Chapter 3 Fuel Injection Equipment

7. Fuel Injection Nozzle

4LHA Seri,

7.

Fuel

Injection

Nozzle

When

fuel oil pumped by the fuel injection pump

reaches

the injection nozzle, it pushes up the nozzle

valve

(held down by spring), and is injected into the

combustion chamber at high pressure.

The

fuel is atomized by the nozzle to mix uniformly

with

the air in the combustion chamber. How well

the fuel is mixed

with

high temperature air directly

affects combustion efficiency, engine performance and

fuel economy.

Accordingly,

the fuel injection nozzles must be kept in

top condition to maintain performance and operating

efficiency.

7-1 Functioning of

fuel

injection

nozzle

Fuel

from the fuel injection pump

passes

through th<

oil port in the nozzle holder, and enters the nozzle

body reservoir.

When

oil reaches the specified pressure, it pushes up

the nozzle valve (held by the nozzle spring), and ij

injected through the small hole on the tip of the nozzk

body.

The

nozzle valve is automatically pushed down by th€

nozzle

spring and closed after fuel is injected.

Oil

that

leaks from between the nozzle valve anc

nozzle

body goes from the hole on top of the nozzle

spring through the oil leakage

fitting

and back into the

fuel tank.

Adjustment of injection starting pressure is effected

with

the adjusting shims.

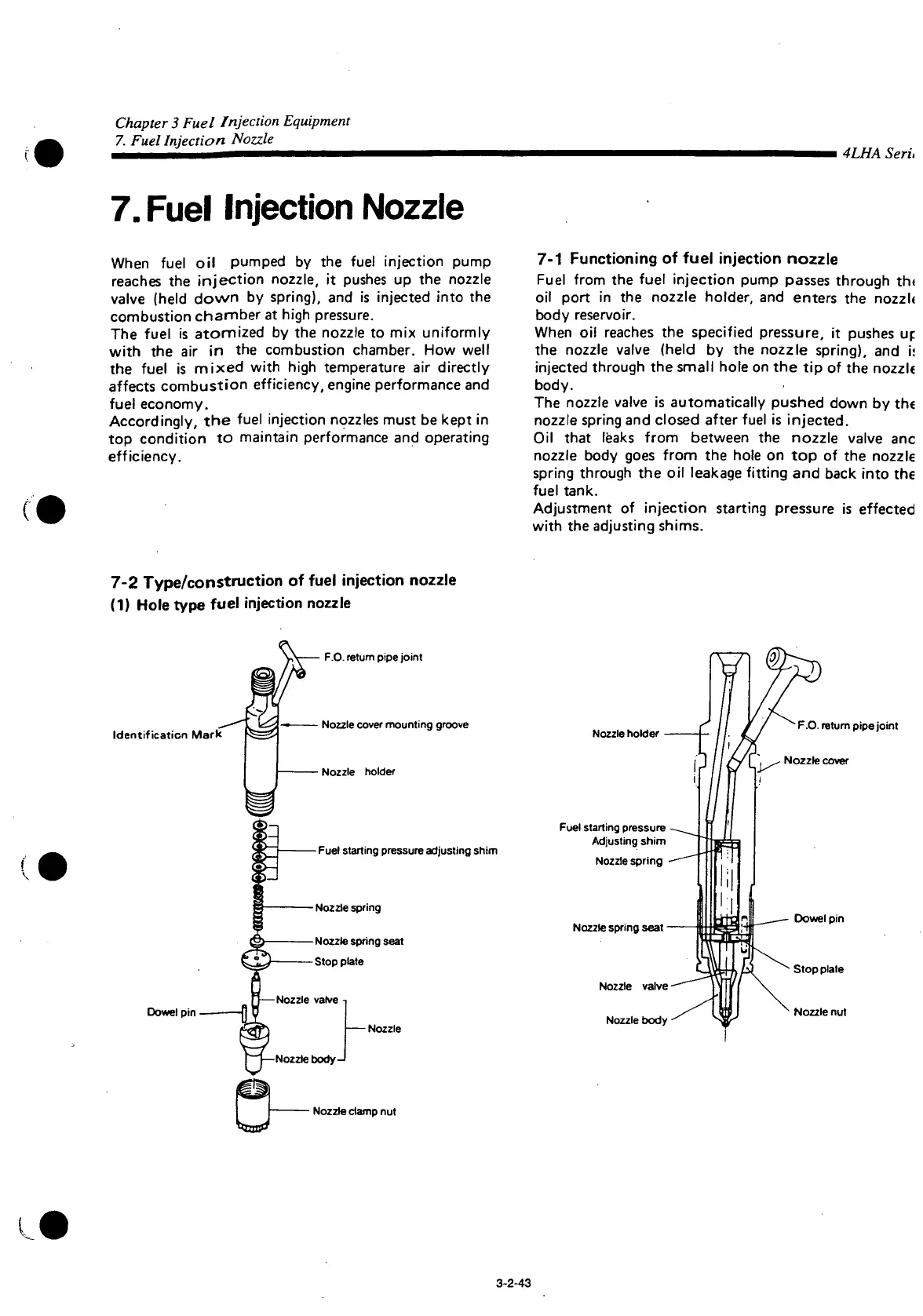

7-2 Type/construction of

fuel

injection

nozzle

(1)

Hole

type

fuel

injection

nozzle

Identification Mark

F.O.

return pipe

joint

Dowel

pin -

•

Nozzle

cover mounting groove

•Nozzle

holder

-

Fuel

starting

pressure

adjusting shim

Nozzle

spring

Nozzle

spring seat

Stop

plate

Nozzle

valve

Nozzle

body-I

-

Nozzle

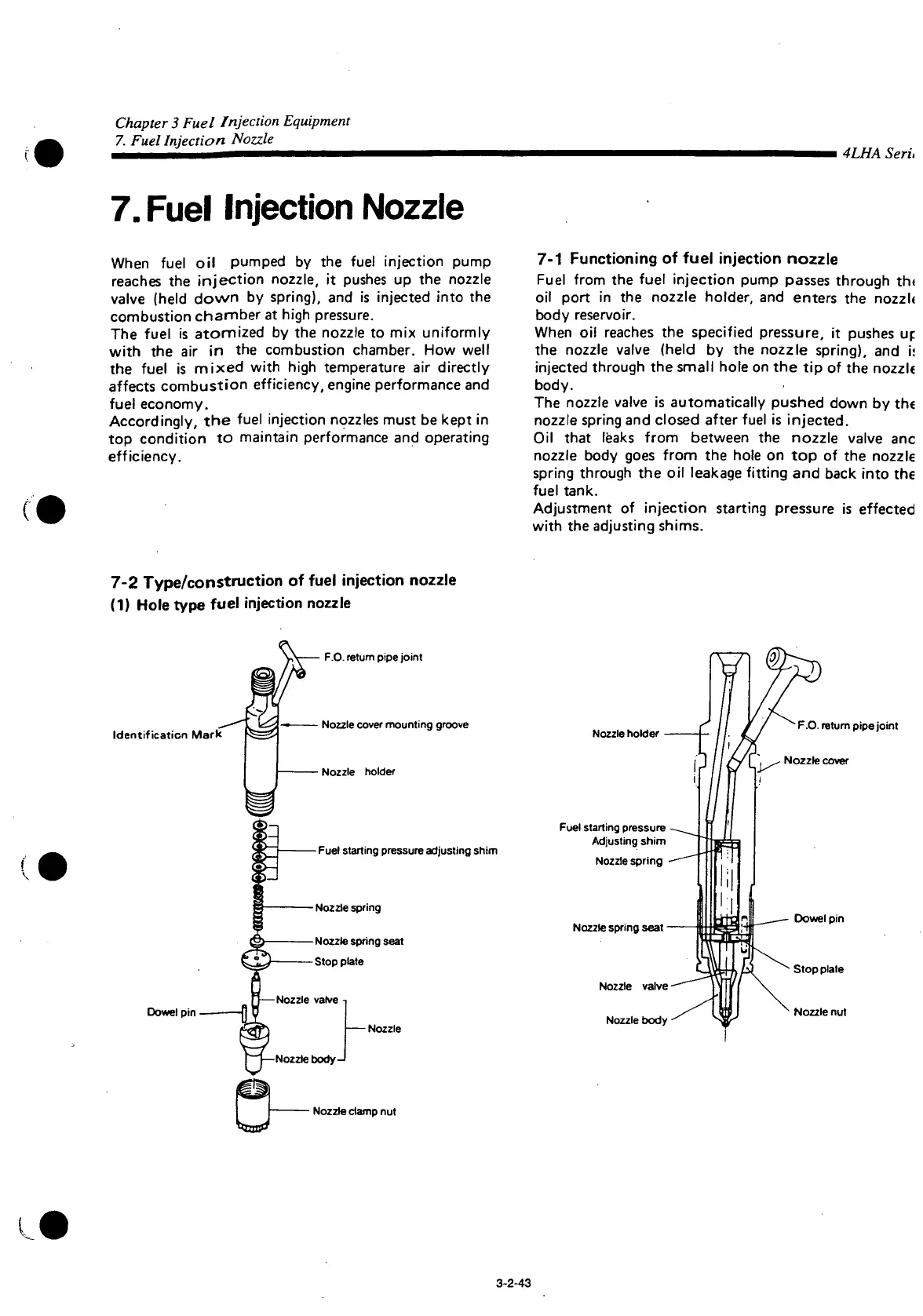

Nozzle

holder

Fuel

starting pressure

Adjusting shim

Nozzle

spring

Nozzle

spring seat

Nozzle

valve

Nozzle

body

F.O.

return pipe

joint

Nozzle

cover

Dowel

pin

Stop

plate

Nozzle

nut

-

Nozzle

damp nut

3-2-43

Loading...

Loading...