54 Rockwell Automation Publication 7000-UM202D-EN-P - May 2018

Chapter 2 Power Component Definition and Maintenance

5. Connect a low voltage single-phase test power, for instance 110V or

220V, across a phase and the neutral of the capacitor. Switch on the test

power and measure the test voltage and current drawn by the capacitor.

Repeat the test for all three phases and note down the test voltage and

current.

6. Calculate the capacitance from the measured values of test voltage and

current. For a good capacitor, the calculated capacitance value for each

of the three readings should be within ±15% of the capacitor nameplate

micro-Farad. If it is outside this range, the capacitor must be replaced.

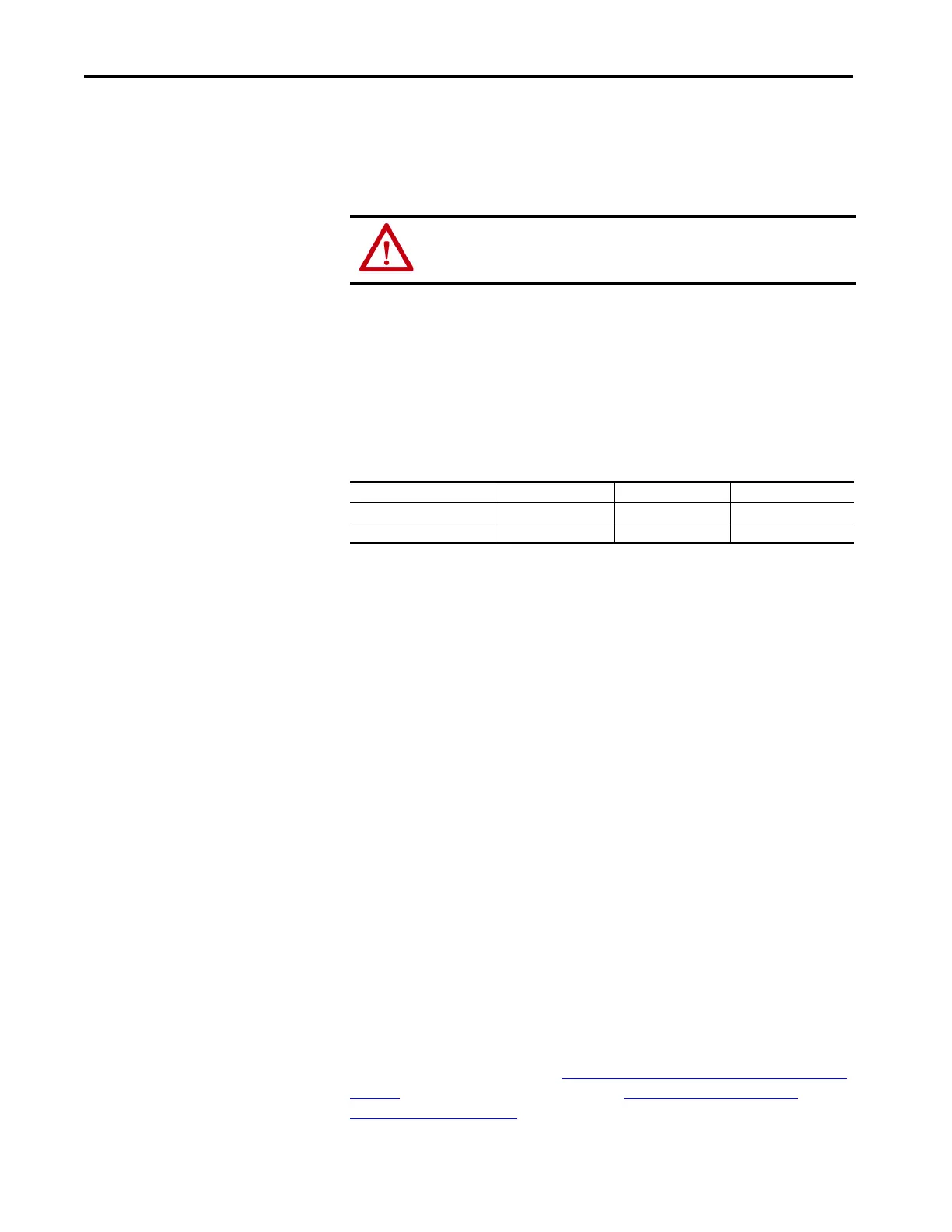

Suppose that a capacitor under test is rated at 400 kVAR, 6600V, 50 Hz,

29.2 F. Assume that you are using 200V, 50 Hz test power with the recorded

voltage, and current values for each test as shown in the table below.

Calculate the capacitance using the first reading. In this case:

Similarly, you can calculate the capacitance for the remaining two

measurements for L2-N and L3-N.

Converter Cabinet

Components

This section describes the converter cabinet components of your PowerFlex

7000 “B” Frame drive. This section also details a number of regular or recurring

maintenance tasks that will keep your drive in peak operating condition.

The converter cabinet contains three rectifier modules and three inverter

modules. Isolated gate driver power supplies (IGDPS) are available on the right

side sheet of the cabinet.

Thermal sensors are available on the top module of the inverter and rectifier.

The exact location depends on the drive configuration. These sensors connect

to temperature feedback boards that return signals to the drive control.

For control/cabling cabinets, see Control / Cabling Cabinet Components

on

page 29. For DC link and fan cabinets, see DC Link and Fan Cabinet

Components on page 115.

ATTENTION: The capacitor will charge during this test so take care to prevent

a shock or injury. When moving the test connections from one phase to the

next, wait five minutes minimum for the capacitor to discharge.

Phase - Neutral L1-N L2-N L3-N

Test voltage 200V 200V 200V

Measured current 1.87 A 1.866 A 1.861 A

V = 200V, I = 1.87 for L1-N

Xc = V/I = 200/1.87 = 106.95

C= 1/ (2

π F Xc)

C= 1/(2 x 3.14 x 50 x 106.95

C=29.7 F

Where:

F = frequency of the applied voltage.

Loading...

Loading...