6 Section 1: Diagnostic Introduction

IMPORTANT:

• Use care to avoid deforming connector

terminals, either by forcing the probe too far

into the cavity or by using a probe that is too

large. If terminal damage is suspected, test

for proper terminal contact.

• A deformed terminal can cause a poor

connection resulting in intermittent problems

or even complete component failure. Do not

use paper clips or other substitute devices

as they also can damage terminals.

• Do not probe through connector seals, wire

insulation, secondary ignition wires, boots,

etc. Damage can occur that is not readily

apparent and tiny holes can result in water

intrusion, which leads to corrosion and

eventual component failure.

Avoiding ECM Damage

CAUTION: A surge in voltage, current

or both, is called a voltage spike. Voltage

spikes can cause major damage to the ECM.

1. To avoid ECM failure due to accidentally

induced voltage spikes, always observe the

following precautions:

• Do not start engine if battery cable

connections are loose.

• Do not use a battery charger to start engine.

• Turn Ignition OFF before disconnecting and/

or connecting battery cables.

• When disconnecting battery, always

disconnect battery negative (-) cable fi rst.

• When connecting battery, always connect

battery positive (+) cable fi rst.

• When charging battery, turn Ignition OFF

and remove battery negative cable (black)

from battery negative (-) terminal.

2. Do not spray water at or around ECM.

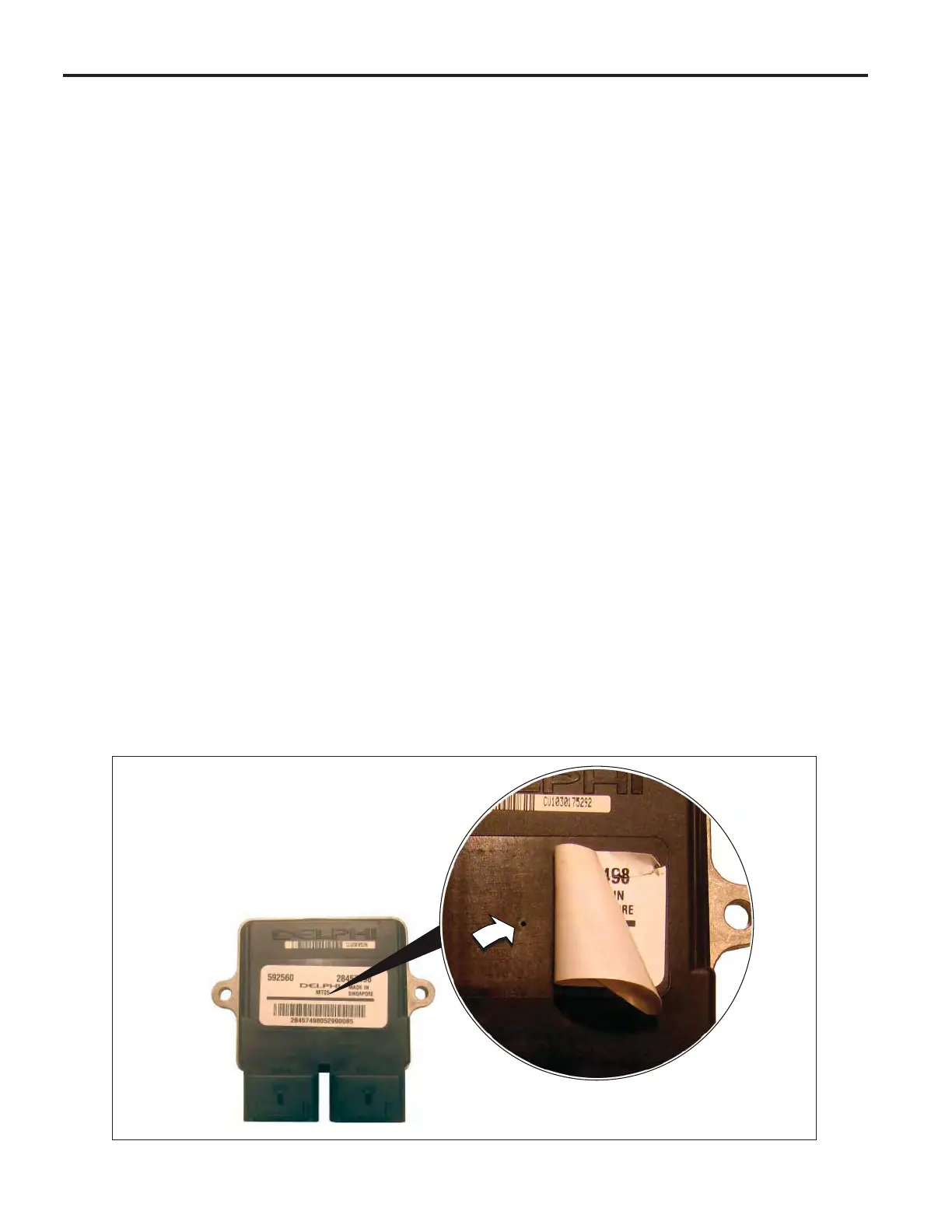

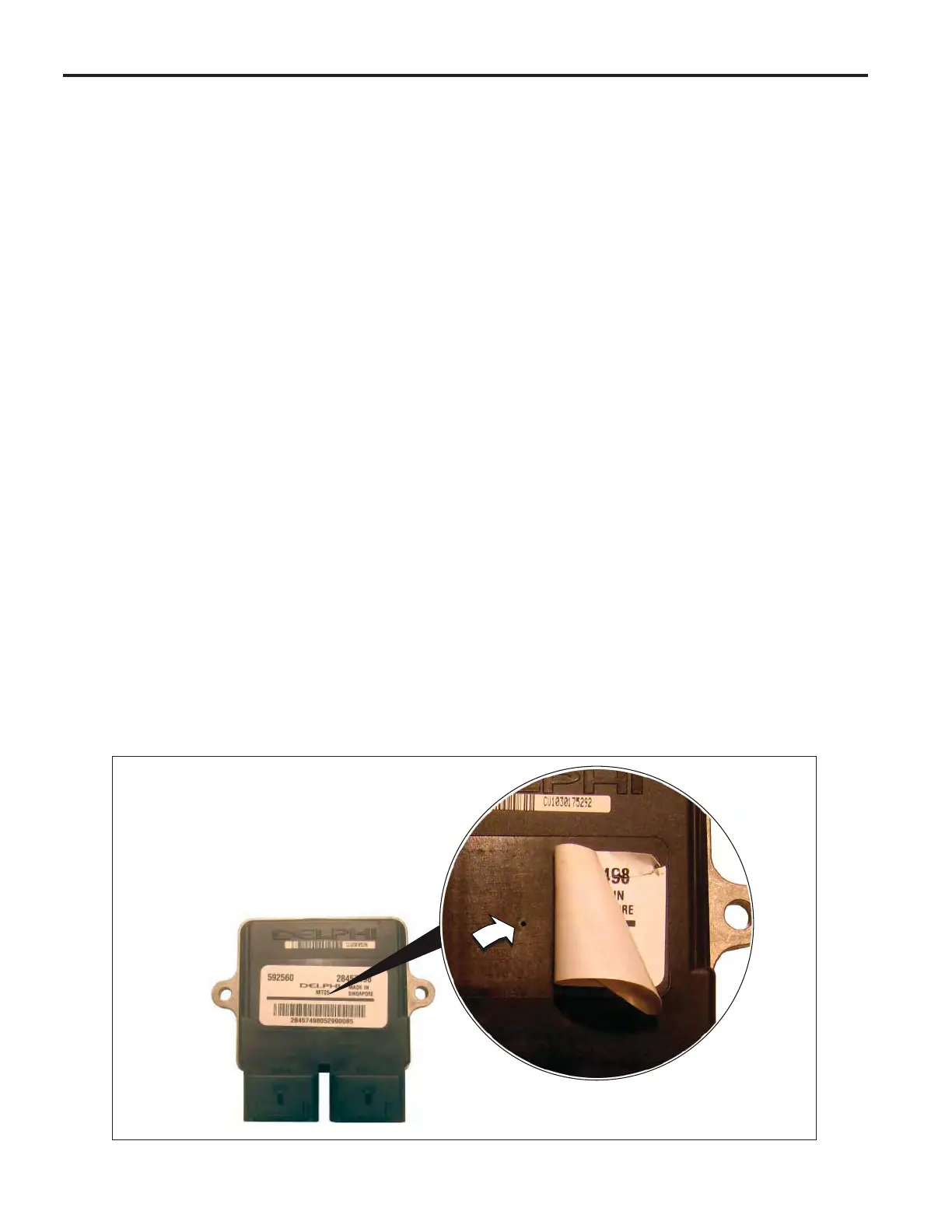

NOTE: See Figure 1-3. A pin hole centered

under the adhesive label is used in manufac-

turing to determine the integrity of the potted

seal. If the label peels or becomes torn, worn

or abraded, exposure of the hole can allow

water or moisture to intrude, leading to corro-

sion and eventual ECM failure.

Figure 1-3 Protect ECM From Water Intrusion.

Loading...

Loading...