Crankcase, connecting rod, and piston

5-82

2. Place the cylinder block upside down on a

bench.

3. Install the crankshaft bearings “1” into the

cylinder block and crankcase.

• Install the crankshaft bearings “1” in their

original positions.

• Fit the protrusion “a” on each bearing into the

slots “b” in the cylinder block and crankcase.

4. Install the crankshaft.

5. Put a piece of Plastigauge “1” on each

crankshaft journal, parallel to the crank-

shaft.

Do not put the Plastigauge “1” over the oil hole

in the main journals of the crankshaft.

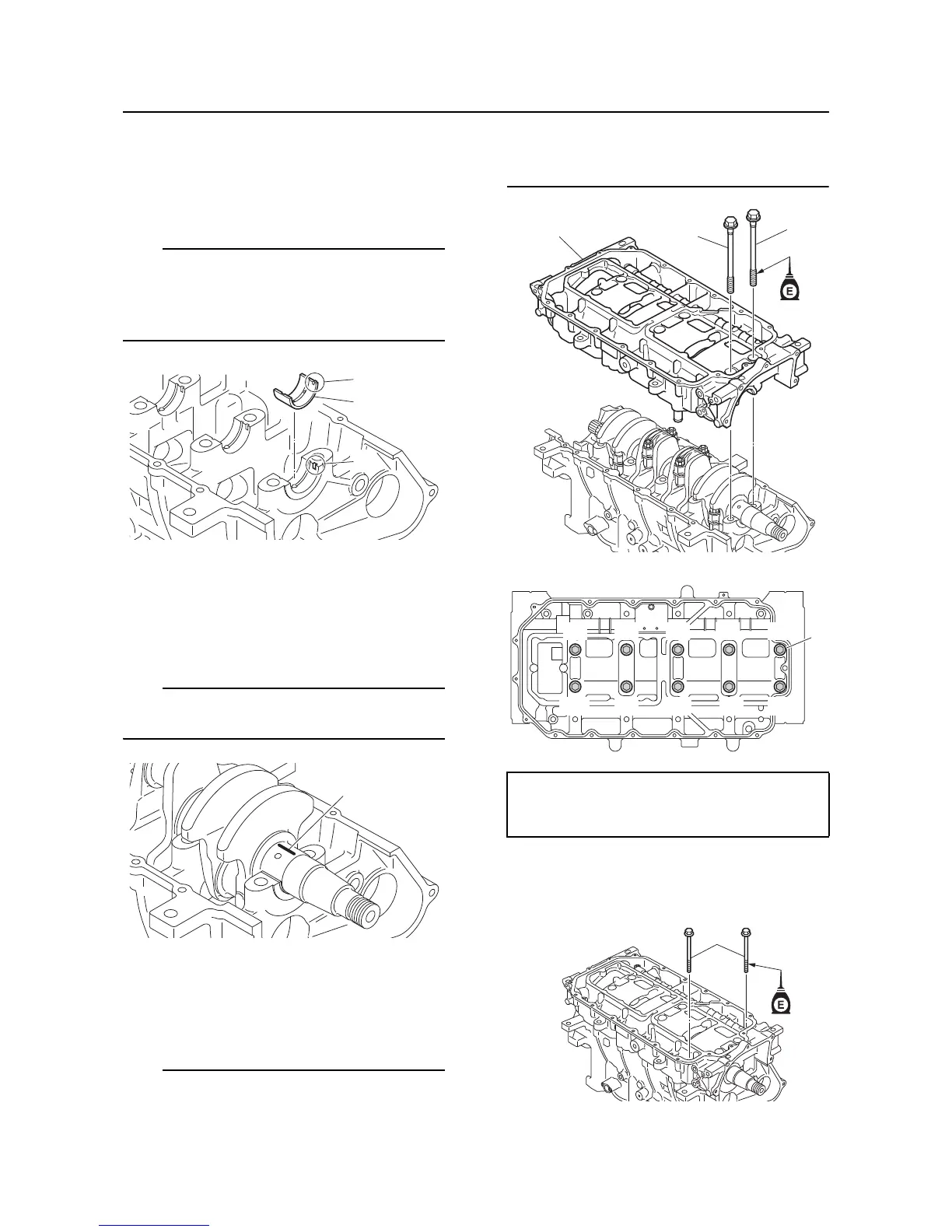

6. Install the crankcase “1” and crankcase

bolts “2”, and then tighten the crankcase

bolts “2” to the specified torques in 2 stag-

es and in the order [1], [2], and so on.

• When checking the journal oil clearance, re-

use the removed crankcase bolts “2”.

• Do not turn the crankshaft until the journal oil

clearance measurement has been complet-

ed.

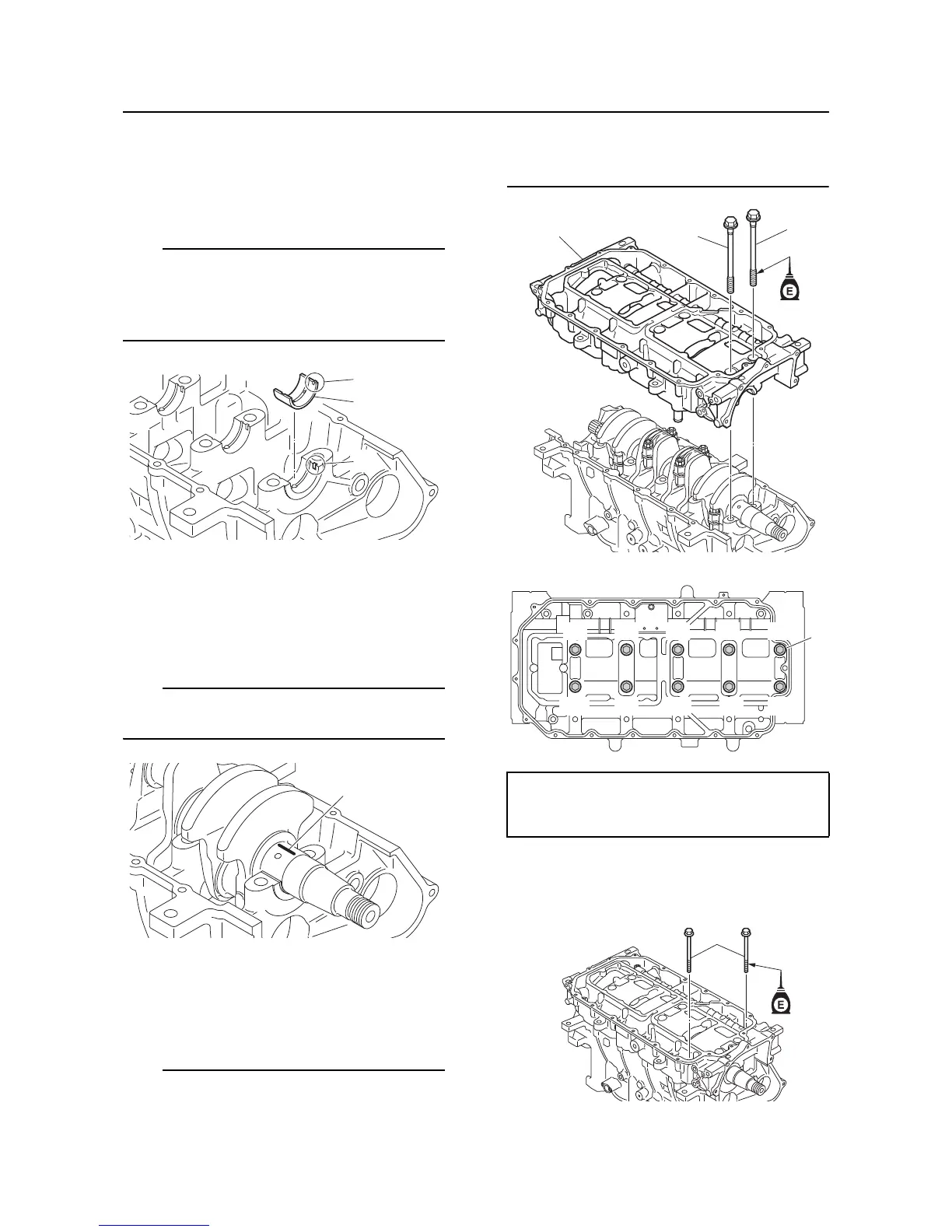

7. Install the crankcase bolts “1”, and then

tighten them to the specified torque in the

order [1], [2], and so on.

Crankcase bolt “2”

1st: 30 Nm (3.0 kgf·m, 22.1 ft·lb)

2nd: 90°

2

[7] [5] [1] [

3]

[9]

[8][6][2][4]

[10]

Loading...

Loading...