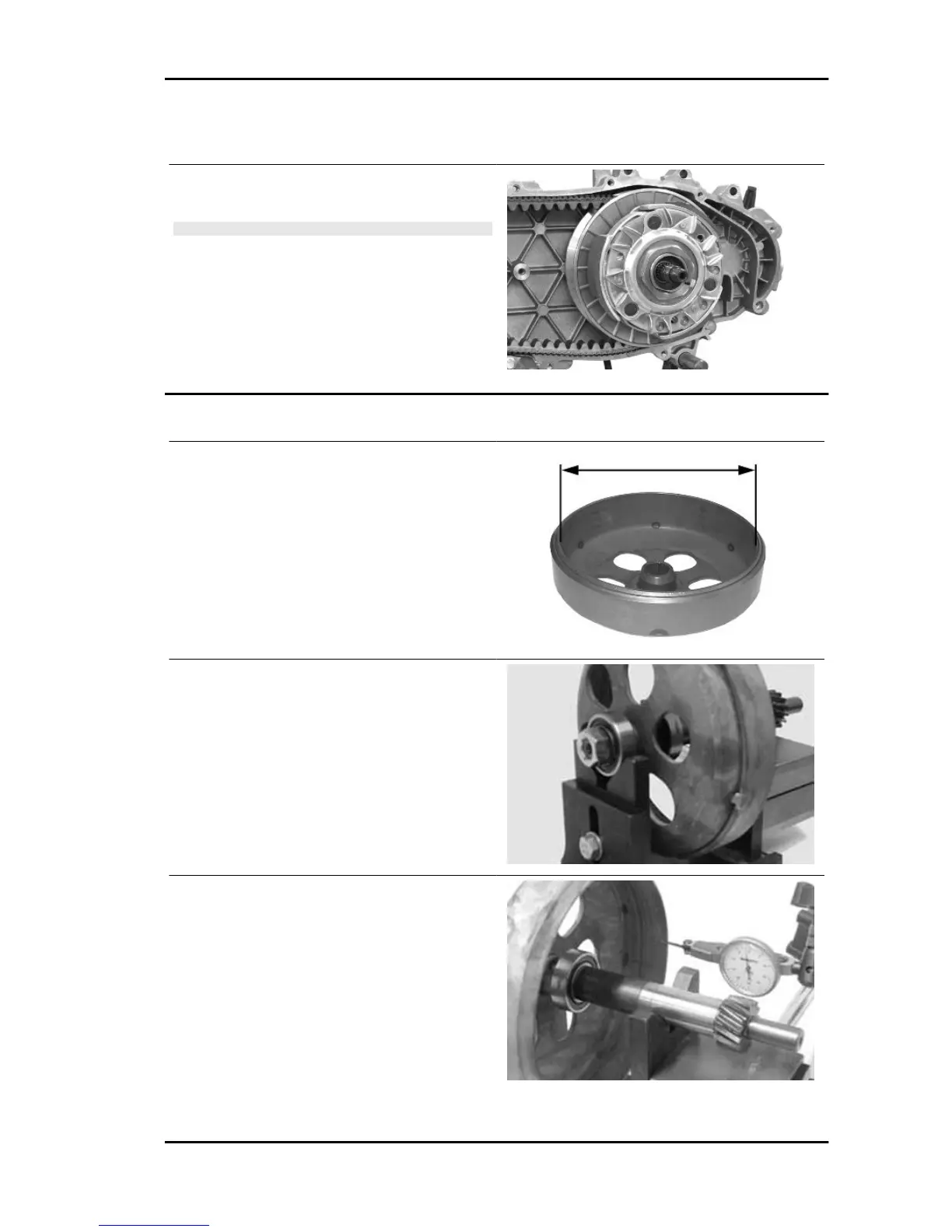

Removing the driven pulley

- Remove the clutch bell and the entire driven pul-

ley assembly.

NOTE

THE ASSEMBLY CAN ALSO BE REMOVED EVEN IF THE

DRIVING PULLEY IS MOUNTED.

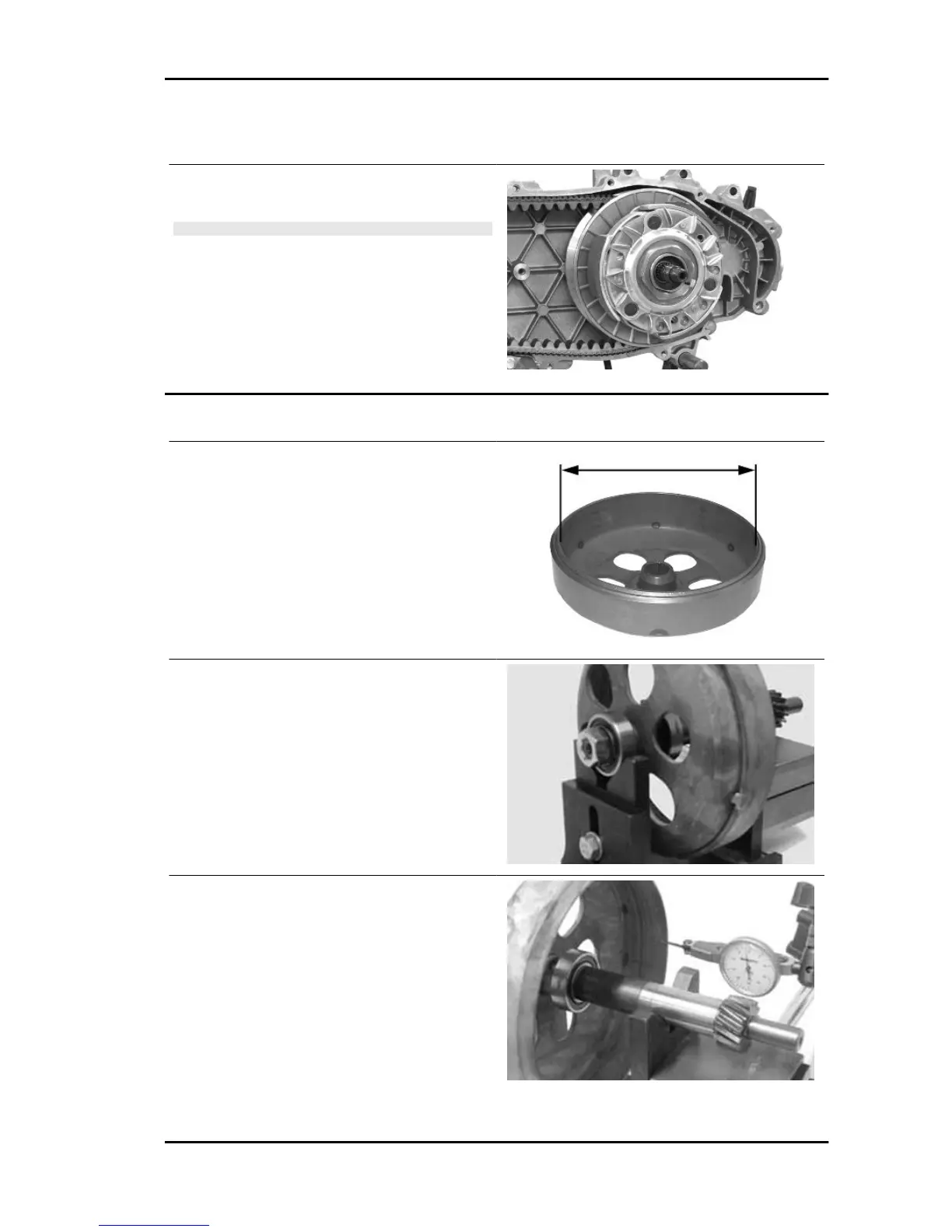

Inspecting the clutch drum

- Make sure that the clutch bell is not worn or dam-

aged.

- Measure the clutch bell inside diameter.

Characteristic

Max clutch bell value (300 cm³)

Ø 134.5 mm

Clutch bell standard value

Ø 134 ÷ 134.2 mm

Checking the bell working surface eccentricity

- Fit the bell on a driven pulley shaft with 2 bearings

(inside diameter: 15 and 17 mm).

- Lock with the original spacer and nut.

- Place the bell/shaft assembly on the support to

check the crankshaft alignment.

- Using a feeler pin gauge and the magnetic base,

measure the bell eccentricity.

- Repeat the measurement at 3 positions (Central,

internal, external).

- In case of anomalies, replace the bell.

Characteristic

clutch bell check: Limit eccentricity.

Admissible limit eccentricity: 0.15 mm

Specific tooling

ATLANTIC 300 i.e. Engine

ENG - 101

Loading...

Loading...