Chapter 3 Fuel Injection Equipment

5. Injection Pump Construction and Operation

14LHA Series

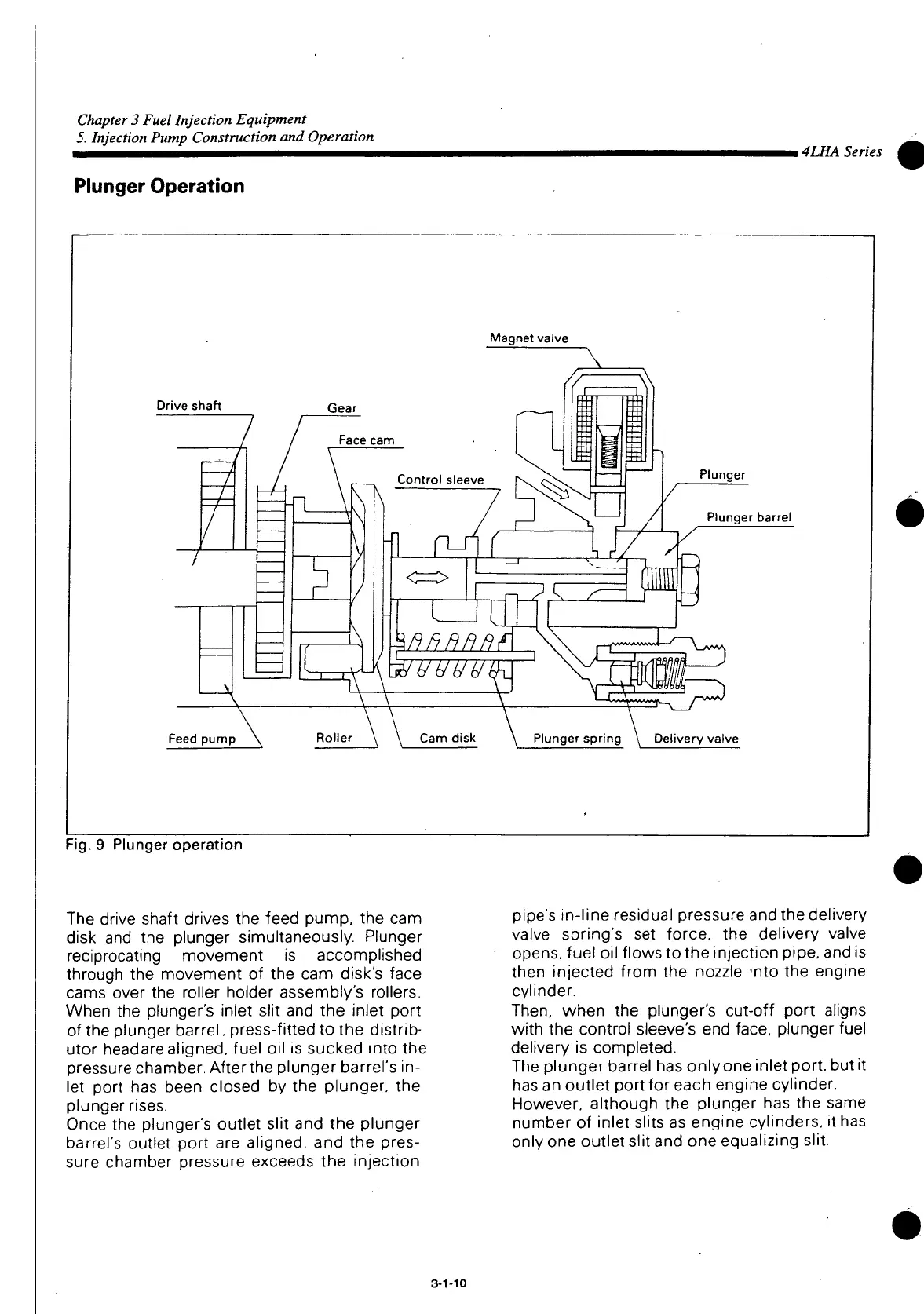

Plunger

Operation

Magnet valve

Drive shaft

Gear

Face

cam

Control sleeve

Feed

pump

Roller

Cam

disk

Plunger

Plunger

barrel

Plunger

spring \ Delivery valve

Fig.

9

Plunger

operation

The drive shaft drives the "feed pump, the cam

disk and the plunger simultaneously. Plunger

reciprocating movement is accomplished

through the movement of the cam disk's face

cams

over the roller holder assembly's rollers.

When the plunger's inlet slit and the inlet

port

of the plunger barrel, press-fitted to the distrib-

utor headare aligned, fuel oil is sucked

into

the

pressure

chamber. Afterthe plunger barrel's in-

let

port

has been closed by the plunger, the

plunger

rises.

Once

the plunger's

outlet

slit and the plunger

barrel's

outlet

port

are aligned, and the pres-

sure chamber pressure exceeds the injection

pipe's

in-line residual pressure and the delivery

valve spring's set force, the delivery valve

opens,

fuel oil flows to the injection pipe, and is

then injected from the nozzle

into

the engine

cylinder.

Then,

when the plunger's

cut-off

port

aligns

with

the control sleeve's end face, plunger fuel

delivery is completed.

The plunger barrel has only one inlet

port,

but it

has

an

outlet

port

for each engine cylinder.

However, although the plunger has the same

number of inlet slits as engine cylinders, it has

only one

outlet

slit and one equalizing slit.

3-1-10

Loading...

Loading...