ELECTRICAL SYSTEM UNIT

Name Torque in Nm

Screw fixing voltage regulator to electrical component support-

ing plate

6 ± 20% (4.4 ftlb)

Screw fixing control unit to electrical component supporting

plate

6 ± 20% (4.4 ftlb)

Screw fixing coil to chassis 5 ± 20% (3.7 ftlb)

Starter motor cable fixing nut 5 ± 20% (3.7 ftlb)

Screw fixing electrical component plate to chassis 10 ± 20% (7.4 ftlb)

Nut fixing battery cable harness to relay 4 ± 20% (3 ftlb)

Screw fixing battery red cable to main cable harness cable 10 ± 20% (7.4 ftlb)

INSTRUMENT PANEL UNIT

Name Torque in Nm

Screw fixing instrument panel on panel 1 (0.7 ftlb)

Front and rear panel fixing screw 0.5 (0.4 ftlb)

Screw fixing panel to internal shield 1 ± 20% (0.7 ftlb)

Screw fixing panel to curved support 1 (0.7 ftlb)

TANK UNIT

Name Torque in Nm

Screw fixing fuel tank to chassis 5 ± 20% (3.7 ftlb)

Screw fixing pump support to chassis 10 ± 20% (7.4 ftlb)

Ring nut to tank retainer 20 (14.8 ftlb)

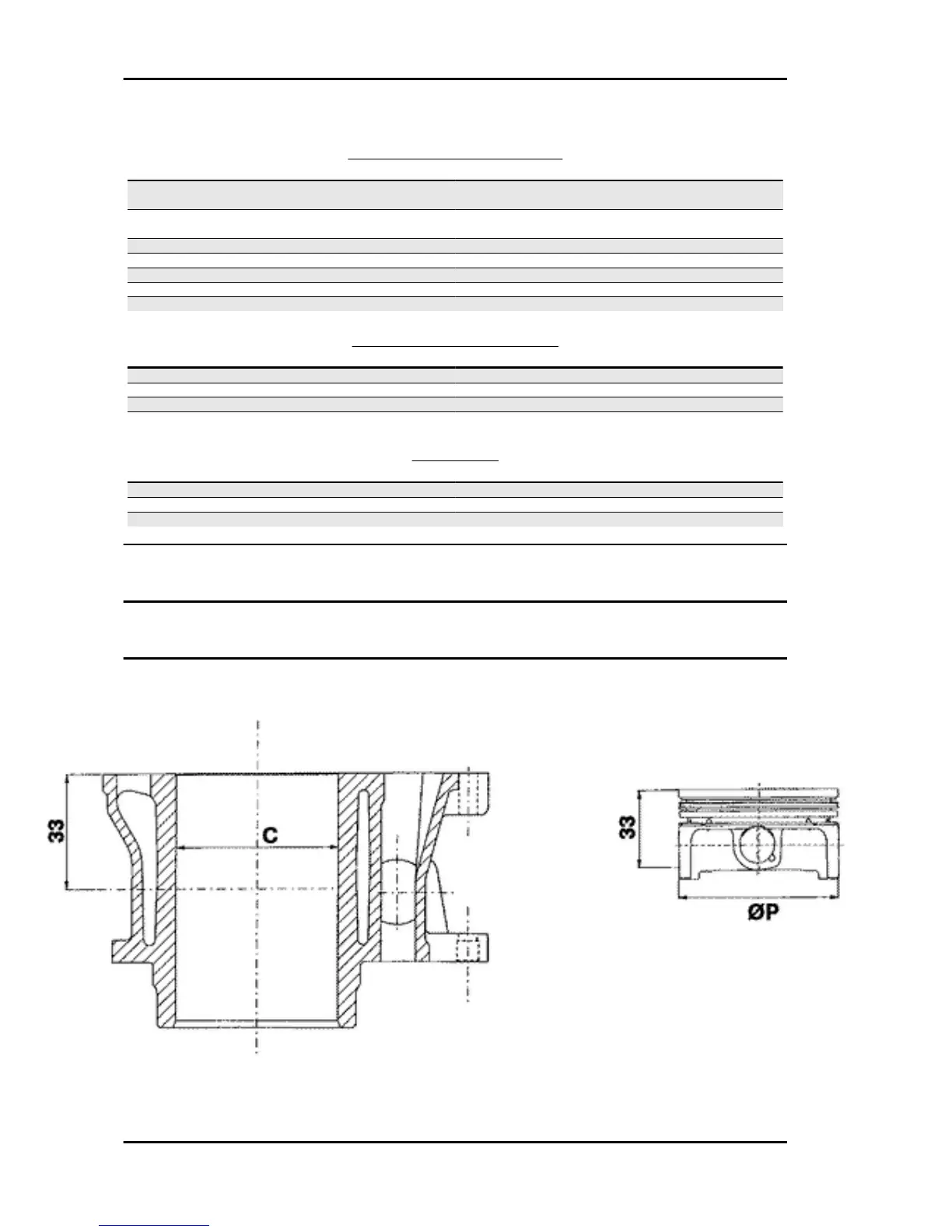

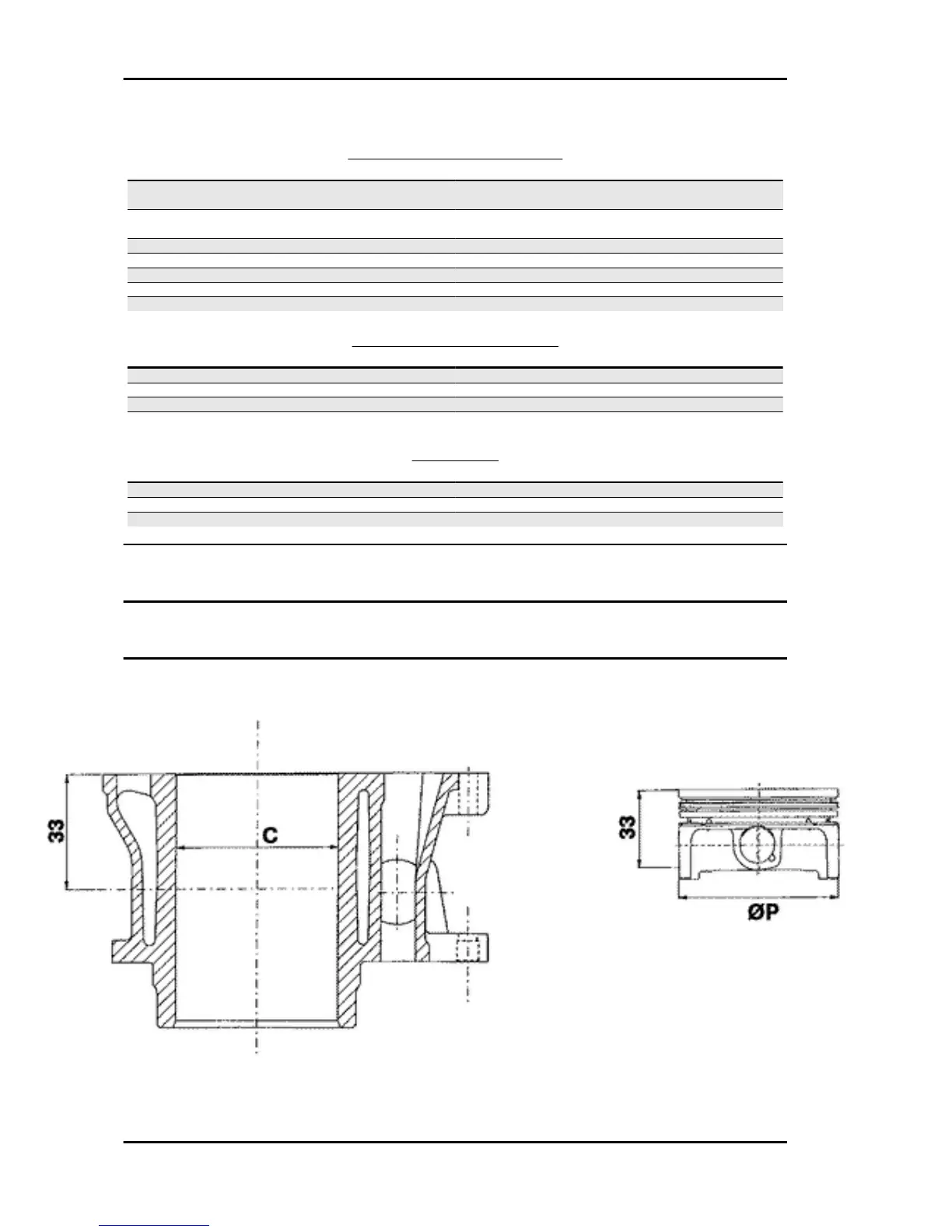

Overhaul data

Assembly clearances

Cylinder - piston assy.

Characteristics ATLANTIC 300 i.e.

CHAR - 18

Loading...

Loading...