Emerson Process Management GmbH & Co. OHG 2-9

X-STREAM Non-Incendive

Instruction Manual

HASXENE-IM-EX

12/2014

2

Installation

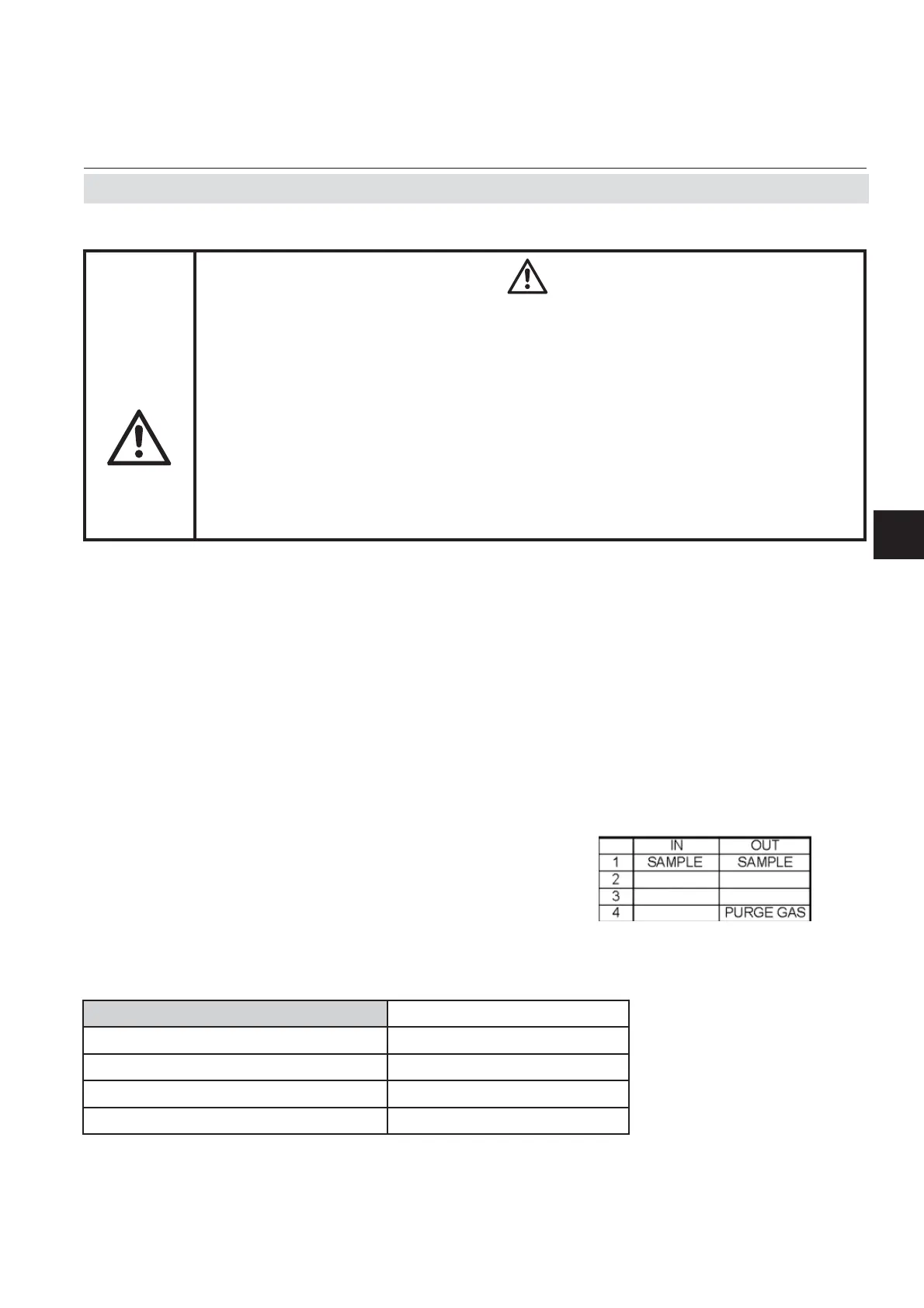

Gas connectors are accessible from the out-

side, on the underside of the instrument.

The number and confi guration of the gas in-

lets and outlets depends on the use, the unit

is to be put to, and is noted on a sticker on

the underside of the instrument next to the

connectors.

To simplify installation, we recommend label-

ling the gas lines in accordance with these

markings. This avoids confusion, should

the analyzer need to be disconnected for

maintenance.

Should it be necessary to open

the gas lines, the gas connectors should be

sealed with PVC caps, to prevent pollution by

moisture, dust, etc.

See fi gures 2-2 and 2-3 for an arrangement

of gas in- & outlets.

All connections are labeled (as shown in the

fi gure below):

Fig. 2-4: Labelling of Gas Connectors (example)

Gas connections

Gas connections

max number 8

max for purging (incl. / separate) 2 incl.

material Stainless steel

sizes 6/4 mm;

1

⁄4"

2.6 Installation - Gas Connections

TRACE OXYGEN MEASUREMENTS

The sensor for trace oxygen measurements is a consumable.

Remaining lifetime counts down when the sensor is in contact with oxygen.

For above reasons, the analyzer is shipped with the sensor as extra item in a

sealed bag! The sensor must be installed before analyzer startup, according

the instructions shipped with the sensor!

Do not use plastic tubing for trace oxygen measurements as it can permeate

oxygen from the ambient air and cause higher than expected oxygen

readings.

Note!

X-STREAM gas analyzers feature at maxi-

mum eight gas connectors. So, parallel tubing

is not possible for fi ve channel confi gurations

(at least two out of fi ve channels need to be

serial tubed)!

Loading...

Loading...