Chapter

1

General

6. Piping Diagrams

*4LHA Series

11. Service

Data

•

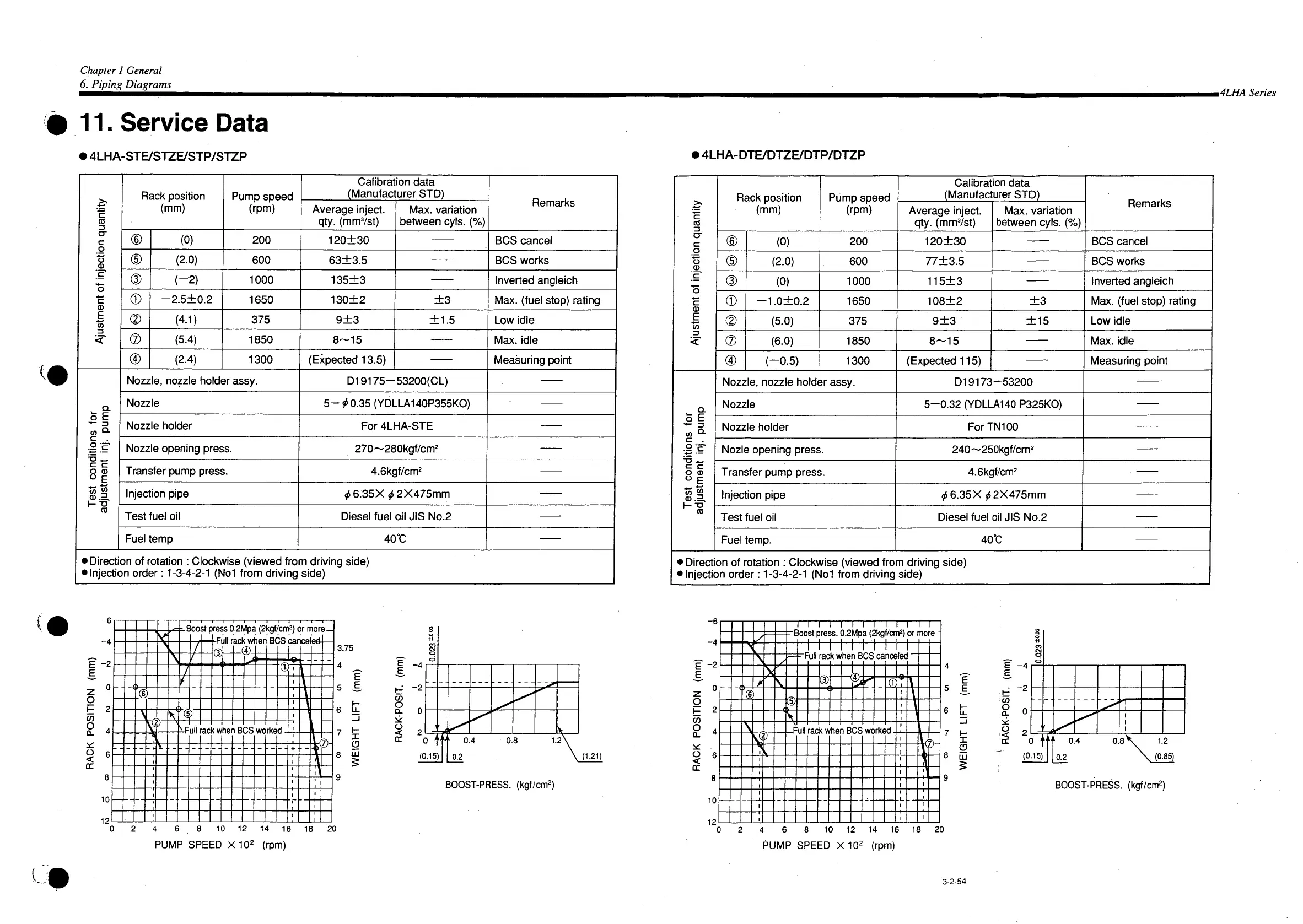

4LHA-STE/STZE/STP/STZP

Ajustment of injection quantity

Rack

position

(mm)

Pump

speed

(rpm)

Calibration

data

(Manufacturer STD)

Remarks

Ajustment of injection quantity

Rack

position

(mm)

Pump

speed

(rpm)

Average

inject,

qty. (mm7st)

Max.

variation

between

cyls.

(%)

Remarks

Ajustment of injection quantity

©

(0)

200

120±30

BCS

cancel

Ajustment of injection quantity

(D

(2.0).

600

63±3.5

BCS

works

Ajustment of injection quantity

(D

(-2)

1000

135±3

Inverted angleich

Ajustment of injection quantity

©

-2.5±0.2

1650

130±2

±3

Max.

(fuel stop) rating

Ajustment of injection quantity

(4.1)

375

9±3 ±1.5

Low

idle

Ajustment of injection quantity

®

(5.4)

1850

8~15

Max.

idle

Ajustment of injection quantity

®

(2.4)

1300

(Expected

13.5)

Measuring

point

Test conditions for

adjustment inj.

pump

Nozzle,

nozzle holder

assy.

D19175-53200(CL)

Test conditions for

adjustment inj.

pump

Nozzle

5-^0.35

(YDLLA140P355KO)

Test conditions for

adjustment inj.

pump

Nozzle

holder

For

4LHA-STE

Test conditions for

adjustment inj.

pump

Nozzle

opening press.

270~280kgf/cm

2

Test conditions for

adjustment inj.

pump

Transfer

pump press.

4.6kgf/cm

2

Test conditions for

adjustment inj.

pump

Injection pipe

?

5

6.35X^2X475mm

Test conditions for

adjustment inj.

pump

Test

fuel oil

Diesel

fuel oil JIS No.2

Test conditions for

adjustment inj.

pump

Fuel

temp 40°C

•

Direction

of rotation :

Clockwise

(viewed from driving side)

• Injection order:

1-3-4-2-1

(Not from driving side)

>

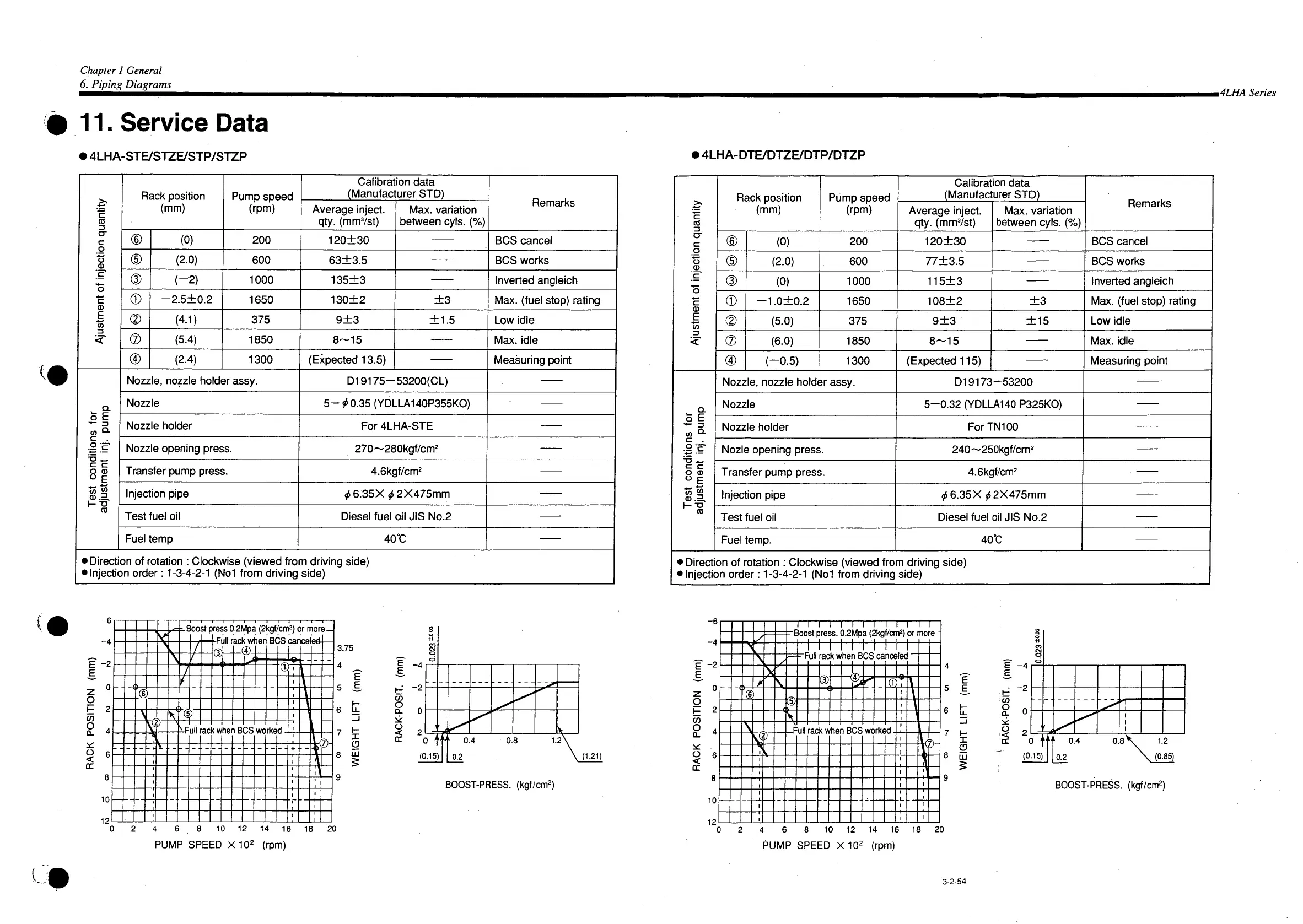

4LHA-DTE/DTZE/DTP/DTZP

Ajustment of injection quantity

Rack

position

(mm)

Pump

speed

(rpm)

Calibration

data

(Manufacturer STD)

Ajustment of injection quantity

Rack

position

(mm)

Pump

speed

(rpm)

Average

inject,

qty. (mmVst)

Max.

variation

between

cyls.

(%)

Remarks

Ajustment of injection quantity

©

(0)

200

120±30

BCS

cancel

Ajustment of injection quantity

©

(2.0)

600

77±3.5

BCS

works

Ajustment of injection quantity

© (0)

1000

115±3

Inverted angleich

Ajustment of injection quantity

©

—1.0±0.2

1650

108±2

±3

Max.

(fuel stop) rating

Ajustment of injection quantity

©

(5.0)

375

9±3 ±15

Low

idle

Ajustment of injection quantity

®

(6.0)

1850

8~15

Max.

idle

Ajustment of injection quantity

®

(-0.5)

1300

(Expected

115)

Measuring

point

Test conditions for

adjustment inj. pump

Nozzle,

nozzle holder

assy.

Dl

9173-53200

Test conditions for

adjustment inj. pump

Nozzle

5-0.32

(YDLLA140

P325KO)

Test conditions for

adjustment inj. pump

Nozzle

holder

ForTN100

Test conditions for

adjustment inj. pump

Nozle

opening press.

240~250kgf/cm

2

Test conditions for

adjustment inj. pump

Transfer

pump press.

4.6kgf/cm

2

Test conditions for

adjustment inj. pump

Injection pipe

^6.35X^2X475mm

Test conditions for

adjustment inj. pump

Test

fuel oil

Diesel

fuel oil JIS No.2

Test conditions for

adjustment inj. pump

Fuel

temp.

40°C

• Direction of rotation :

Clockwise

(viewed from driving side)

• Injection order:

1-3-4-2-1

(Not from driving side)

-4

E

-2

E

0

2

4

6

8

10

12

CO

O

CL

o

<

-E loo St

f

iress

0.2Mpa

(2kgf/cm

2

) or mor

full

mr\f iuhan D^C /-«on^nlrwH

3-

/

(E

i

3-

\

(E

_

J

--

f

/

- ---

'©

- -

\

'd

\

v

>-

Pull

ac

f who

IB

DS

WC

rk«

ac

IB

DS

WC

rk«

f.

\

I)

r r

3.75

4 _

E

5 £

6 t

8 UJ

E

E

co

O

a.

cr

BOOST-PRESS,

(kgf/cm

2

)

2

4 6 8 10 12 14 16 18

PUMP

SPEED

X 10

2

(rpm)

20

-6

-4

E

-2

E.

Z

0

O

i—

2

4

6

8

10

12

CO

O

a.

o

<

1 1 1 1 1 1 1 1 1 1 1 1 1

- t

JOOSI

press,

u.^mpd ^Kgi/cnr-; or nu re

v

Ililllill

\

/

-

F

Ull

rac

KM

nen

e

1

(Jb

ca nee 'iec

\

®

1

--

-(

\

®

f'

-

(D

--

-(

tø

-

t

©

V

t

\

V

F

Ull rac

kw

he

n Rr.fi

WC rkc

•d

\

\

f

Ull rac

kw

he WC rkc

K

D-D-

1

'

:

i

-•

--

1

-•

--

1

i

E

5

E,

6 t

_i

7 I—

I

CD

8 UJ

E

E

8

DC

-4

-2

0

o

-4

-2

0

o

-4

-2

0

o

-4

-2

0

o

0 f

(0.15)

0.4 0.8\

0.2

1.2

\ (0.85)

BOOST-PRESS,

(kgf/cm

2

)

2

4 6 8 10 12 14 16 18 20

PUMP

SPEED

X 10

2

(rpm)

3-2-54

Loading...

Loading...