7-3

7.3 List of Periodical Replacement Parts

Each part of the product has its own service life that will vary according to the environmental and operating

conditions. It is recommended that the following parts be replaced as specified below.

When the replacement is necessary, contact your Fuji Electric representative.

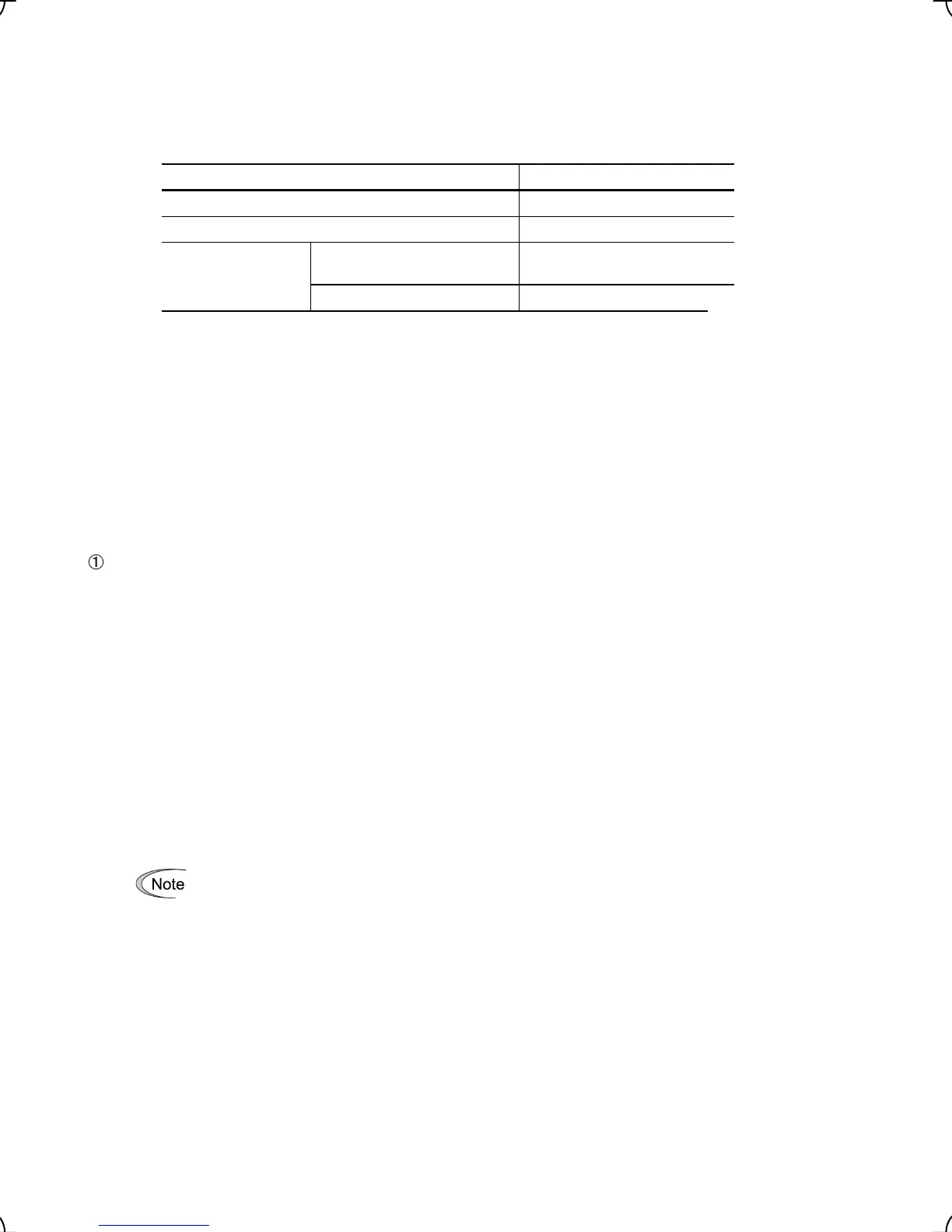

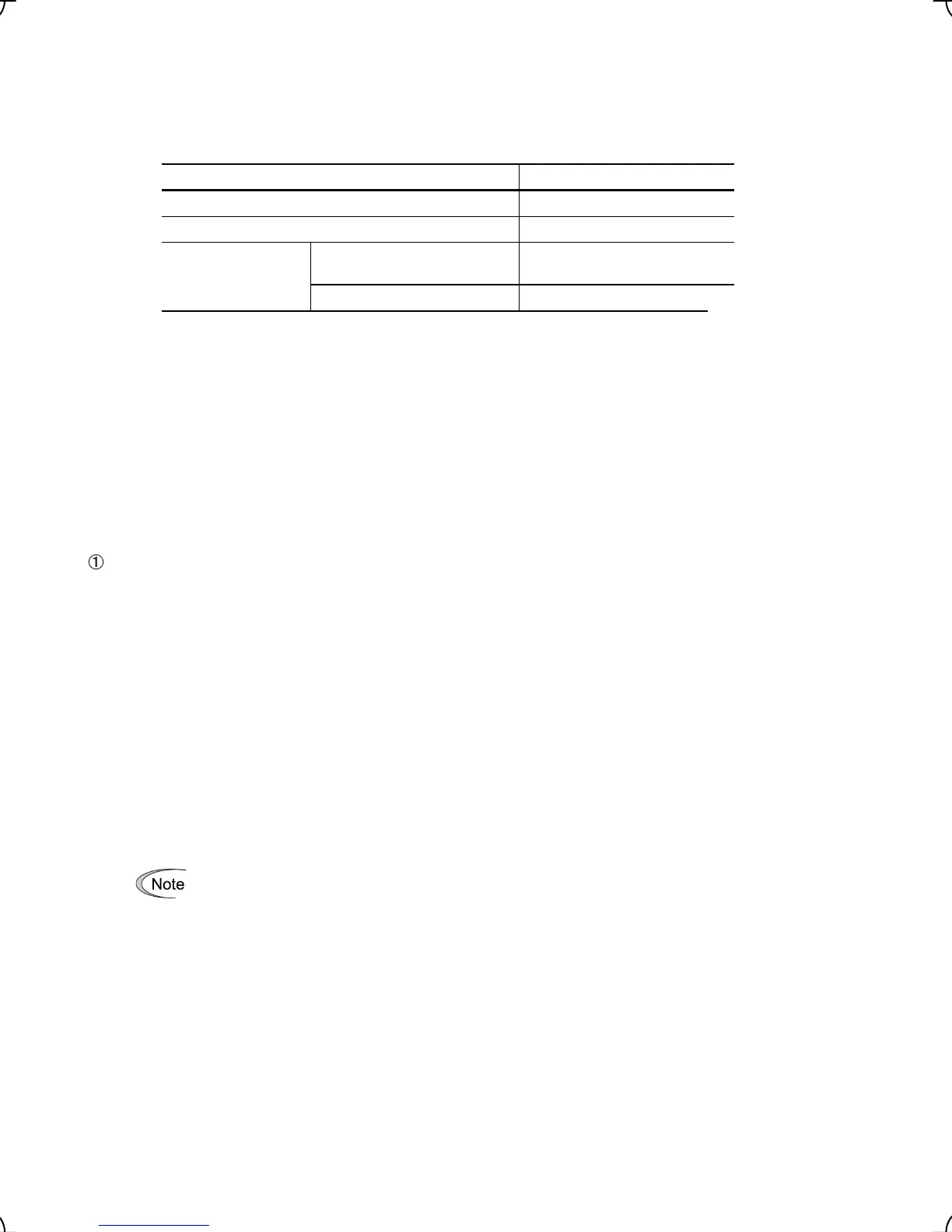

Table 7.2 Replacement Parts

Part name Standard replacement intervals

DC link bus capacitor 7 years

Electrolytic capacitor on the printed circuit board 7 years

Cooling fan

200V series 22kW or below or

400V series 30kW or below

4.5 years

400V series 37kW or above 2.5 years

(Note) These replacement intervals are based on the estimated service life of the inverter at an

ambient temperature of 40℃ in 80% of the rated RMS current. In environments with an

ambient temperature above 40℃ or a large amount of dust or dirt, the replacement intervals

may need to be reduced.

7.3.1 Judgment on service life

(1) Viewing data necessary for judging service life; Measurement procedures

Through Menu 5 "Maintenance Information" in Programming mode, you can view on the optional multi-function

keypad (option) various data (as a guideline) necessary for judging whether key components such as the DC link

bus capacitor, the electrolytic capacitor on the printed circuit board, and the cooling fan are approaching their

service life.

-1 Measuring the capacitance of the DC link bus capacitor (in comparison with that at factory shipment)

Measure the capacitance of the DC link bus capacitor according to the procedure given below. The result will be

displayed on the keypad as a ratio (%) to the initial capacitance at the time of factory shipment.

----------------------------------------------- Procedure for measuring capacitance -----------------------------------------------

1) To ensure validity in the comparative measurement, configure the condition of the inverter as follows.

• Remove the option card (if already in use) from the inverter.

• In case another inverter is connected via the DC link bus to the P(+) and N(-) terminals of the main circuit,

disconnect the wires. (You do not need to disconnect a DC reactor (optional), if any.)

• Disconnect power wires for the auxiliary input to the control circuit (R0, T0).

• If the multi-function keypad is mounted, remove it.

• Turn OFF all the digital input signals fed to terminals [FWD], [REV], [EN], and [X1] through [X8] of the

control circuit.

• If the encoder is wired at terminals (P0, PA, PB, and PZ (if any)), remove it..

• If an external apparatus is attached to terminal [PLC], disconnect it.

• Ensure that transistor output signals ([Y1] ─ [Y4]) and relay output signals ([Y5A/C] and [30A/B/C]) will not

be turned ON.

If negative logic is specified for the transistor output and relay output signals, they are considered

ON when the inverter is not running. Specify positive logic for them.

• Keep the ambient temperature within 25 ±10°C.

2) Switch ON the main circuit power.

3) Confirm that the cooling fan is rotating and the inverter is in stopped state.

4) Switch OFF the main circuit power.

5) Mount the multi-function keypad after five minutes having elapsed, switch ON the main circuit power again.

6) Select Menu 5 "Maintenance Information" in Programming mode and note the reading (relative capacitance

(%) of the DC link bus capacitor).

----------------------------------------------------------------------------------------------------------------------------------------------------

Loading...

Loading...