Chapter 3 Fuel Injection Equipment

5. Injection Pump Construction and Operation

5.

Injection

Pump

Construction

and

Operation

i 4LHA Series

Governor

spring

Flyweight

Control

lever /

Control

lever shaft ^^/^

Idling

spring

Full-load

adjusting screw

Regulating

valve

Tension

lever

'Governor

iever assembly

Plunger

barrel

Delivery

valve

Cross

coupling

Control

sleeve

Plunger

spring

Cam

disk

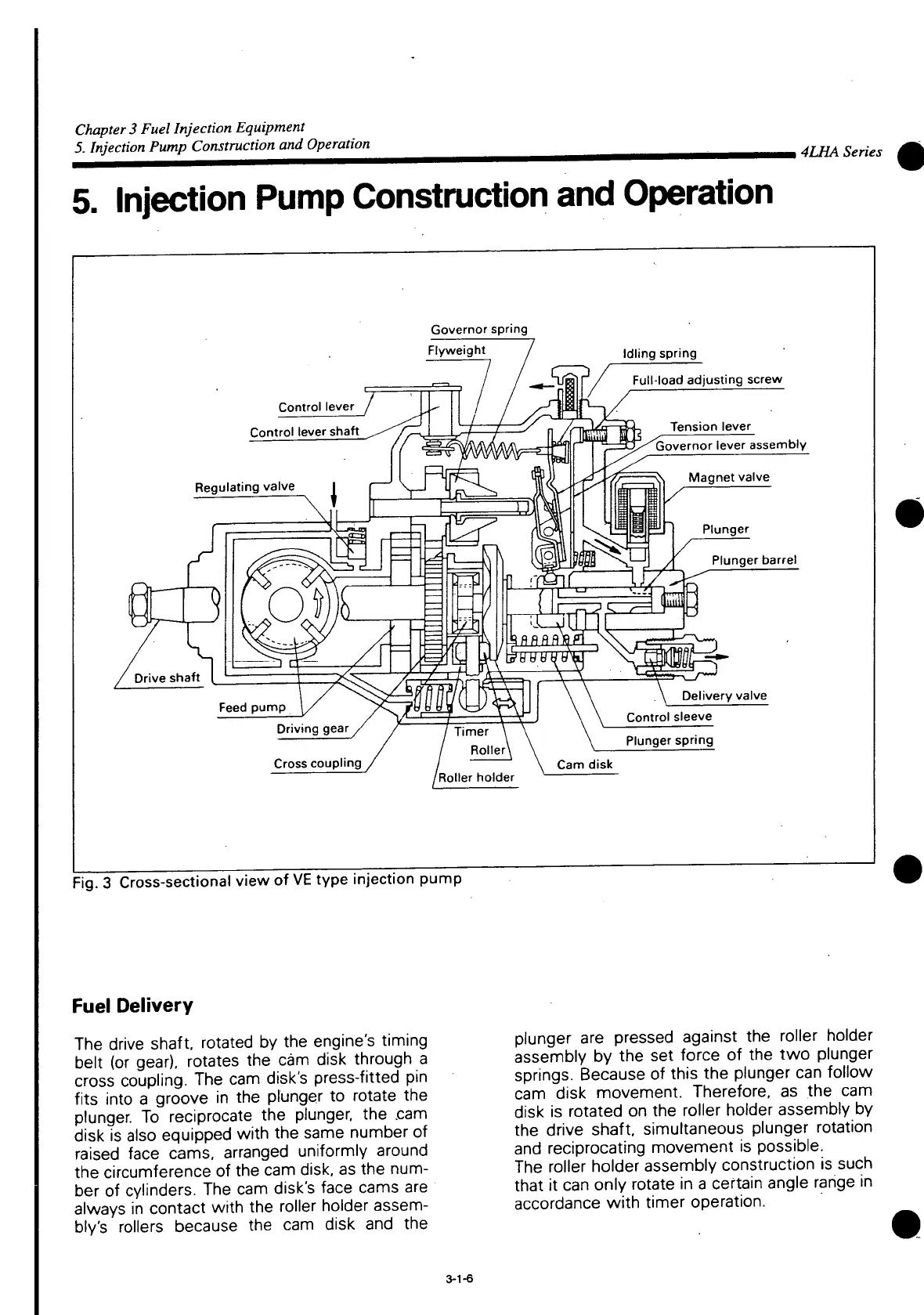

Fig.

3

Cross-sectional

view of

VE

type injection pump

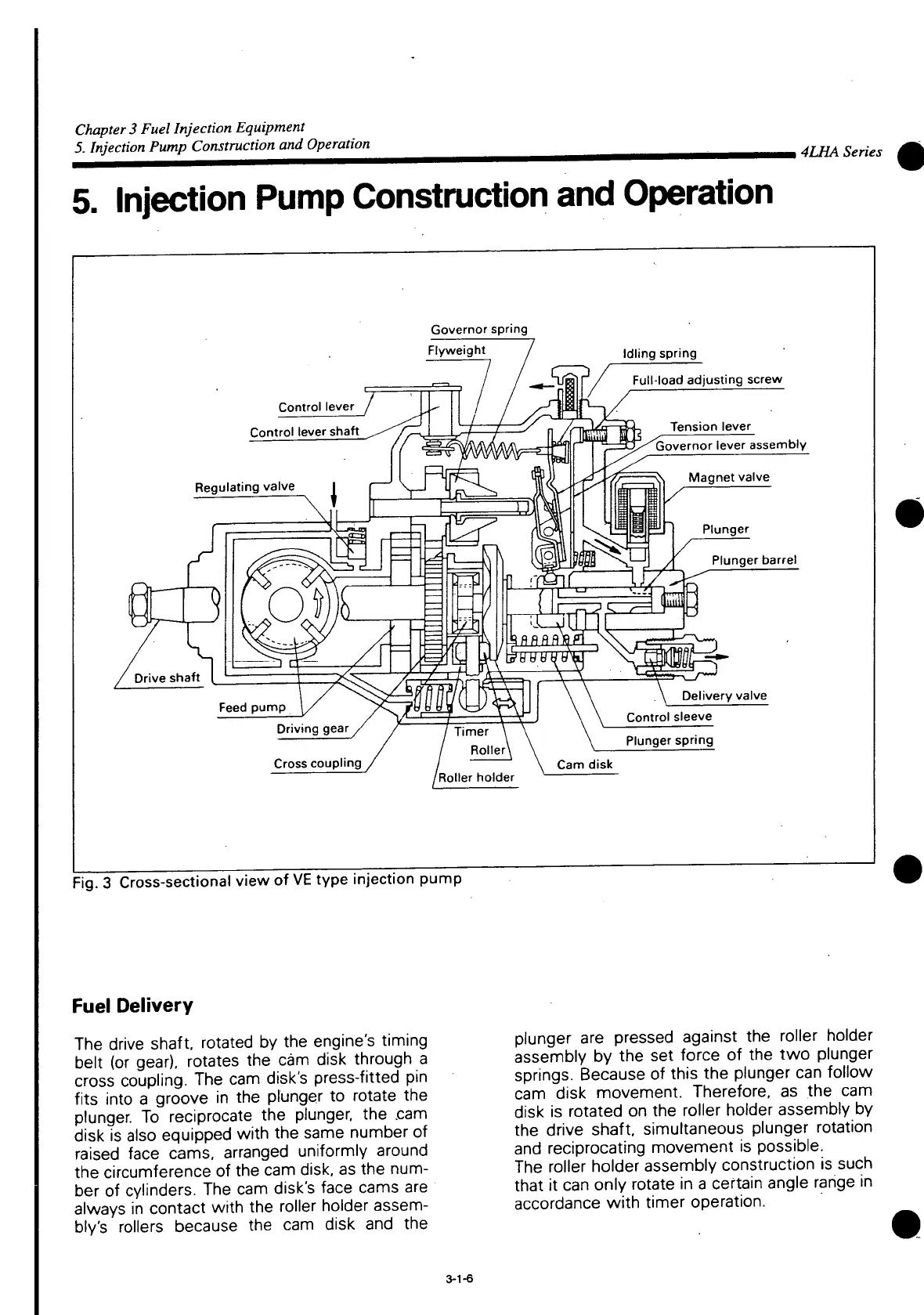

Fuel

Delivery

The

drive shaft, rotated by the engine's

timing

belt (or gear), rotates the cam disk through a

cross

coupling. The cam disk's press-fitted pin

fits

into

a groove in the plunger to

rotate

the

plunger. To reciprocate the plunger, the .cam

disk

is also equipped

with

the same number of

raised

face

cams,

arranged uniformly around

the circumference of the cam disk, as the num-

ber

of cylinders. The cam disk's face cams are

always

in contact

with

the roller holder

assem-

bly's

rollers because the cam disk and the

plunger are pressed against the roller holder

assembly

by the set force of the two plunger

springs.

Because

of this the plunger can follow

cam

disk movement. Therefore, as the cam

disk

is rotated on the roller holder assembly by

the drive shaft, simultaneous plunger

rotation

and

reciprocating movement is possible.

The

roller holder assembly construction is such

that

it can only

rotate

in a certain angle range in

accordance

with

timer operation.

3-1-6

Loading...

Loading...