78 AO2000-LS25 LASER ANALYZERS | OI/AO2000-LS25-EN REV. D

… 13 Maintenance

… Calibration of the device

Performing the calibration

Risk of injury due to process conditions.

The process conditions, for example high pressures and

temperatures, toxic and aggressive measuring media, can

give rise to hazards when working on the device.

• Before working on the device, make sure that the process

conditions do not pose any hazards.

• Shut off process connections and seal them with gas-tight

end caps to prevent the measuring medium escaping.

• Depressurize and empty the device / piping, allow to cool

and purge if necessary.

• If necessary, wear suited personal protective equipment

when working on the device.

Risk of suffocation

Risk of suffocation due to escaping purging gas when using

inert purging gases e.g. nitrogen (N

2

).

• Before opening the housing or flanged connections,

switch off the housing purging.

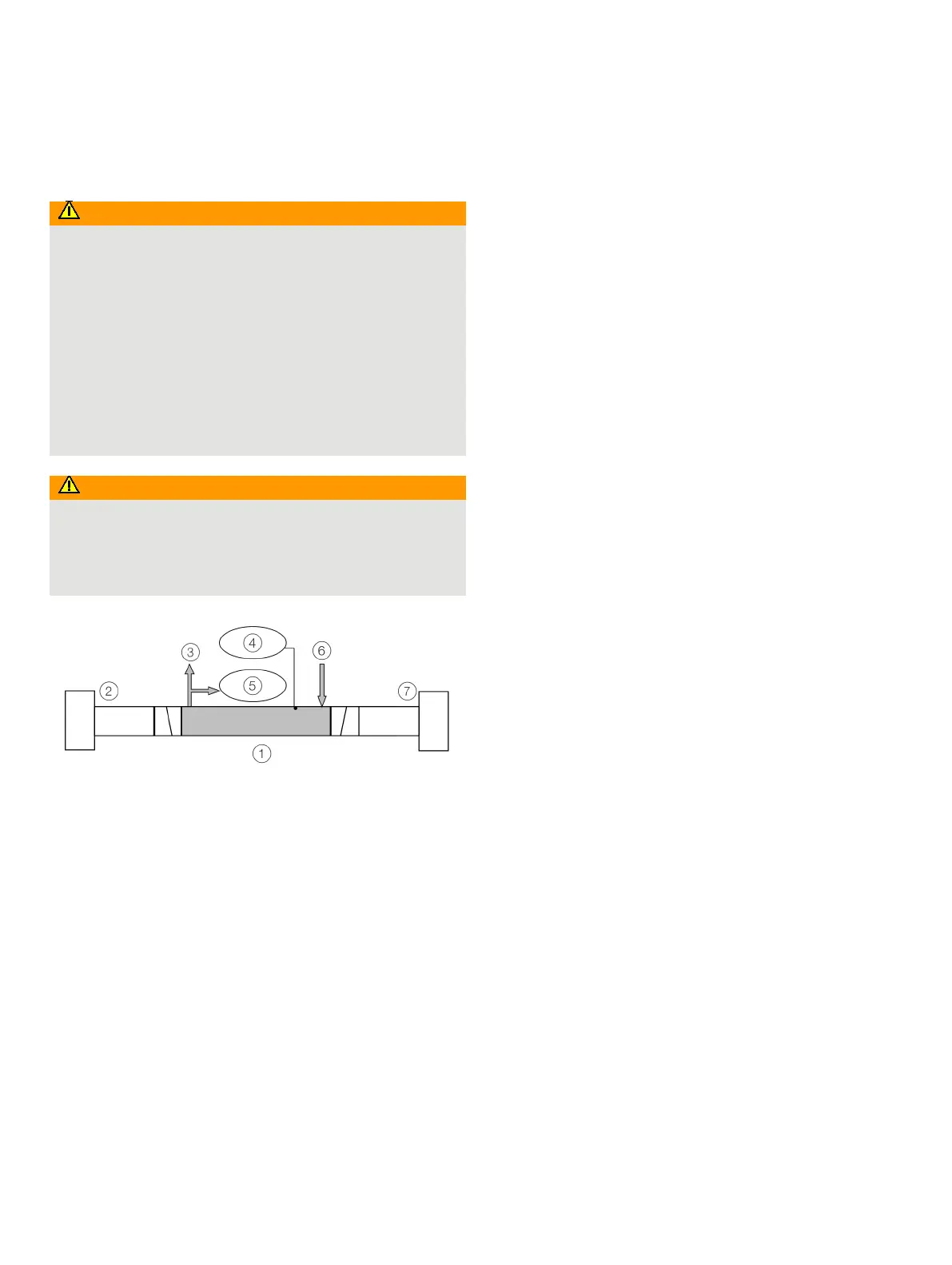

Calibration cell

Receiver unit

Gas outlet

Temperature sensor

Pressure sensor

Gas inlet

Transmitter unit

Figure 47: Calibration set

Perform the following steps to verify and calibrate:

1. Remove the transmitter and receiver units at the

measuring point.

2. Install the transmitter and receiver units on the test cell,

see Figure 47.

– Check the calibration set for leak tightness.e.g. by

testing with slight overpressure.

3. Connect the calibration cell temperature and pressure

sensors to the AO2000-LS25, see Connecting analog

inputs (option) on page 45.

4. Switch on the device, the device must be operational for

at least 1 hour before performing the verification and/or

calibration.

5. Start the service program, see Software start-up on

page 52.

6. Make sure that the measurement configuration

parameters are set correctly, see Measurement

configuration <Measurement configuration> on page 57.

– The flange length or concentration should be set to

zero.

– Check that the manually set temperature and

pressure are correct, or that the PLC inputs for the

gas temperature and pressure are correct.

7. Pressurize the cell with the calibration gas and set a

constant flow rate of 5 to 7 l/min.

– Wait until the system reaches stable levels.

8. Check if the reading is in agreement with the

concentration of the certified gas.

– Perform a PROPORTIONAL or GLOBAL calibration if

necessary, see Calibrating the device <Calibrate

instrument> on page 63 and PROPORTIONAL and

GLOBAL calibration on page 79.

9. Save the device settings to a file, see File download /

upload <File download / upload> on page 65.

10. Adjust the optical path parameters, pressure and

temperature again according to the measuring point

process parameters, see Measurement configuration

<Measurement configuration> on page 57.

11. Reinstall and commission the transmitter and receiver

units at the measuring point.

Loading...

Loading...