4.7 Exercise 5: using SmarTac with work object manipulation

4.7.1 Introduction

Weld paths

Sometimes using multiple displacement frames can not provide an easy way of

determining a weld seam's location. In exercise 4 we proved that a simple weld

path could be moved in translation and rotation using two displacement frames;

one for the start and one for the end of the weld path. If the weld were not

continuous, that is a stitch weld, this would not work. There is no displacement

information about the intermediate weld points.

Work object

In some cases it is necessary to determine how the whole part has moved in

translation and rotation. The best way to do this is to use a work object to describe

where the part is in relation to the world frame. Based on search information, the

object frame of a work object can be moved in translation and rotation. If the weld

sequence in written in this work object, the points in the sequence will move with

changes to the work object.

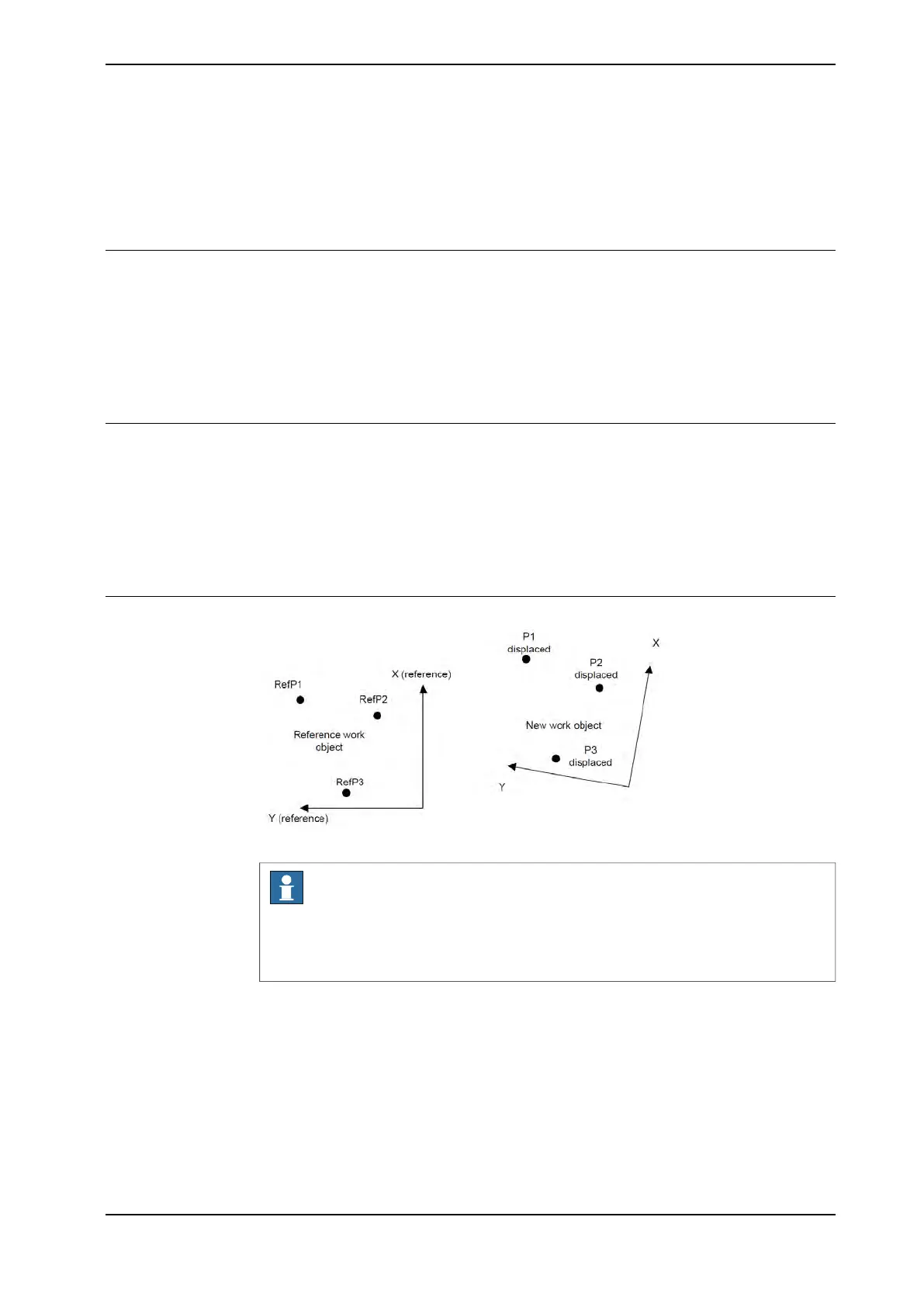

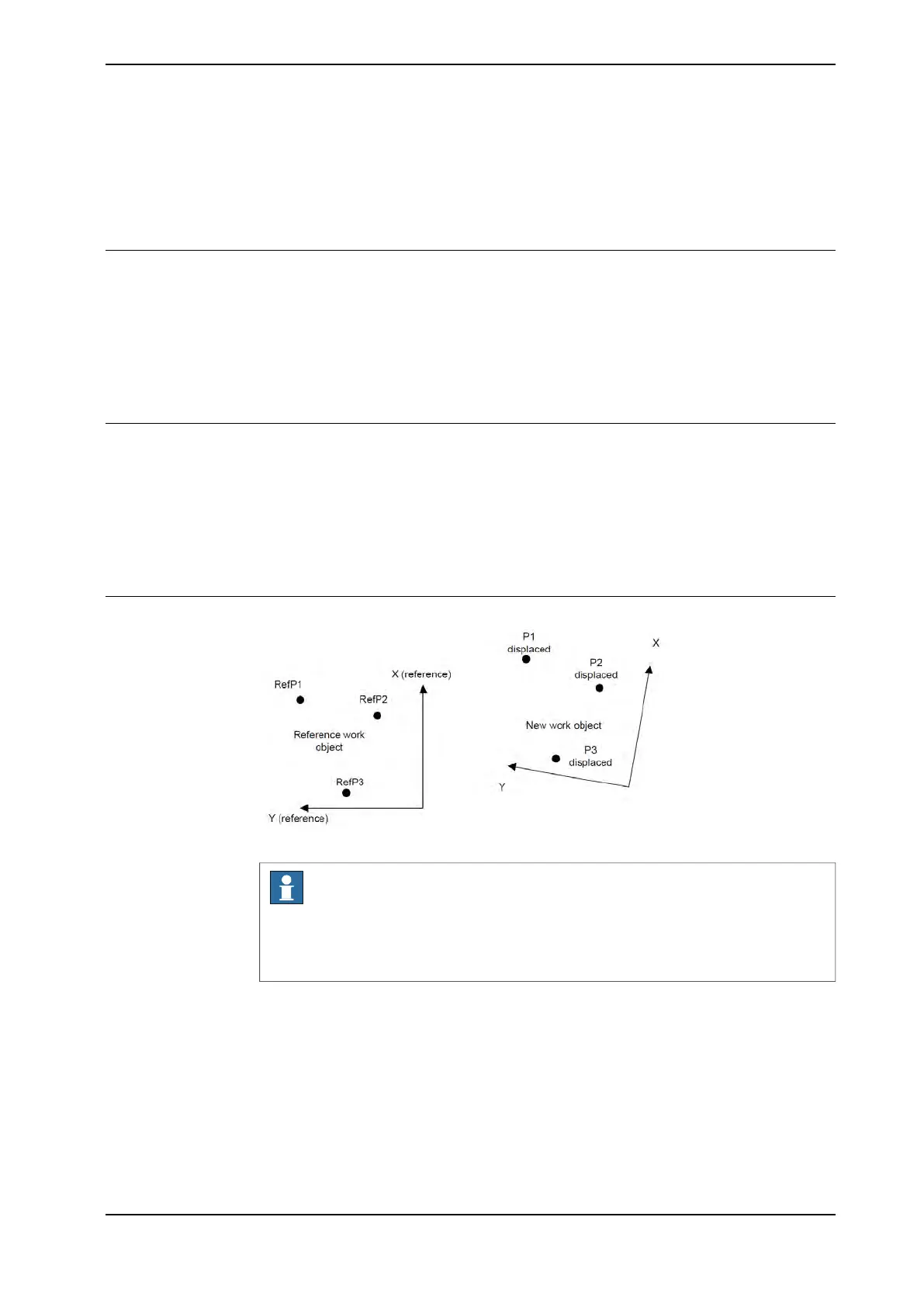

Example 1

xx1400001508

Note

An important benefit to this technique is that searching and program

displacements can still be used for features on the part after the part program

has been rotated in the work object.

Continues on next page

Application manual - SmarTac 59

3HAC024845-001 Revision: A

© Copyright 2004-2016 ABB. All rights reserved.

4 User's guide

4.7.1 Introduction

Loading...

Loading...