7-1

Chapter 7 MAINTENANCE AND INSPECTION

Perform daily and periodic inspection to avoid trouble and keep reliable operation for a long time. Take care of the

following items during work.

• Before starting inspection, turn the power OFF. For the inverters with a capacity of 22 kW or below, wait at

least 5 minutes; for those with a capacity of 30 kW or above, wait at least 10 minutes. Further, check that the

charge lamp is unlit and make sure that the DC link bus voltage between the terminals P (+) and N (-) has

dropped below the safe voltage level (25 VDC) using a multimeter or a similar instrument.

Electric shock may occur.

• Maintenance, inspection, and parts-replacement should be made only by authorized persons.

• Take off the wristwatch, rings and other metallic matter before starting work.

• Use insulated tools.

• Never modify the inverter.

Electric shock or injuries could occur.

7.1 Daily Inspection

Visually inspect errors in the state of operation from the outside without removing the covers while the inverter

operates or while it is turned ON.

- Check if the expected performance (satisfying the standard specification) is obtained.

- Check if the surrounding environment satisfies Chapter 2, Section 2.1 "Operating Environment."

- Check for abnormal noise, odor, or excessive vibration.

- Check for traces of overheating, discoloration and other defects.

7.2 Periodic Inspection

Perform periodic inspection by following the items of the list of periodic inspection in Table 7.1. Before performing

periodic inspection, be sure to stop the motor, turn OFF the inverter, and shut down power supply. Then remove

the covers of the control and main circuit terminal blocks.

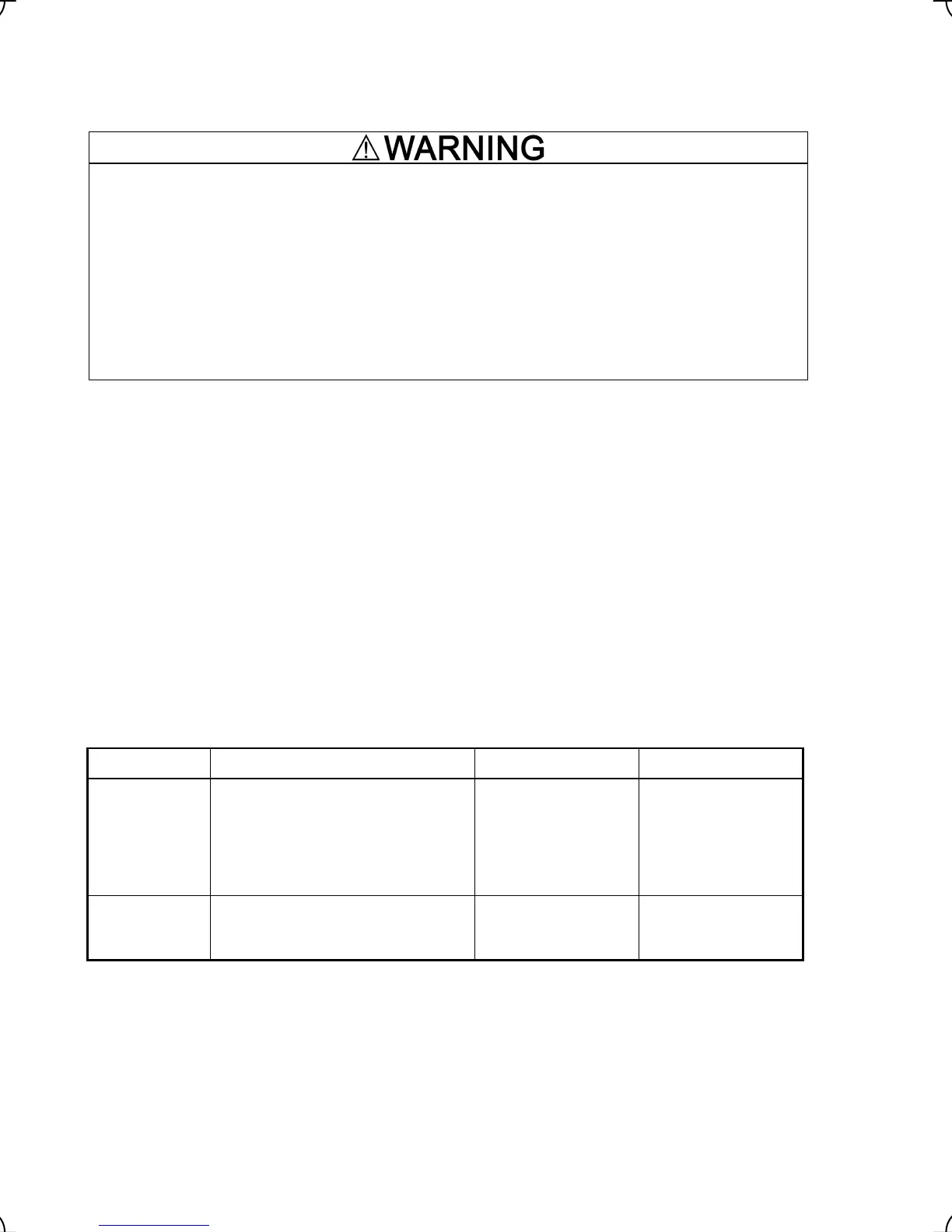

Table 7.1 List of Periodic Inspections

Check part Check item How to inspect Evaluation criteria

Environment

1) Check the ambient temperature,

humidity, vibration and atmosphere

(dust, gas, oil mist, or water drops).

2) Check if tools or other foreign matter

or dangerous objects are left around

the equipment.

1) Check visually or

measure using

apparatus.

2) Visual inspection

1) The standard

specification must be

satisfied.

2) No foreign or

dangerous objects

are left.

Voltage

Check if the voltages of the main and

control circuit are correct.

Measure the voltages

using a multimeter or

the like.

The standard

specification must be

satisfied.

Loading...

Loading...