10 AO2000-LS25 LASER ANALYZERS | OI/AO2000-LS25-EN REV. D

… 2 Use in potentially explosive atmospheres in accordance with ATEX and IECEx

… Use in ATEX / IECEx Zone 1

Installing the pressurized enclosure

Purge parameters for pressurized enclosure

The purging and monitoring unit must guarantee the following

purge parameters.

12

12

11

48

0.8

4

20

20

Table 3: Ex “p” specifications

Purge air properties for pressurized enclosure

Value/Description

Class 533, in accordance with

See Table 3: Ex “p” specifications

Table 4: Purge air characteristics

* in accordance with EN 60079-2 (pressurized enclosure, Ex “p”)

Installation

Damage to the optical components

Damage to the optical components due to contaminated

purge gas.

• The purge gas must meet the quality requirements in

accordance with Table 4 on page 10.

Note

• The gas analyzer meets Ex approval only with a suitably

approved purging and monitoring unit for the pressurized

enclosure.

• The components of the pressurized enclosure are not

included in the standard delivery scope of the device, but can

optionally be supplied by ABB.

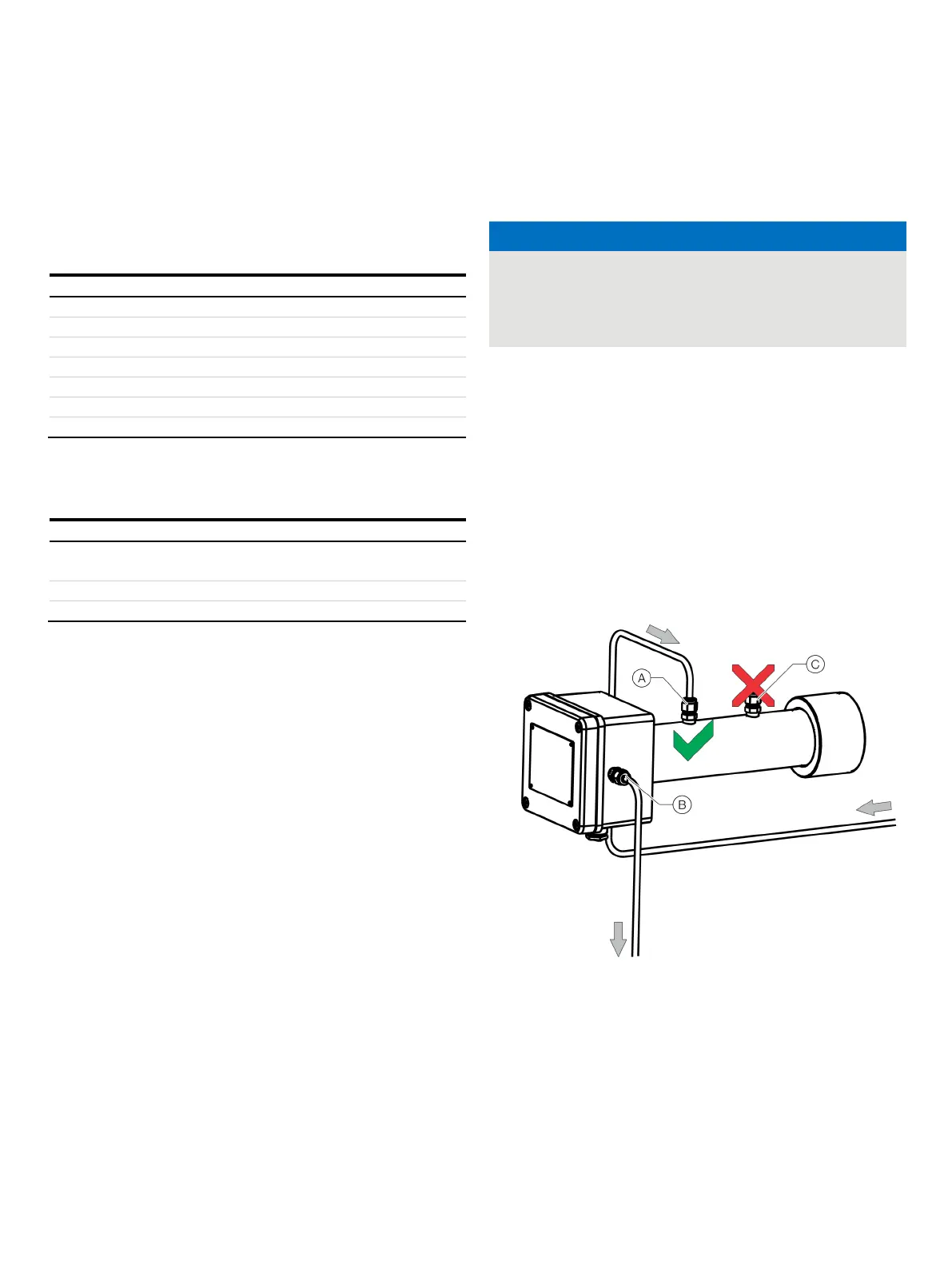

The installation of the pressurized enclosure must be performed

according to the schematic diagram in Figure 1 on page 7.

• Metal pipes with a 6 mm outside diameter are used as purge

gas lines and are connected to the corresponding Swagelok®

fittings on the transmitter and receiver unit.

Purge gas inlet from the transmitter unit

Purge gas inlet to the purging and monitoring unit

Do not use.

Figure 2: Purge gas connection to the receiver unit (air as purge gas)

Loading...

Loading...