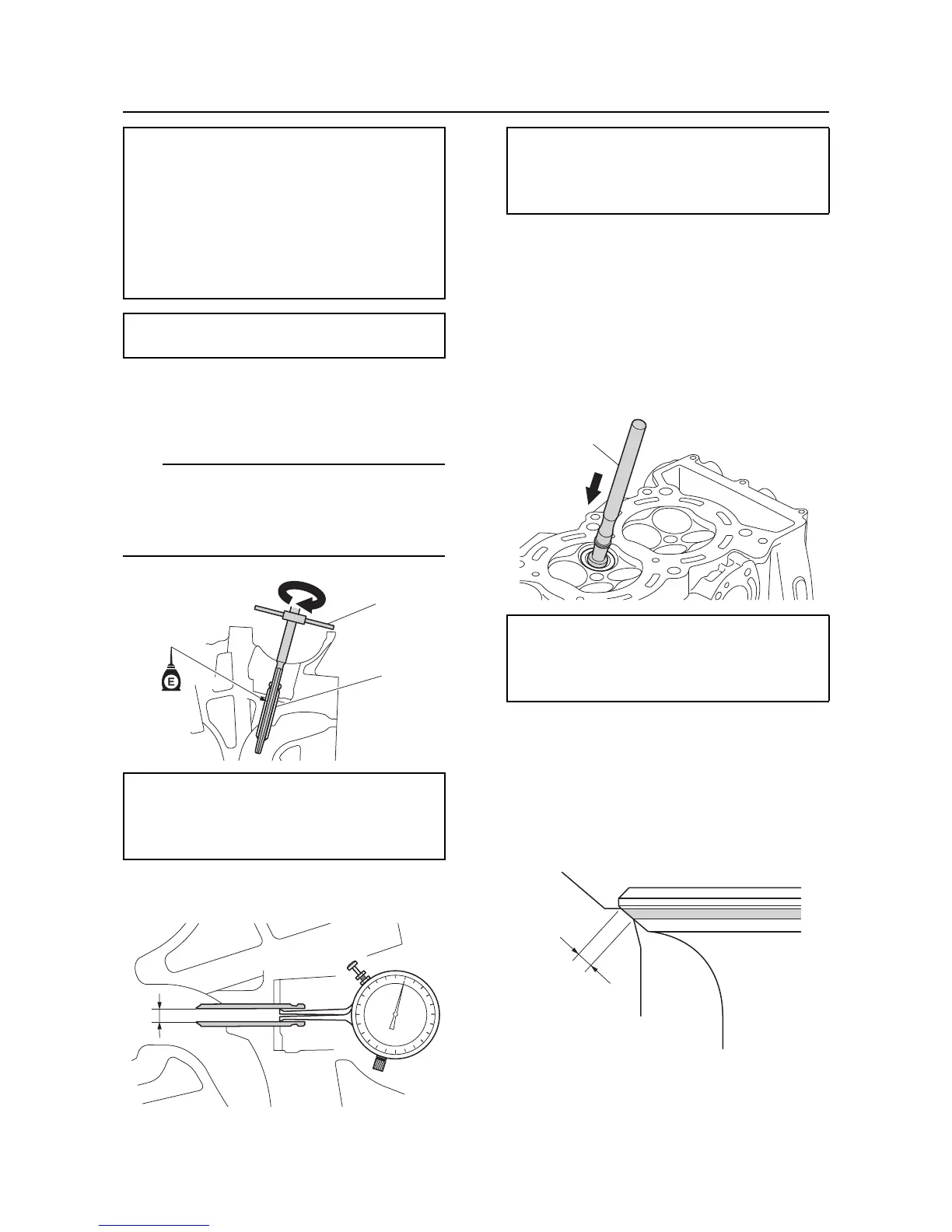

• Turn the special service tool “1” clockwise to

ream the valve guide “2”.

• Do not turn the special service tool “1” coun-

terclockwise when removing the tool.

4. Clean the valve guide inner surface. Mea-

sure the valve guide inside diameter “a”.

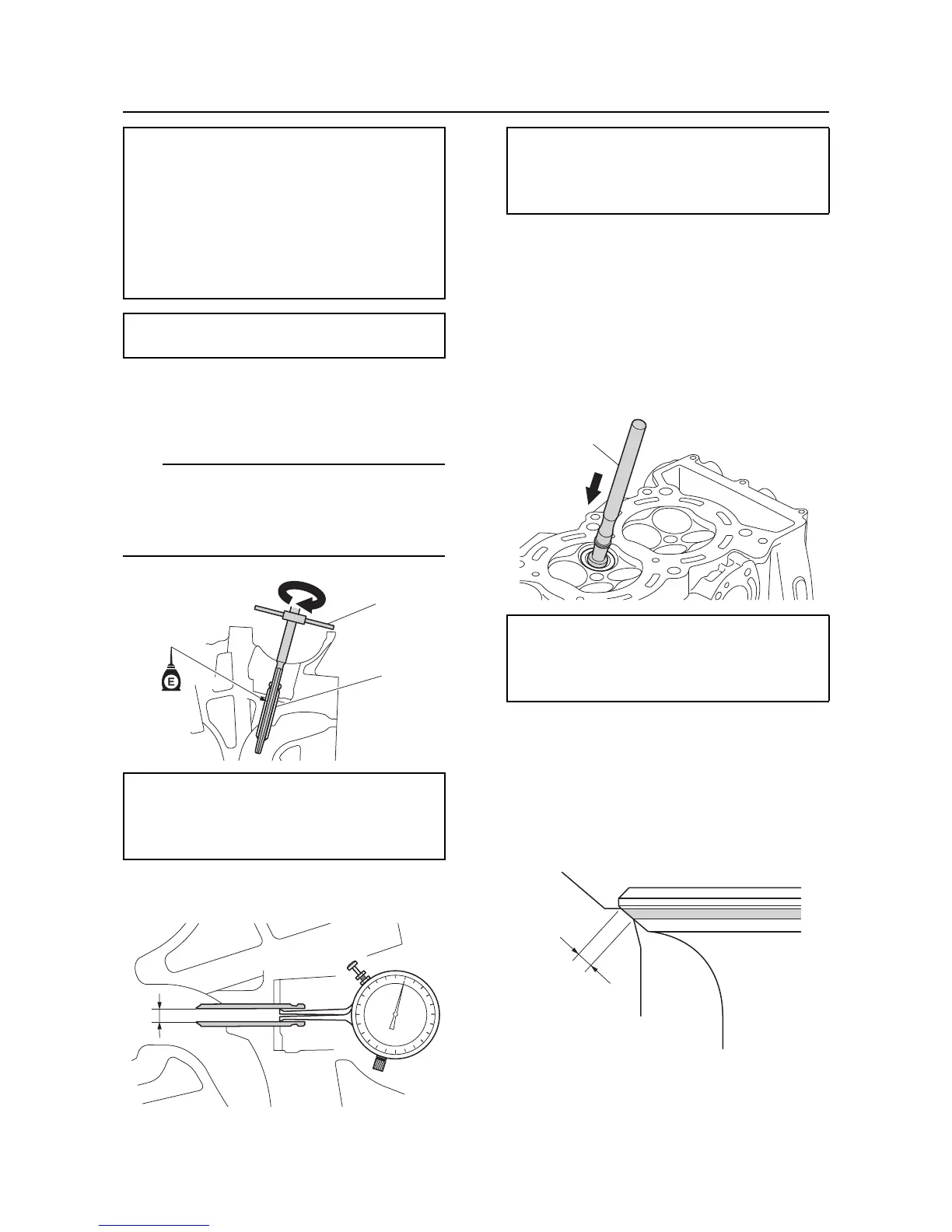

Valve seat check

1. Remove carbon deposits from the valves

and valve seats.

2. Apply a thin, even layer of blue layout fluid

(Dykem) onto the valve seat.

3. Press the valve lightly against the valve

seat using the special service tool “1”.

4. Measure the valve seat contact width “a”

where the blueing dye is adhered to the

valve face. Reface the valve seat if the

valve is not seated properly or if the valve

seat contact width “a” is out of specifica-

tion. Replace the valve guide if the valve

seat contact width “a” is uneven.

Valve guide remover/installer “1”

90890-06801

Valve guide remover “1”

YB-06801

Valve guide installer “2”

90890-06810

Valve guide installer “2”

YB-06810

Valve guide installation height

12.3–12.7 mm (0.48–0.50 in)

Valve guide reamer “1”

90890-06804

Valve guide reamer “1”

YM-01196

Loading...

Loading...