182 Rockwell Automation Publication 750-IN001P-EN-P - April 2017

Chapter 4 Power Wiring

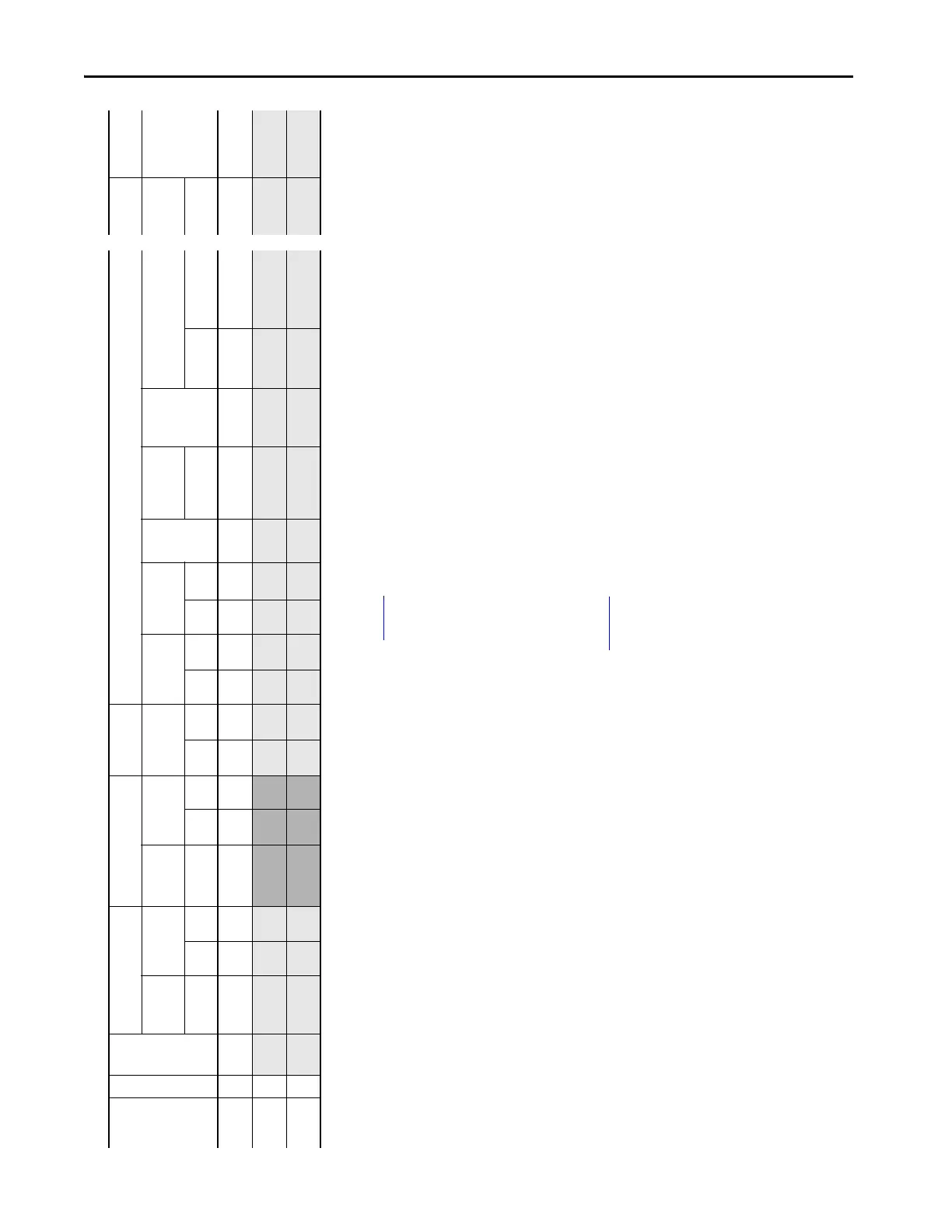

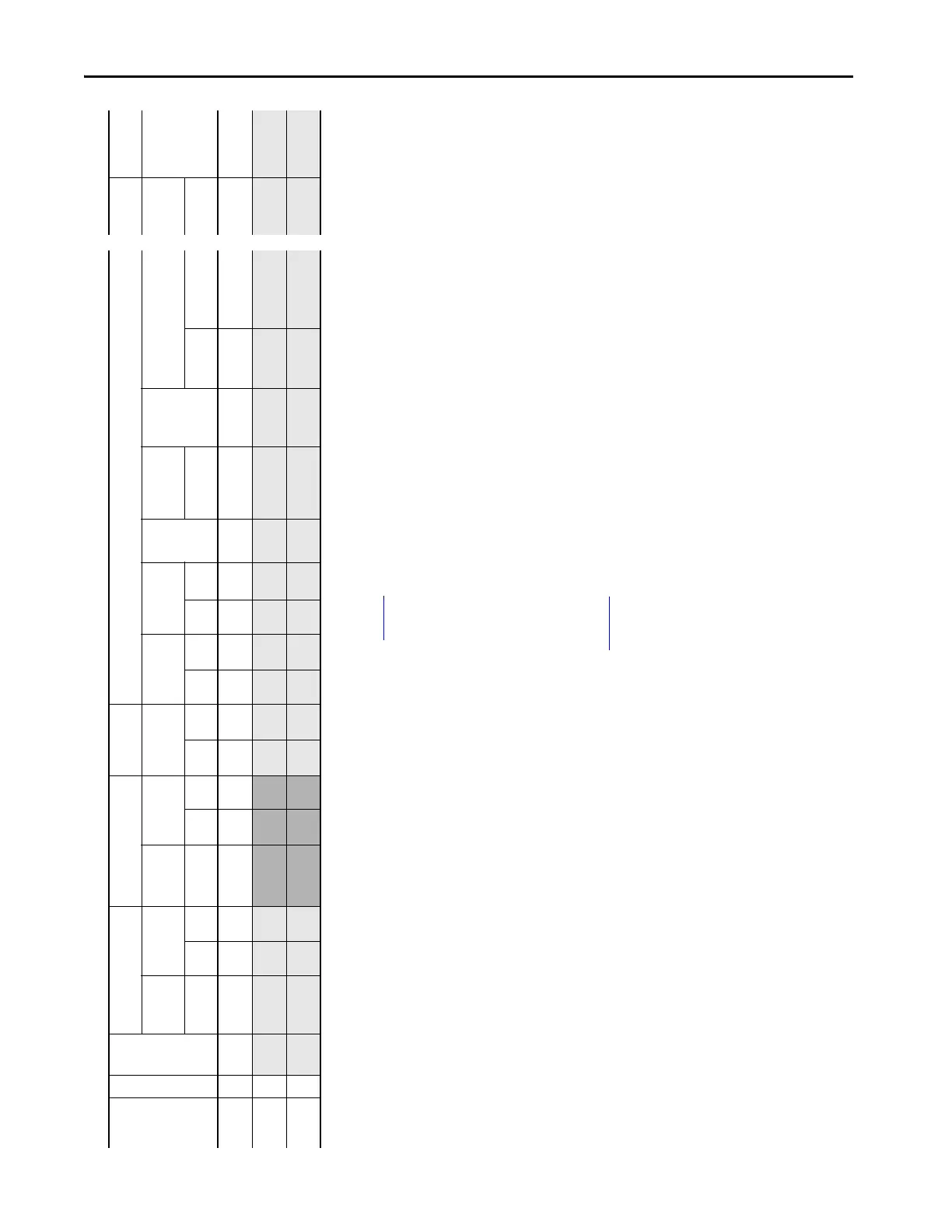

300 Hp 7 361 20x…D361 397.1 541.5 20x…D415 541.5 649.8 281.8 338.9 475 800 475 1000 1000 600 396.1 Bussman

170M6612

350 Hp 7

415 20x…D415 456.5 622.5 323.9 389.6 525 900 525 1200 1200 600 455.3 Bussman

170M6612

400 Hp 7

477 20x…D477 524.7 715.5 372.3 447.8 600 1000 600 1400 1400 600 523.3 Bussman

170M6613

(1) “Applied Rating” refers to the motor that will be connected to the drive. For example, a “D022” drive can be used in Normal Duty mode on a 15 Hp motor, or in Heavy-duty mode on a 10 Hp motor. A “D014” drive can be used in Heavy-duty mode on a 7.5 Hp motor with

the same ratings as a “D011.” The drive can be programmed for either mode. Wiring and fuses can be sized based on the programmed mode. For any given drive catalog number, Normal Duty mode provides higher continuous current but smaller overload current that is

compared to Heavy-duty mode. See parameter 306 [Duty Rating].

(2) Enclosure codes F, N, and R only. See Frame/Rating Cross-reference in PowerFlex 750-Series AC Drives Technical Data, publication 750-TD001

, for frame sizes of other enclosure types.

(3) This drive is the next larger frame size.

(4) Minimum protection device size is the lowest rated device that supplies maximum protection without nuisance tripping.

(5) Maximum protection device size is the highest rated device that supplies drive protection. For US NEC, minimum size is 125% of motor FLA. Ratings that are shown are maximum.

(6) Circuit Breaker – inverse time breaker. For US NEC, minimum size is 125% of motor FLA. Ratings that are shown are maximum.

(7) When using a circuit breaker or time-delay fuse with a drive installed in a ventilated enclosure, the enclosure volume must be greater than or equal to the minimum volume specified in this column. Application-specific thermal considerations can require a larger

enclosure.

(8) Recommended Motor circuit protector – Instantaneous trip circuit breaker. Set the trip setting to the input current of the drive and size for the continuous current of the system.

(9) For Bulletin 140M with adjustable current range, set the current trip to the minimum range that the device will not trip.

(10) Manual Self-Protected (Type E) Combination Motor Controller, UL Listed for 480Y/277V and 600Y/347V AC Input. Not UL Listed for use on 480V or 600V Delta/Delta, corner ground, or high-resistance ground systems.

(11) Bulletin 140M must be frame C (C2E), frame D (D8E), or frame F (F8E).

(12) Bulletin 140M must be frame D (D8E) or frame F (F8E).

(13) When using a Manual Self-Protected (Type E) Combination Motor Controller, the drive must be installed in a ventilated or non-ventilated enclosure with the minimum volume that is specified in this column. Application-specific thermal considerations may require a larger

enclosure.

(14) See Fuse Certification and Test Data in PowerFlex AC Drives in Common Bus Configurations Application Guidelines, publication DRIVES-AT002

, for fuse self-certification and test data for Bussmann 170M and JKS fuses recommended for the DC bus fusing.

Table 21 - 480 Volt AC and 650 Volt DC Input Protection Devices – Wall Mount Frames 1…7 (Continued)

Applied

Rating

(1)

Frame

(2)

Cont.

Output

Amps

Drive Sized For Normal Duty Drive Sized For Heavy Duty Input

Quantities

AC Input Protection Devices Input

Quantities

DC Input

Protection

(14)

Catalog

Number

Output

Overload Amps

Catalog

Number

Output

Overload Amps

Continuous AC

Input

Dual Element

Time Delay

Fuse

Non-Time Delay

Fuse

Circuit

Breaker

Max

Size

(6)

Circuit Breaker,

Dual Element

Time Delay Fuse

Motor

Circuit

Protector

(8)

140M Type E Combination Motor

Controller with Adjustable

Current Range

(9)

(10)

Continuous

DC Input

Non-Time

Delay Fuse

(x = F or G) 1 min 3 sec (x = F or G) 1 min 3 sec kVA Amps Min

(4)

Max

(5)

Min

(4)

Max

(5)

Min Enclosure

Volume (in.

3

)

(7)

Cat. No. Min Enclosure

Volume (in.

3

)

(13)

Amps

Loading...

Loading...