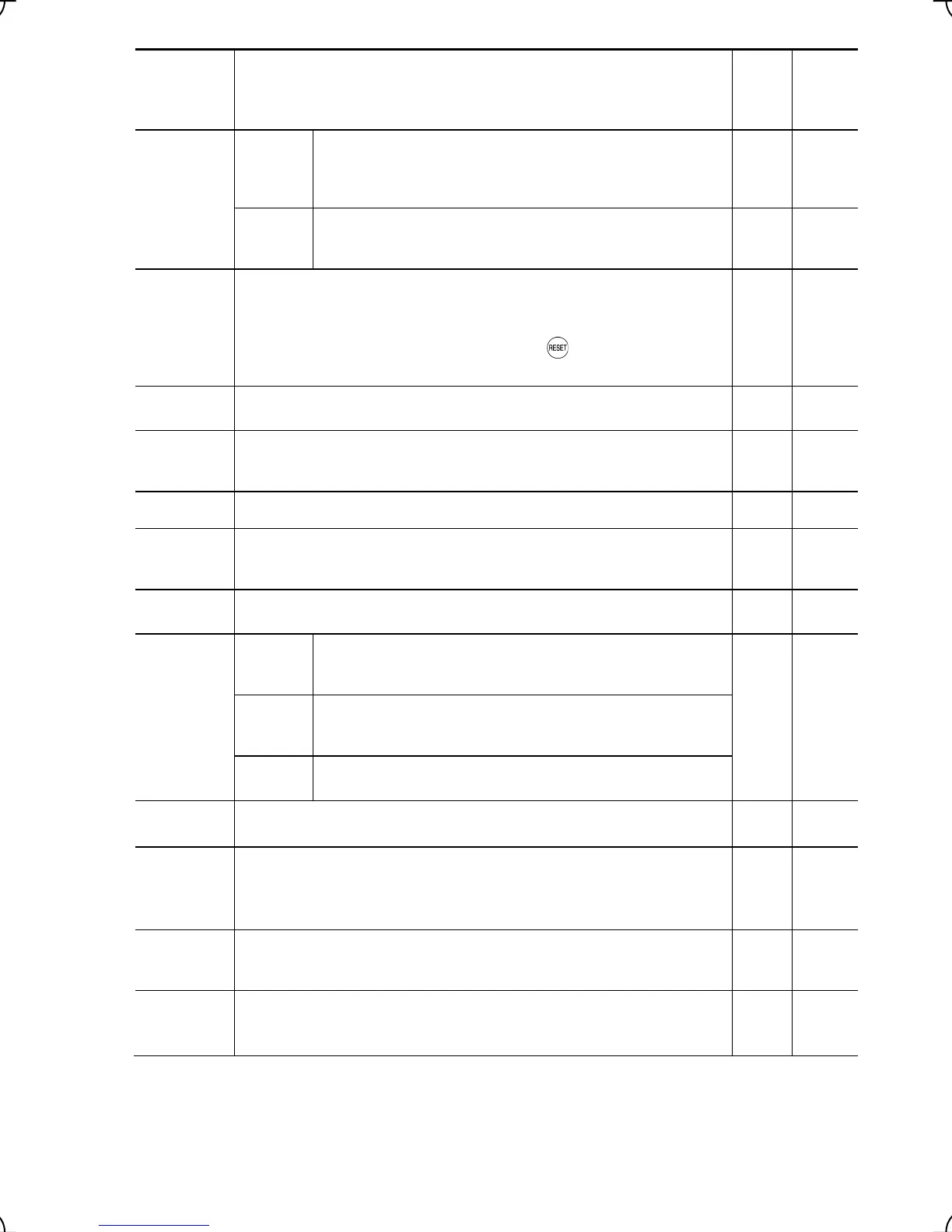

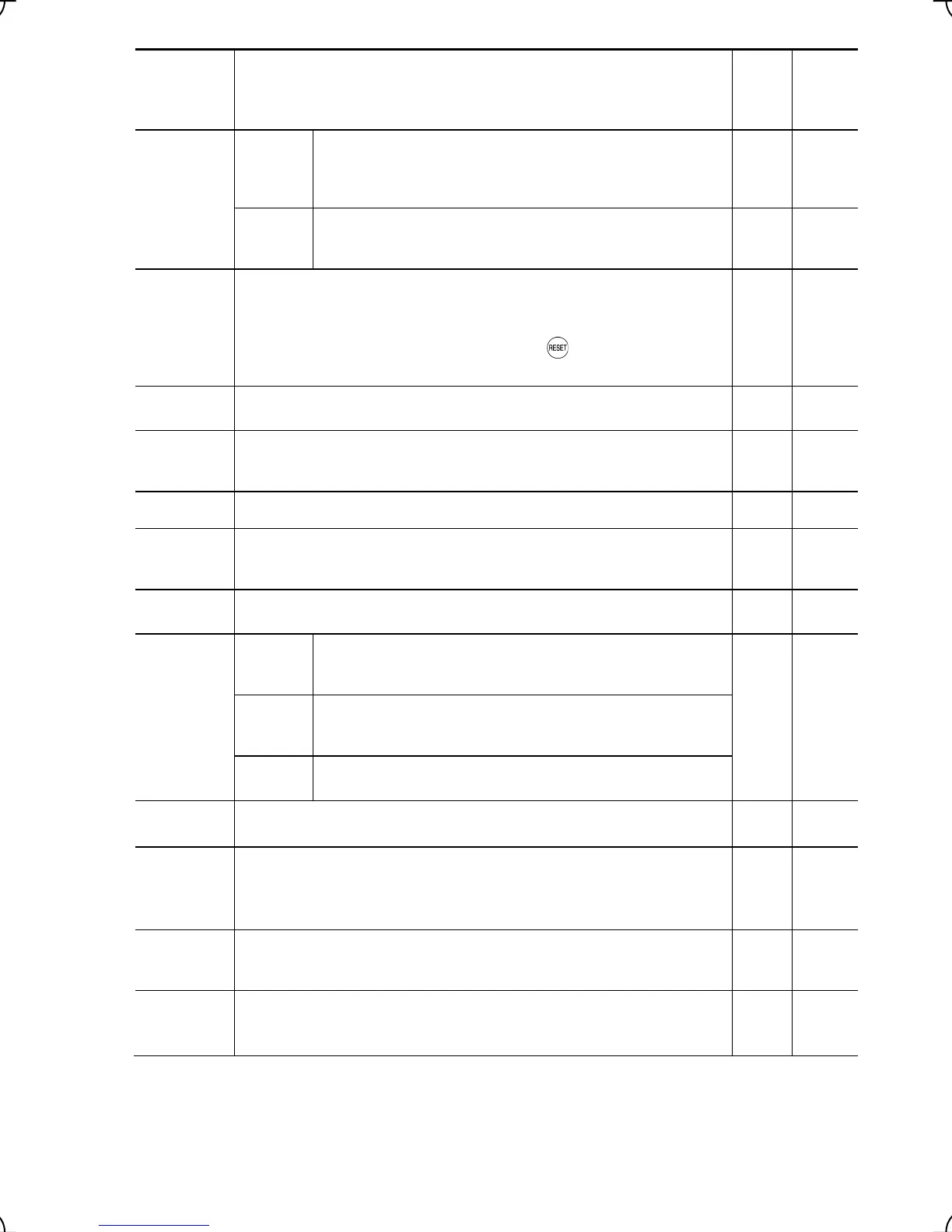

8-11

Name Description

LED

monitor

displays

*1

Alarm

output

[30A/B/C]

Motor

protection

Electronic

thermal

The inverter is stopped upon an electronic thermal function setting

to protect the motor. The standard motor and the inverter motor are

protected in the range of all the frequencies. The operation level

and thermal time constant can be set.

0l1

Yes

PTC

thermistor

A PTC thermistor input stops the inverter to protect the motor. The

PTC thermistor is connected between terminals V2 and 11 to set

switch on the control PC board and function codes.

0h4

Yes

Alarm relay

output

(for any alarm)

- The inverter outputs a relay contact signal when the inverter issues an alarm

and stops the inverter output.

< Alarm Reset >

The alarm stop state is reset by pressing the

key on the multi-function

keypad (option) or by the digital input signal RST.

— Yes

Memory error Data is checked upon power-on and writing to detect any fault in the memory and

to stop the inverter if any.

er1

Yes

Keypad

communication

error

Multi-function keypad (option) is used to detect a communication fault between

the keypad and inverter main body during operation and so on and stop the

inverter if any.

er2

Yes

CPU error Detect a CPU error caused by noise and so on and stops the inverter.

er3

Yes

Option

communication

error

When PG option card is used, a fault of communication with the inverter main

body is detected to stop the inverter.

er4

Yes

Option error When each option card is used, the option side detects a fault to stop the

inverter.

er5

Yes

Operation

error

Brake

status

error

If the braked status input BR KE does not follow the brake command

BRKS, the inverter stops.

er6

Yes

Speed

command

error

Attempting to drive the inverter with the same speed data being set

up in any of multistep speed commands (L11 to L18) stops the

inverter.

MC status

error

If the MC status input CS-MC does not follow the MC command

SW52-2, the inverter stops.

Tuning error When tuning failure, interruption, or any fault as a result of tuning is detected

while tuning the motor constant, the inverter is stopped.

er7

Yes

RS485

communication

error

When the connection port of the keypad is connected via RS485 communication

to the network to detect a communication error, the inverter is stopped to display

the error.

er8

Yes

Hardware error

(option

detection)

When using the option card upon an error in the option or due to a loose

mounting of the card being detected the inverter stops itself.

erh

Yes

EN terminal

circuit error

The inverter detects an error on the EN terminal circuit, and stops itself.

Note that due to the internal circuit error, the reset feature of inverter itself cannot

clear the alarm

ecf

Yes

"—": Not applicable.

*1 When the inverter is equipped with the multi-function keypad, it displays the alarm letters on the LED indicator of the

keypad.

Loading...

Loading...