Periodic service

3-10

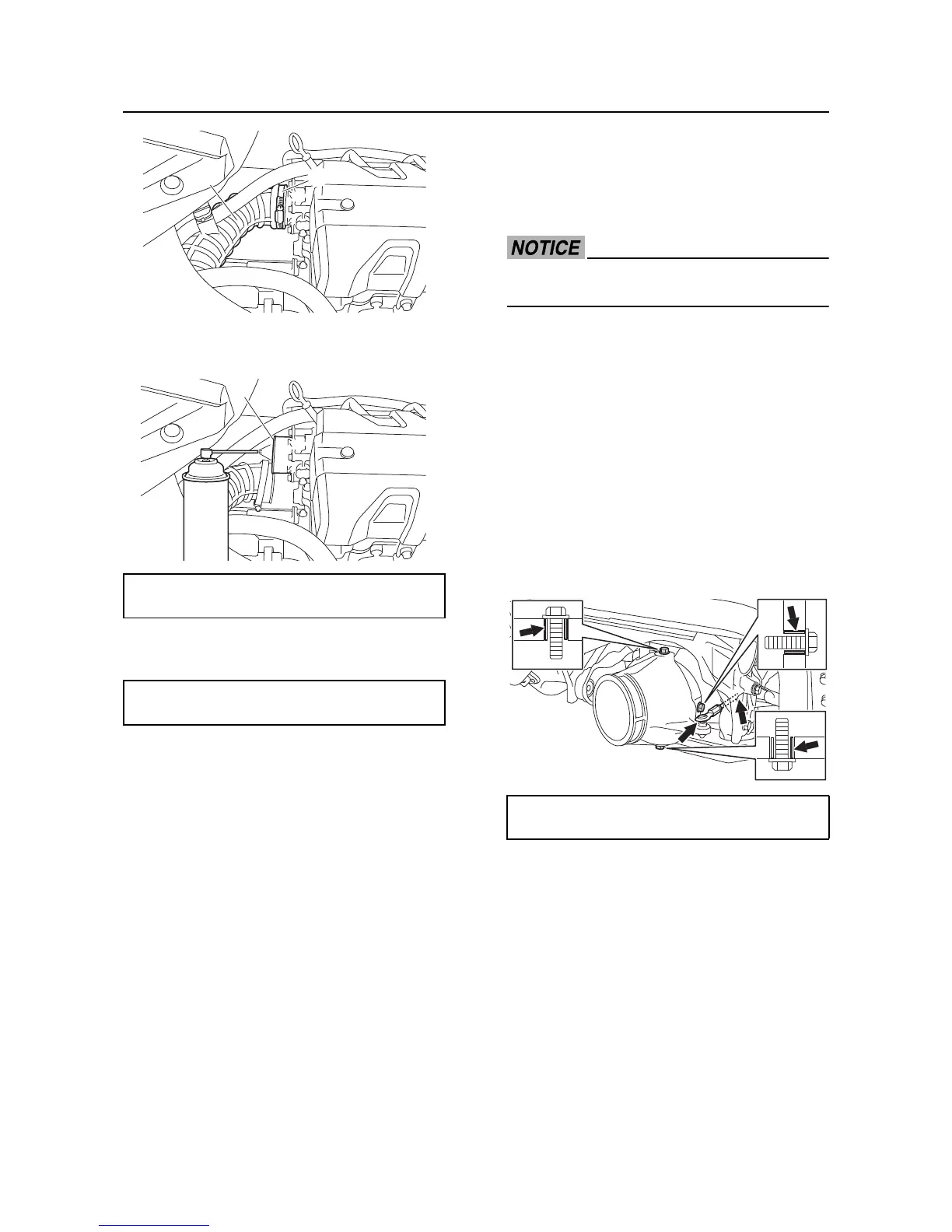

2. Spray a rust inhibitor into the throttle valve

opening “a”.

3. Connect the air intake pipe, and then tight-

en the air intake pipe clamp.

Exhaust system check

1. Check the exhaust hoses and hose con-

nections for exhaust or cooling water leak-

age. See “Exhaust system installation”

(8-24).

2. Check the exhaust hoses. Replace if

cracked or damaged.

3. Check the exhaust hose routing and the

clamps.

Breather hose check

1. Check the breather hoses and hose con-

nections for blowby gas or oil leakage. See

“Cable and hose routing” (2-13).

2. Check the breather hoses. Replace if

cracked or damaged.

3. Check the breather hose routing and the

clamps. See “Cable and hose routing”

(2-13).

Impeller check

Make sure to remove the battery before

checking the jet pump unit.

1. Check the impeller from the jet intake side.

Clean if there is foreign material.

2. Check the impeller. Replace if bent or

damaged. See “Jet pump unit removal”

(6-3).

Jet thrust nozzle check

1. Disconnect the trim rod and steering cable.

2. Remove the jet thrust nozzle and nozzle

ring.

3. Apply grease to the nozzle pivot.

4. Check that the jet thrust nozzle moves

smoothly.

5. Install the nozzle ring and jet thrust nozzle.

6. Connect the trim rod and steering cable.

Jet vacuum bilge draining system

check

1. Check the bilge strainer “1”. Clean if

clogged or dirty.

Recommended lubricant

Rust inhibitor

Air intake pipe clamp

3.5 Nm (0.35 kgf·m, 2.58 ft·lb)