23.36

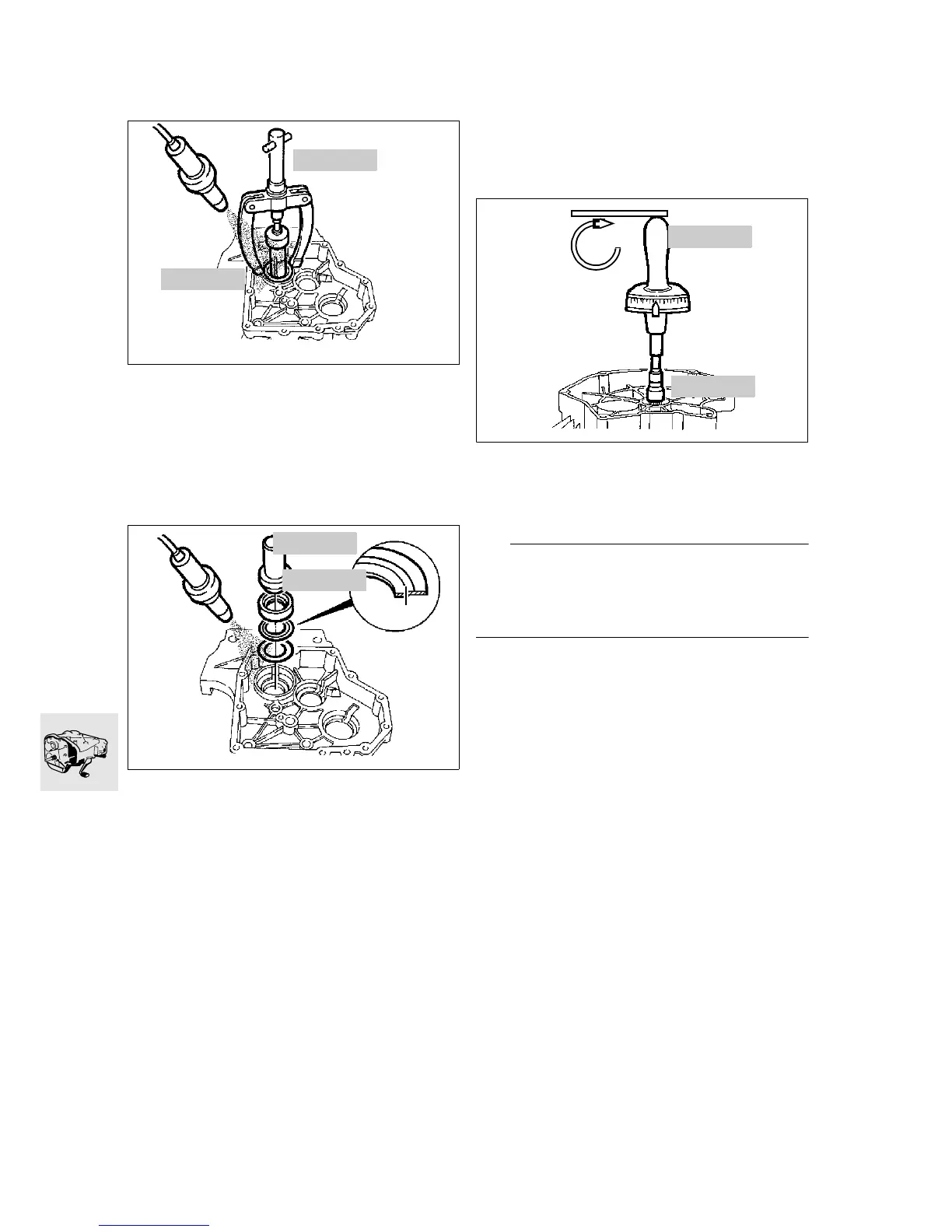

Removing and installing taper roller

bearing race

•

Gearbox cover temperature at bearing seat

100 °C.

•

Depending on tolerance, the bearing shell may

already slide out of its seat when the housing is

heated. If necessary, pull bearing race out with

Kukko counter-support, BMW No. 00 8 562, and

internal puller, BMW No. 00 8 561.

•

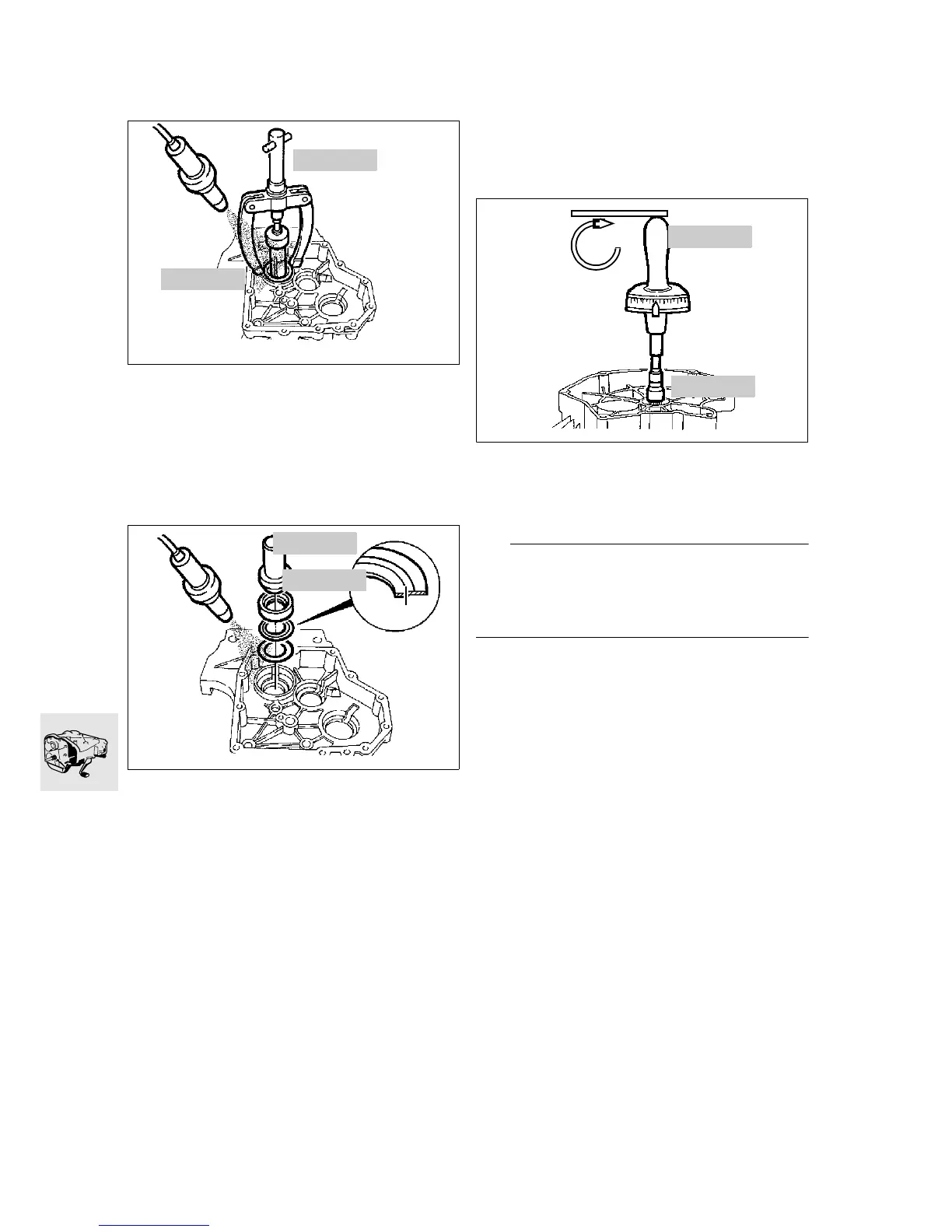

Remove spacing washers/oil baffle plate.

•

Gearbox cover temperature at bearing seat

100 °C.

•

Place shims of the calculated thickness in the

gearbox cover/include the oil retaining plate (1).

•

Using drift, BMW No. 23 4 670, and handle,

BMW No. 00 5 500, insert the bearing race in the

gearbox cover while it is still hot.

Checking friction coefficient of input

shaft taper roller bearing

•

Install gearbox cover

X Tightening torque:

Retaining screws.......................................... 10 Nm

•

Using adapter, BMW No. 23 3 670, and friction

meter, BMW No. 00 2 570, check friction in the

input shaft taper roller bearing by turning at

app. 1 revolution per second.

e Caution:

To check friction coefficient of taper roller bearing

on input shaft, only install the input shaft in the gear-

box.

Bearings must be oiled.

Friction value:

Preload 0.2 mm (0.00787 in) =

friction value 0.5 – 1.0 Nm

00 8 562

00 8 561

j

100

RS230030

00 5 500

23 4 670

1

j

100

RS230032

00 2 570

23 3 670

RS230291

Loading...

Loading...