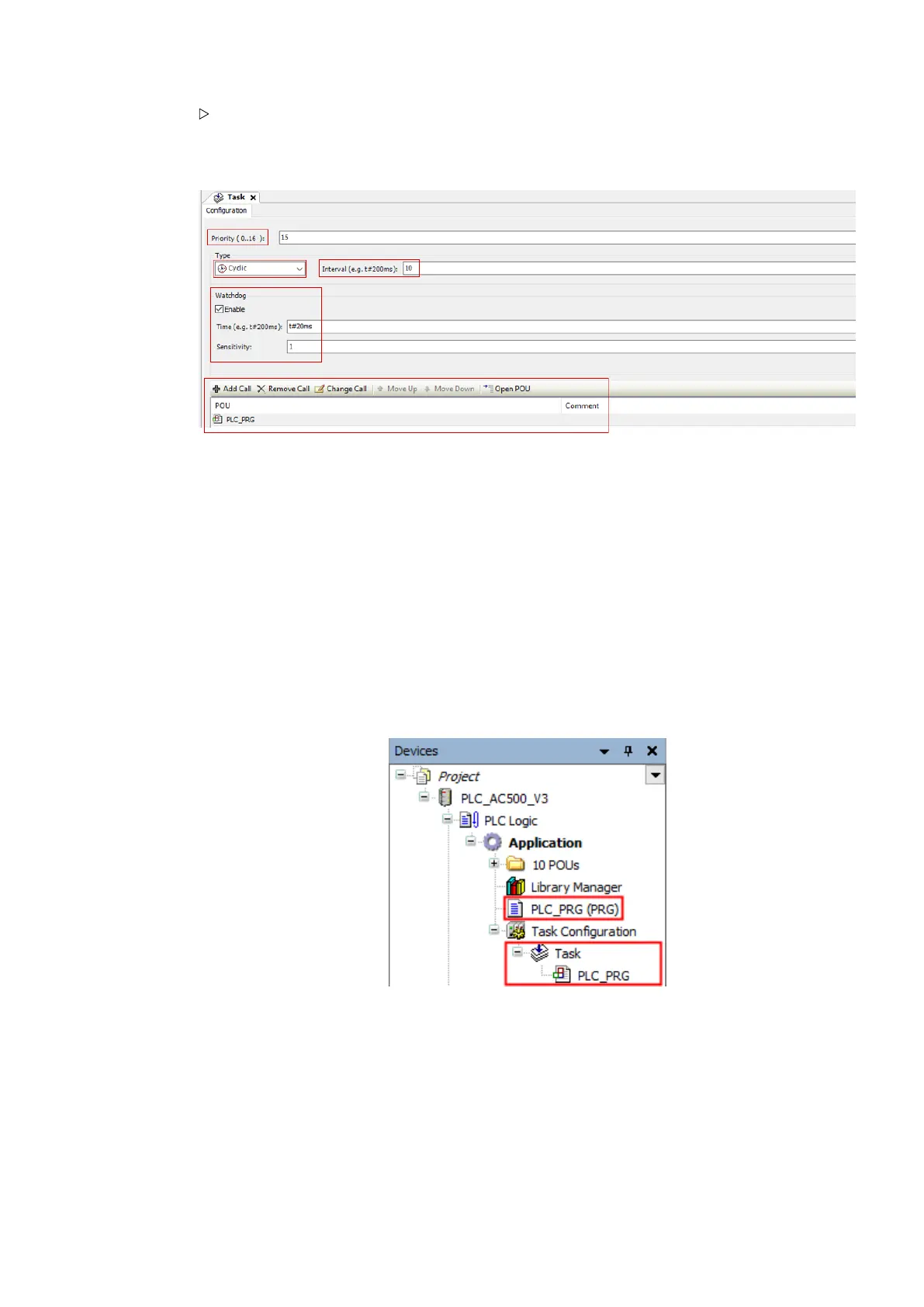

Double-click “Task” in the device tree.

ð

A tab opens in the editor view.

For this project you will use only one cyclic task. Keep the default settings for the task.

Priority This is how the CPU prioritizes the task, when more than one task is defined. Priority

0...15 = realtime tasks, priority 16 = non-realtime task.

Type In the CPU you can run tasks dependent on the demands of the process

Interval For cyclic tasks you can set the cyclical execution time. It is usually set in millisec-

onds with IEC time syntax

Watchdog To keep track of the time it takes to complete the task

Calls You can call in one or more program POUs in one single task

5.4.4.2 Main program PLC_PRG

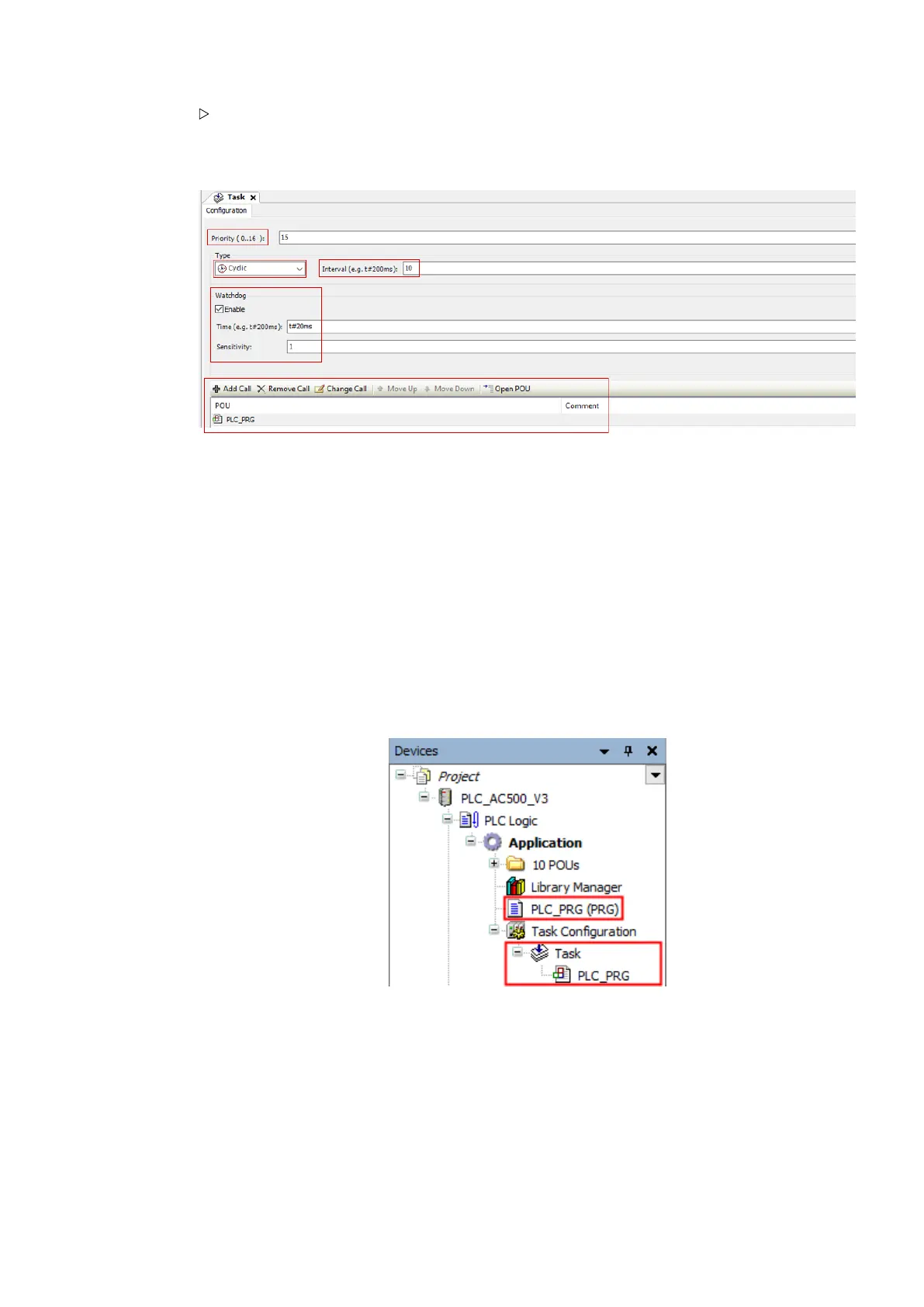

In the default task configuration, there is one call of a POU (program organization unit) i.e.

"PLC_PRG".

In your project the "PLC_PRG" will become a main program containing calls to other programs

(POUs) which you will create one by one.

The PLC_PRG POU has been defined by default in ST (structured text) editor. Keep this setting

because of good visibility of the instructions at a glance and good handling for troubleshooting.

To optimize the project readability, you will work with the previously created folder "10 POUs"

and add the created subroutines (POUs) to this folder. The subroutines will be created in FBD

(function block diagram) editor.

Example project > Programming and compiling

2021/06/293ADR010635, 2, en_US30

Loading...

Loading...