Chapter 7 Optional Accessories MS300 (High Speed Model)

7-20

Installation

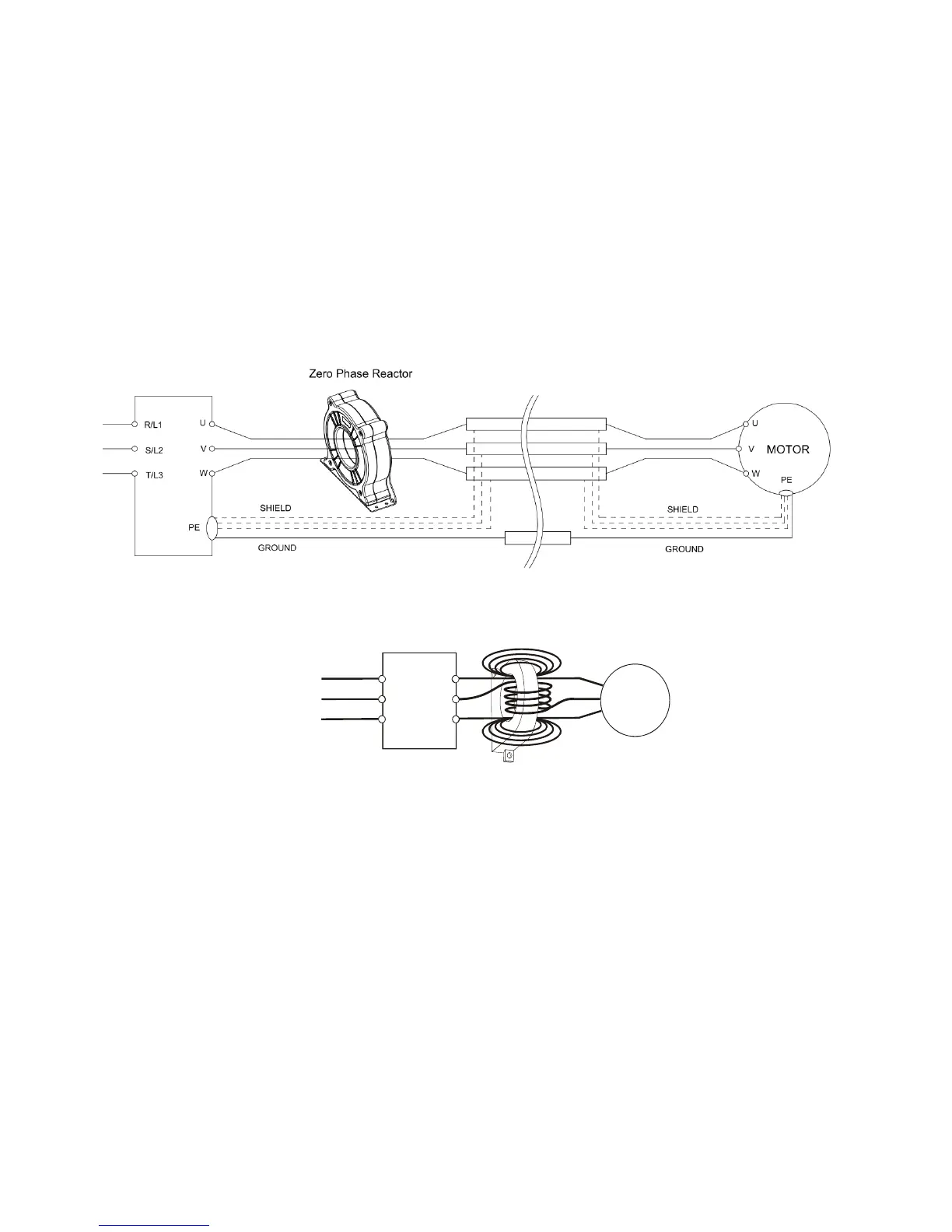

During installation, please pass the cable through at least one zero-phase reactor.

Use a suitable cable type (insulation class and wire section) so that the cable passes easily through the

zero-phase reactor. Do not pass the grounding cable through zero-phase reactor; only pass the motor

wire through.

With longer motor cables the zero-phase reactor can effectively reduce interference at the motor

output. Install the zero-phase reactor as close to the output of the drive as possible. Figure A is the

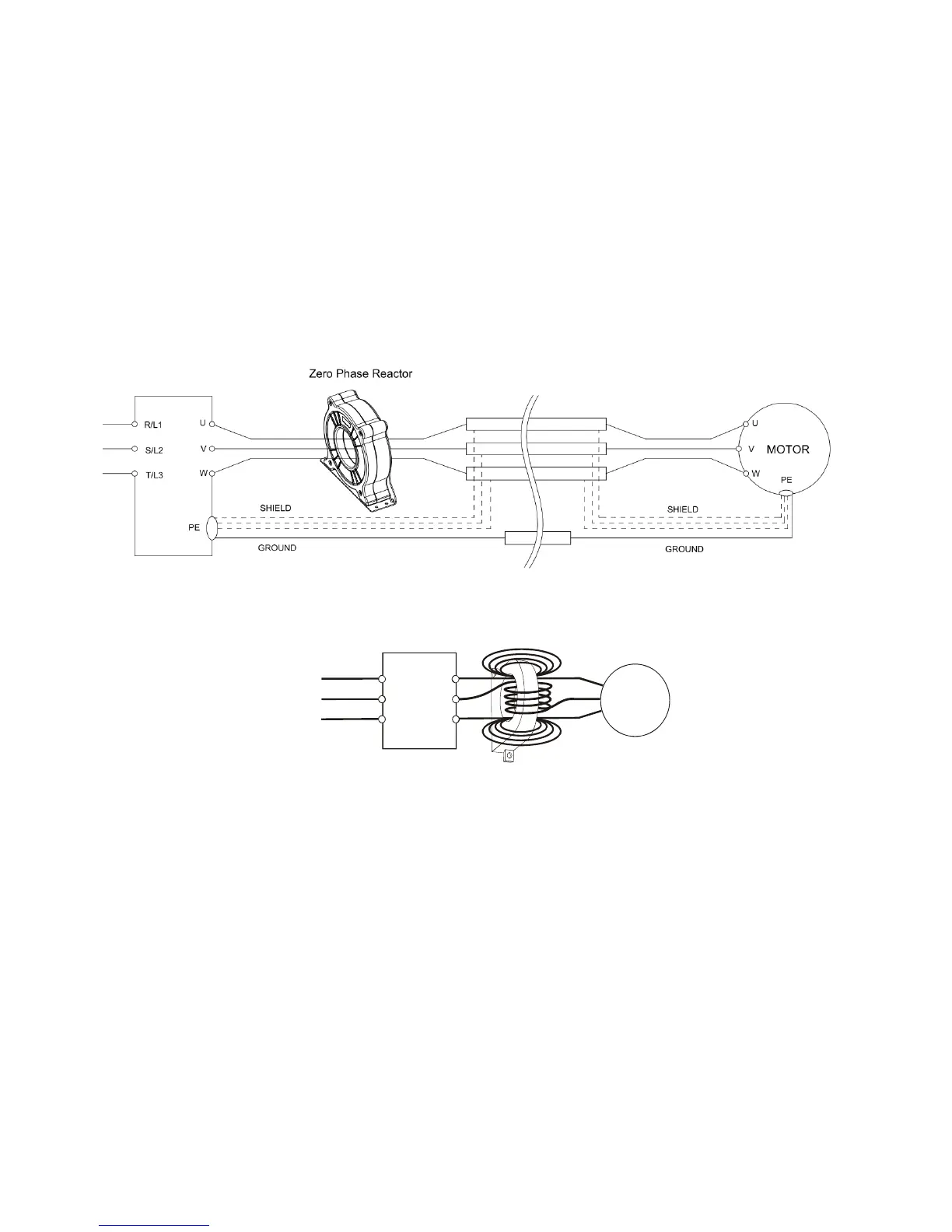

installation diagram of a single turn zero-phase reactor. If the diameter allows several turns, the

installation of a multi-turn zero-phase reactor is as shown in Figure B. The more turns, the better the noise

suppression effect.

Figure A: Single turn wiring diagram of a shieling wire with a zero-phase reactor

Power

Supply

Zero Phase Reactor

MOTOR

U/T1

V/T2

W/T3

R/L1

S/L2

T/L3

Figure B: Multi-Turn Zero Phase Reactor

Installation notices

Install the zero-phase reactor at the output terminal of the frequency converter (U.V.W.).

After the zero-phase reactor is installed, the electromagnetic radiation and load stress emitted by the

wiring of the frequency converter is reduced. The number of zero-phase reactor required for the drive

depends on the length of wiring and the voltage of the drive.

The normal operating temperature of the zero-phase reactor should be lower than 85 °C (176 °F).

However, when the zero-phase reactor is saturated, its temperature may exceed 85°C (176 °F). Please

increase the number of zero-phase reactors to avoid saturation. The following are reasons that might

cause saturation of the zero-phase reactors. For example: The wiring of the drive is too long; the drive

has several sets of load; the wiring is in parallel; the drive uses high capacitance wiring. If the

temperature of the zero-phase reactor exceeds 85 °C (176 °F) during the operation of the drive, the

number of the zero-phase reactor should be increased.

Loading...

Loading...