3.3 SmarTac board characteristics

3.3.1 Interaction with the welding equipment and weldment

SmarTac board

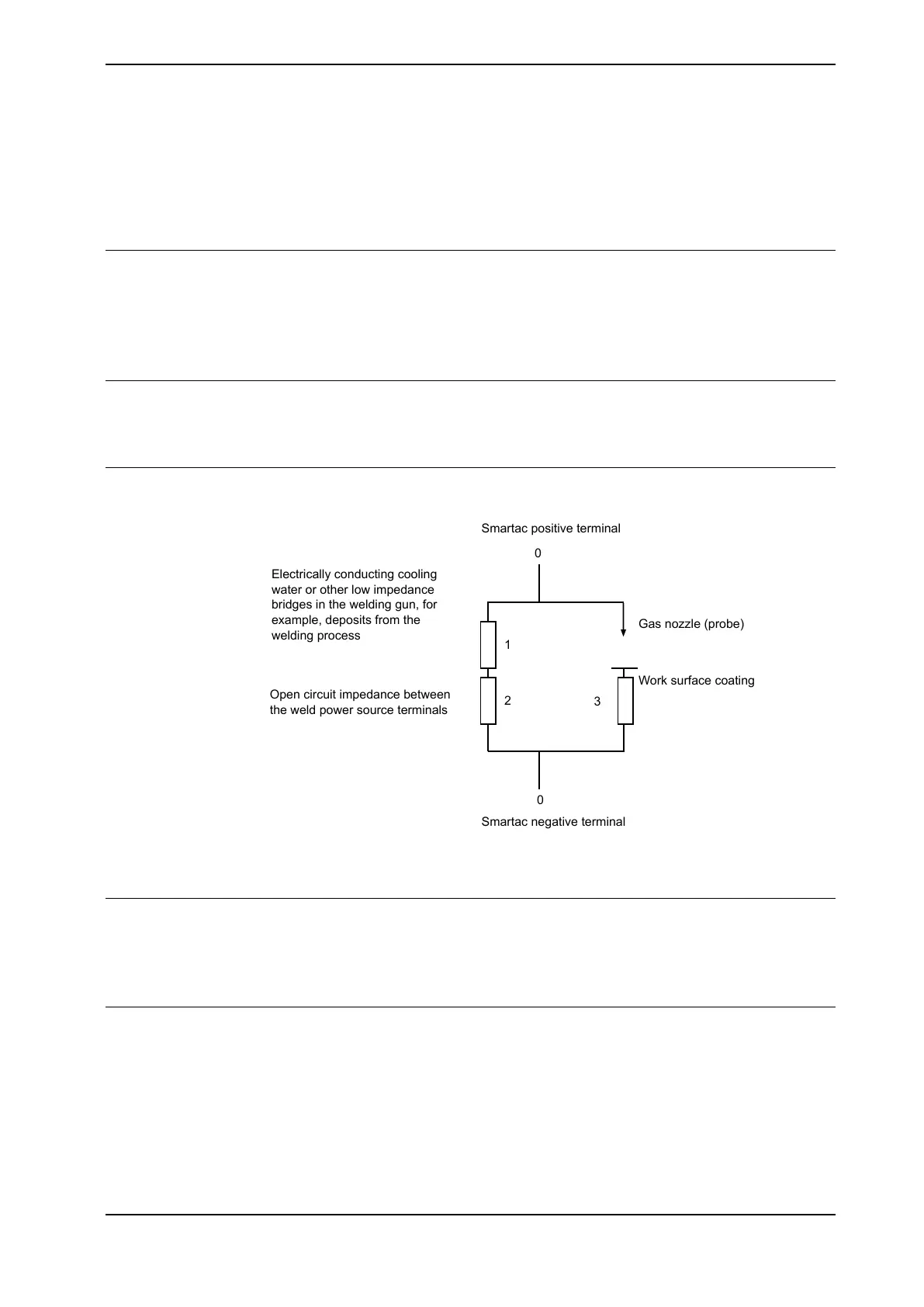

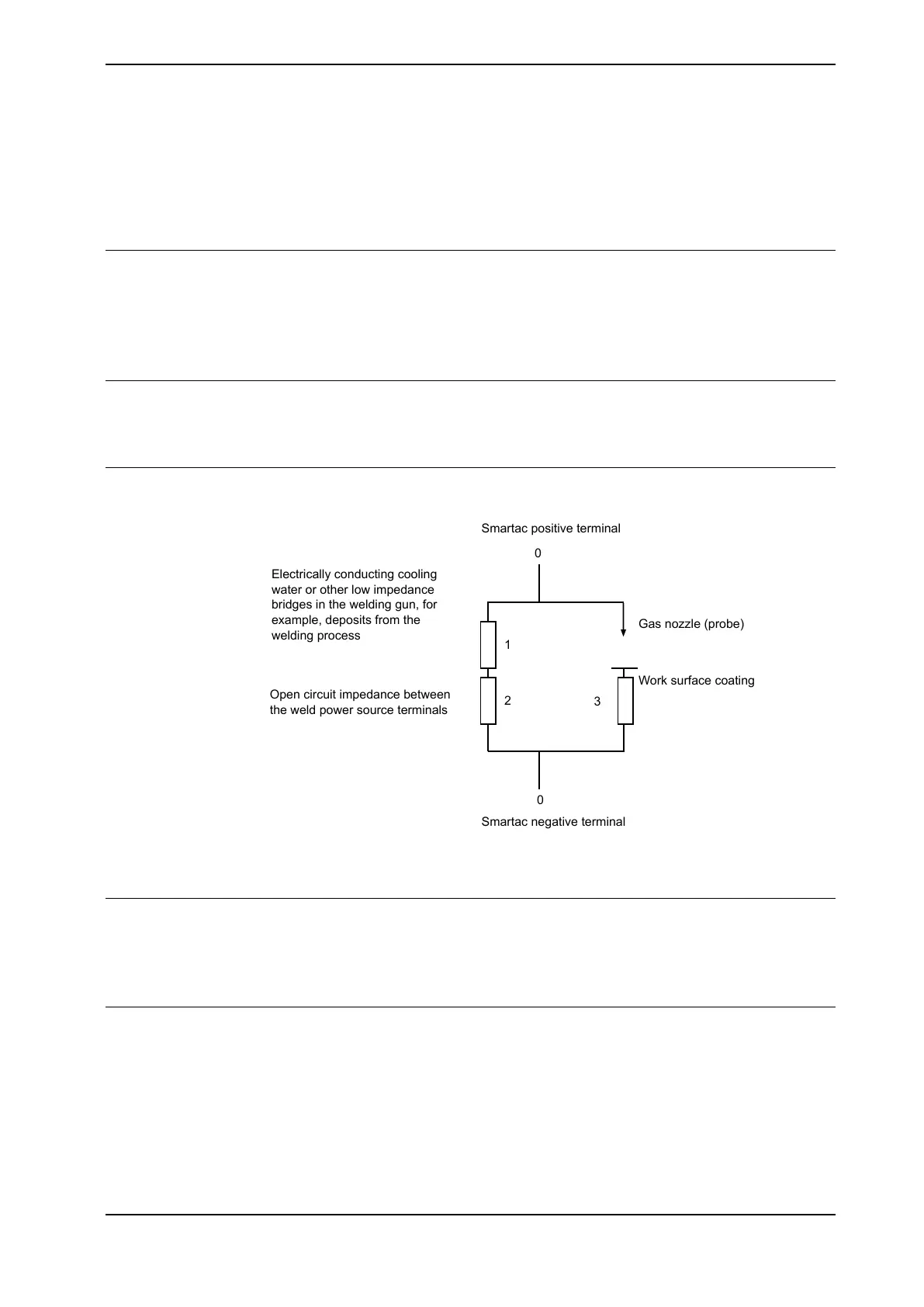

The SmarTac board (alone) is capable of generating a stop signal from

high-resistance surfaces with up to 1 Mom contact resistance. In real applications,

however, the SmarTac sensing circuitry is normally loaded from the surrounding

welding equipment. The electric equivalent diagram below explains the situation.

Sensitivity

Maximum sensitivity will only be obtained when using a separate, highly insulated

probe (not supplied).

Electric equivalent diagram

1

2

3

0

0

Smartac positive terminal

Smartac negative terminal

Gas nozzle (probe)

Work surface coating

Electrically conducting cooling

water or other low impedance

bridges in the welding gun, for

example, deposits from the

welding process

Open circuit impedance between

the weld power source terminals

xx1400001476

Convection-cooled welding gun

SmarTac used with a convection-cooled (air cooled) welding gun will loose some

sensitivity due to losses through the weld equipment. In the circuit above, this loss

is described by resistor #2.

Positive lead secondary contact

In systems with a positive lead secondary contact, the loss through the weld

equipment is eliminated.

Continues on next page

Application manual - SmarTac 27

3HAC024845-001 Revision: A

© Copyright 2004-2016 ABB. All rights reserved.

3 Application guide

3.3.1 Interaction with the welding equipment and weldment

Loading...

Loading...