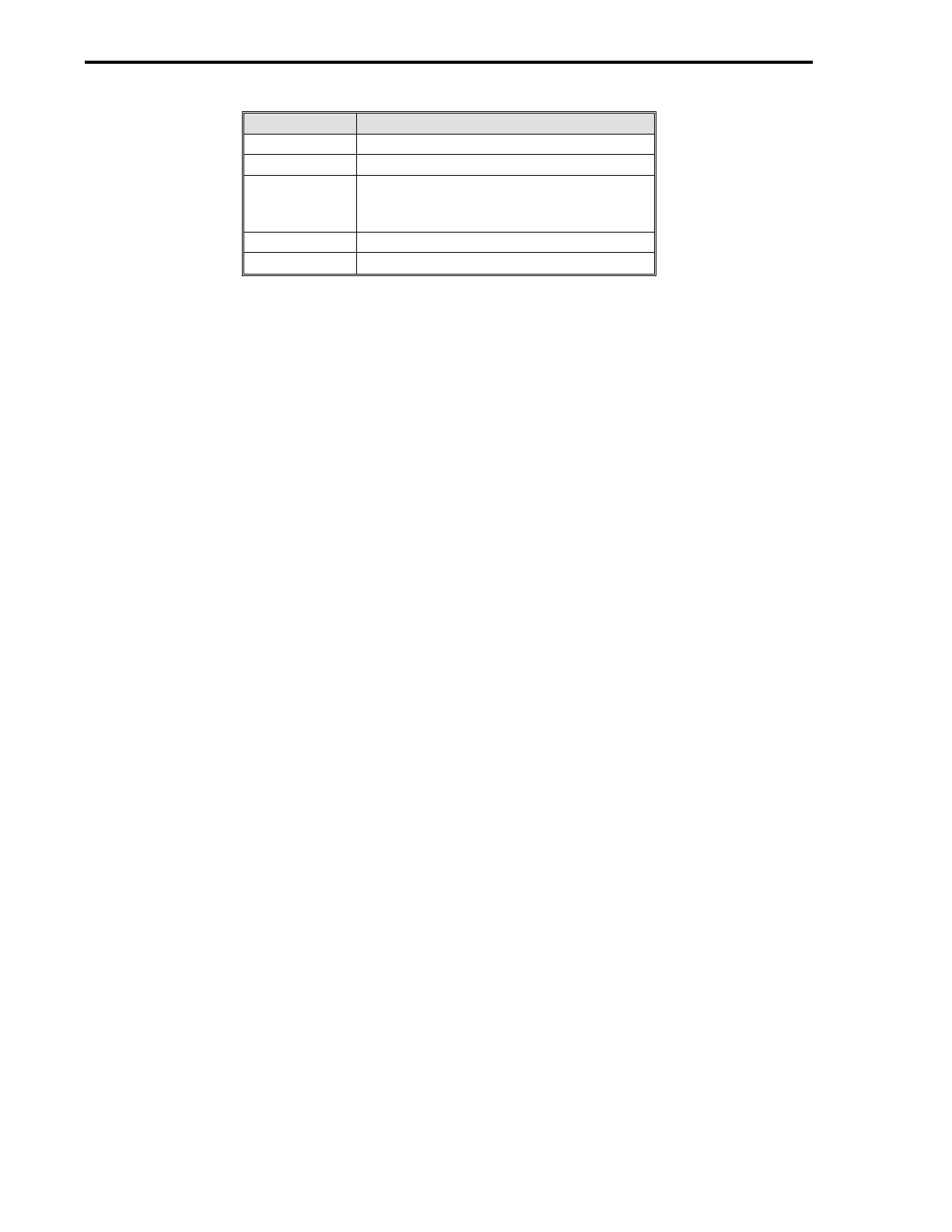

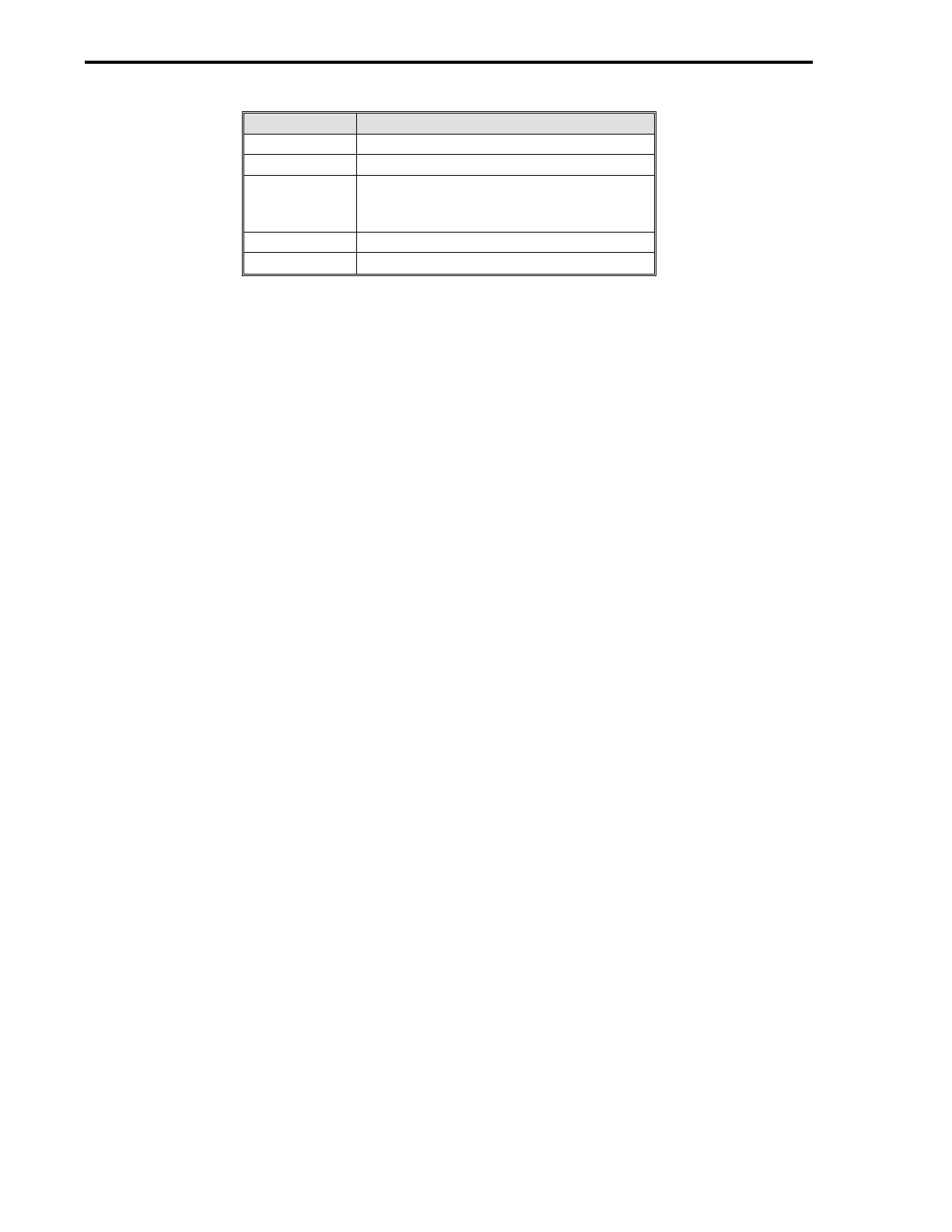

Data Type Data Format

B Are three digit characters 000-255.

L Is a one digit character 0 or 1.

C & H

Are ten digit characters including digits,

decimal point and sign (when

negative). Zero = 0.0.

A Are ten characters or less.

F Are five characters or less.

Pressing

ENTER

after pressing

D

automatically recalls the last datapoint number that was accessed.

Pressing

N

after pressing

D

causes the next datapoint of the same data type to be displayed. (The

NEXT

command

N

only works with index numbers below 256.)

3.13.1.3 ALTERING A CONTROLLER DATAPOINT

To modify a value or enter a new value press

P

and the datapoint number followed by

ENTER

. Then

press the keys corresponding to the value to be assigned followed by

ENTER

.

For example, to change AI0 Units (A298) from PERCENT to gallons per minute (GPM):

P A298 <ENTER> GPM <ENTER>

Values entered with the

PUT

command

P

must be formatted as follows:

In general, all modification inputs are limited to the first ten characters of the field.

For B type datapoints, the value entered must be between 0 and 255.

For L type datapoints, the value must be 1 or 0.

All responses are completed by pressing

ENTER

.

Pressing

ENTER

after pressing

P

automatically recalls the last database parameter.

Pressing

N

after pressing

P

causes the next datapoint of the same type to be displayed. (The

NEXT

command

N

only works with index numbers below 256.)

3.13.1.4 SETTING OR CHANGING A CONTROLLER PASSWORD KEY

As a security feature, the controller can be configured with a password key that is required to access

the Engineer Mode configuration function. The password key can be set by the Hand Held Config-

urer, or any of the personal computer application packages (53HC3300 or 53MT6000). It can also be

set from a SUPERVISOR-PC, but not with the controller faceplate push buttons. A password key is

a special data type (

Q1

) that is displayed or configured just like any other data type using the Hand

Held Configurer. The value assigned to a password key must be an ASCII numeric string up to 10

characters because only numbers (0-9) are permitted as

KEY?

input characters by the controller. To

remove a password key completely, press

CTRL

0

(hold

CTRL

and press

zero

, then ENTER.

53MC5000 Process Control Station

3-24

Loading...

Loading...