170 Rockwell Automation Publication 7000-UM202D-EN-P - May 2018

Chapter 3 Control Component Definition and Maintenance

Each OIB board also has input RX7 for a signal from a temperature feedback

board. The quantity and location of thermistor connections is dependent on

the drive configuration. Typically, there is one temperature sensor from the line

converter and one temperature sensor from the machine converter, each going

into the respective OIB board in the ‘A’ position. However, some drive

configurations only require one thermistor feedback connection. The

temperature feedback connection on OIBC is not implemented on the OIBB

and is never used. For more information, see the drawings supplied with your

drive. The alarm and trip set points for each of these signals are programmable

in software.

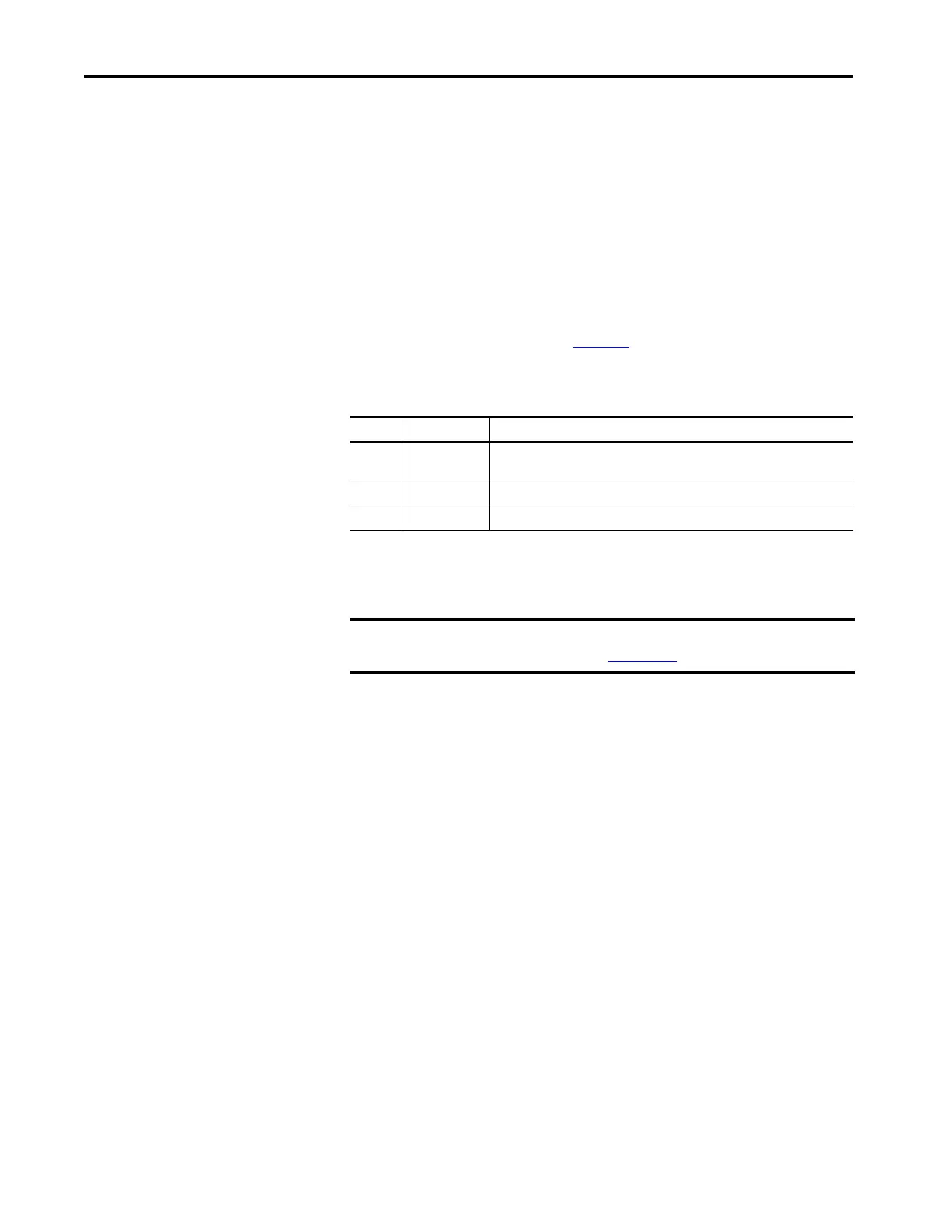

There are three LEDs on the OIB. Table 15

illustrates the status and

description for the LED states.

Replacing the Optical Interface Board

1. Isolate and lock out all power to the drive.

2. Mark the location and orientation of all the fiber optic cables. Use the

electrical drawing for reference.

3. Ground your static strap, and disconnect all of the connections. You may

need to remove the 60 core cable connectors on the Optical interface

base and the ground connection for access to the standoffs

4. Remove the OIB board from the OIBB. There are four standoffs that

snap into place on the OIB, and they need to be carefully handled when

disconnecting the boards. There is also the 28-pin connection between

the boards, and this connection should be handled carefully as you do

not want to bend the pins.

5. Install the new OIB on the OIBB. Ensure the standoffs snap into place.

6. Reconnect all fiber optic connections and verify the locations.

7. Apply low voltage power and complete gating, system, and medium

voltage tests to confirm board performance.

Table 15 - Color Explanation for OIB LEDs

LED Status Description

D1 Red – On Run – The OIB has received an enable signal. The drive control software is in control

of all gating.

D2 Yellow – On Ready – The OIB power supply is sufficient for proper operation.

D3 Green – On Power – The OIB has received a voltage signal greater than 2V.

IMPORTANT If the drive is equipped with the Safe Torque Off option, the drive will use

OIB2 boards. See publication 7000-UM203

to replace the OIB2 boards.

Loading...

Loading...