Chapter

3

Fuel Injection Equipment

5. Automatic Advancing Timer

i 4LHA Series

5.

Automatic

Advancing

Timer

5-1

Timer

construction

The

faster the engine

speed,

the larger the crank angle

is

during ignition delay. This results in a delay in

ignition

time

and thus a decrease in engine

output.

When

an engine is used

from

low to high

speed,

the

injection

timing

must be changed according to engine

speed

to maintain it at the optimum timing.

The

automatic timer uses centrifugal force to auto-

matically adjust injection timing.

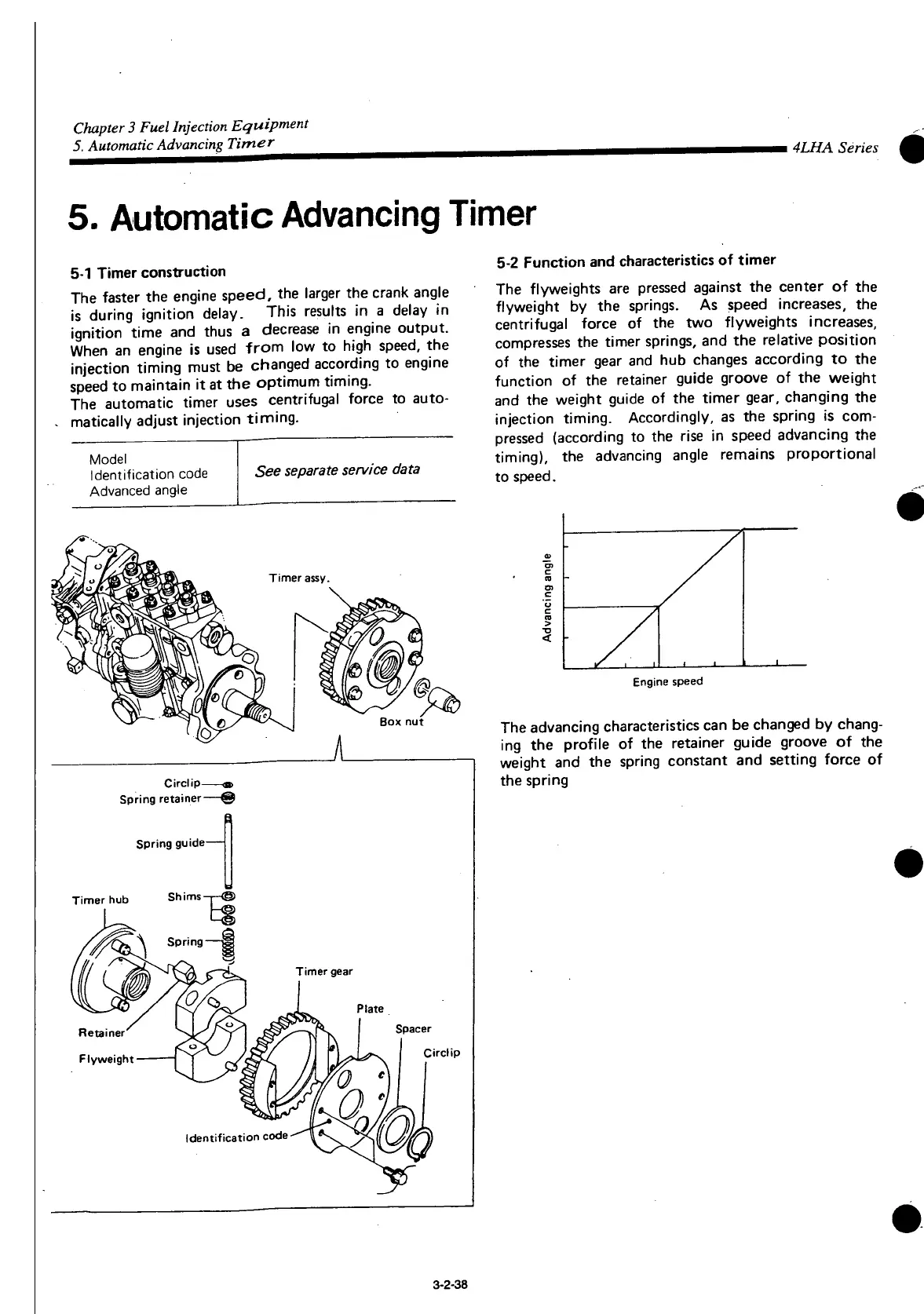

Model

Identification

code

Advanced

angle

See separate service data

Timer

assy.

Circlip-

Spring

retainer—©

Spring

guide

Timer hub Shims

Retainer

Flyweight

Identification

code

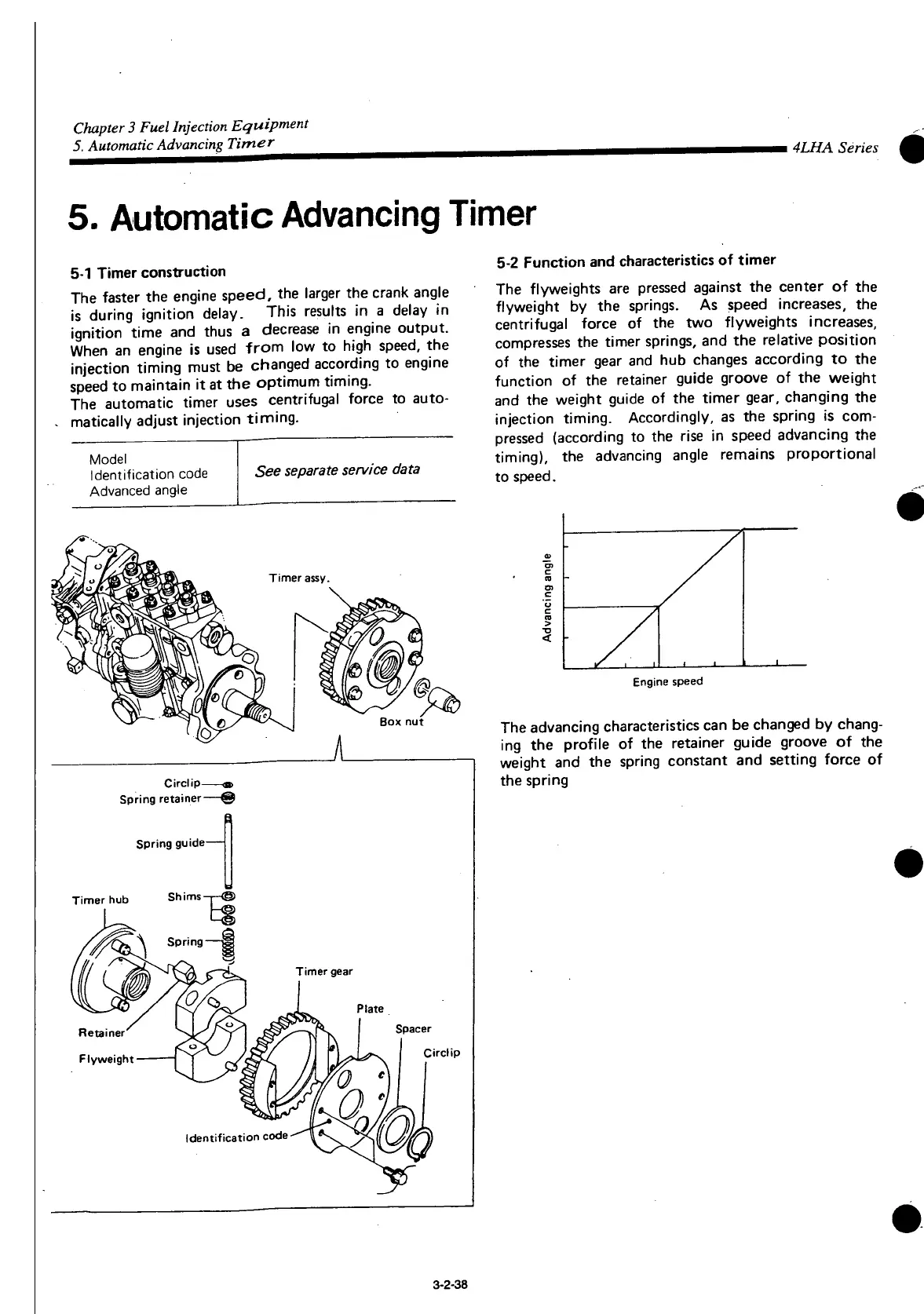

5-2 Function and characteristics of timer

The

flyweights are pressed against the center of the

flyweight

by the springs. As speed increases, the

centrifugal force of the two flyweights increases,

compresses

the timer springs, and the relative position

of the timer gear and hub changes according to the

function of the retainer guide groove of the weight

and

the weight guide of the timer gear, changing the

injection timing. Accordingly, as the spring is com-

pressed

(according to the rise in speed advancing the

timing), the advancing angle remains proportional

to

speed.

Engine

speed

The

advancing characteristics can be changed by chang-

ing the profile of the retainer guide groove of the

weight and the spring constant and setting force of

the spring

3-2-38

Loading...

Loading...