Maintenance 7. Joint #3

LS20-B Rev.4 119

Joint #3 brake

Removal

Push down the shaft to its lower limit while pres

sing the brake release switch.

Be sure to keep enough space and prevent

the end effector hitting any

The brake release switch is applied to both Joints #3 and Joint #4.

When the brake release switch is pressed, the respective brakes of the Joint #3 and Joint

#4 are

released simultaneously.

shaft falling and rotating while the brake release switch is

because the shaft may be lowered by the weight of an end effector.

Arm Top Cover.

For details, refer to Maintenance: 3.1 Arm Top Cover.

sheet bundling the motor cables.

Cut off the wire tie fixing the cable

s to the belt tensioner.

o not cut the wire tie (in the duct fittings outlet) that binds the cables to the duct

will be used again. Be careful not to lose them.

Clip Band

Wire Tie

Duct Plate

Silicon Sheet

Clip Band

Duct Plate

User Plate

Belt Tensioner

Disconnect the following connectors.

Connectors: X231, X43, BR3

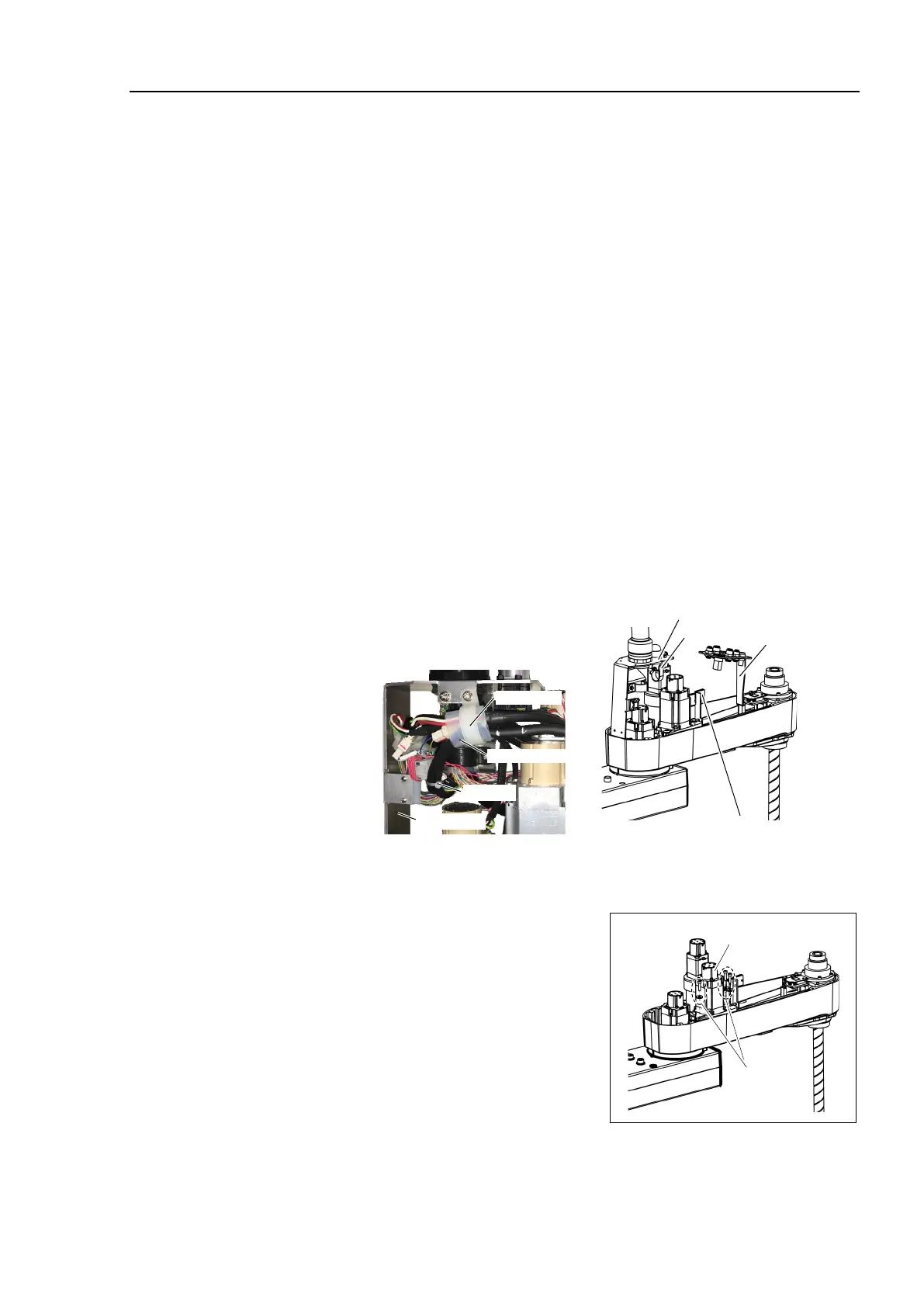

fixing the Joint #3 motor

The washers for slotted holes will be used

again when installing the Z belt.

Be careful

Joint #3

Motor Unit

3-M5×20

+ washer for

slotted hole

Loading...

Loading...