v

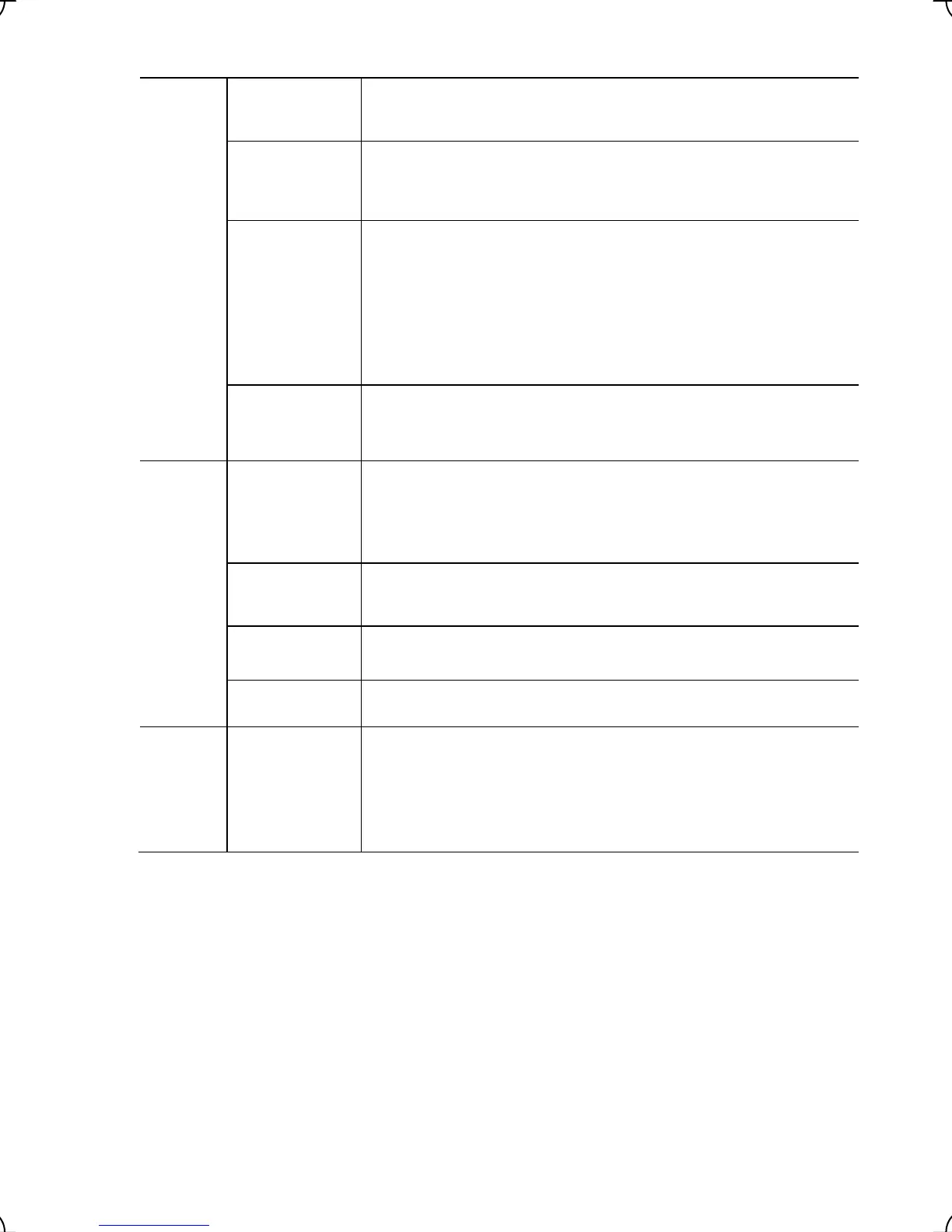

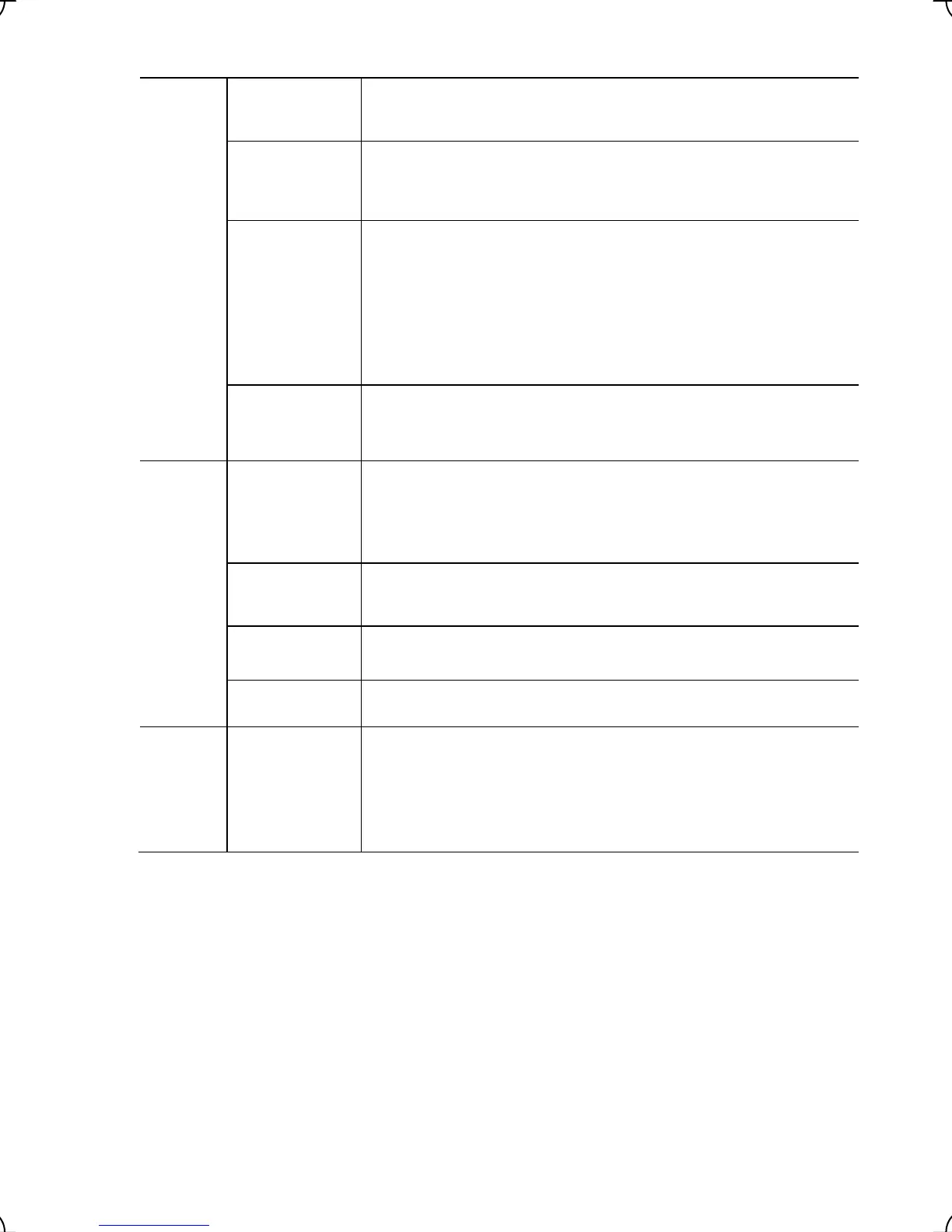

Precautions for use

In running

general-

purpose

motors

Driving a 400V

general-purpose

motor

When driving a 400V general-purpose motor with an inverter using ex-

tremely long wires, damage to the insulation of the motor may occur. Apply

the inverter after consulting the motor maker.

Torque characte-

ristics and tem-

perature rise

When the inverter is used to run a general-purpose motor, the temperature

of the motor becomes higher than when it is operated using a commercial

power supply. In the low-speed range, the cooling effect will be weakened,

so decrease the output torque of the motor.

Vibration

When an inverter-driven motor is mounted to a machine, resonance may

be caused by the natural frequencies of the machine system.

Note that operation of a 2-pole motor at 60 Hz or higher may cause ab-

normal vibration.

* The use of a rubber coupling or vibration dampening rubber is recom-

mended.

* Run your machinery including FRENIC-Lift inverter so as to skip its re-

sonance frequency zone/s.

Noise

When an inverter is used with a general-purpose motor, the motor noise

level is higher than that with a commercial power supply. To reduce noise,

raise carrier frequency of the inverter. Operation at 60 Hz or higher can

also result in higher noise level.

In running

special mo-

tors

Brake motors

For motors equipped with parallel-connected brakes, their braking power

must be supplied from the primary circuit. If the brake power is connected

to the inverter's output circuit by mistake, the brake will not work.

Do not use inverters for driving motors equipped with series-connected

brakes.

Geared motors

If the power transmission mechanism uses an oil-lubricated gearbox or

speed changer/reducer, then continuous motor operation at low speed

may cause poor lubrication. Avoid such operation.

Synchronous mo-

tors

The PG interface card (option) corresponding to the pulse encoder spec-

fication is necessary. Read PG interface card (option) manual.

Single-phase

motors

Single-phase motors are not suitable for inverter-driven variable speed

operation. Use three-phase motors.

Environ-

mental con-

ditions

Installation loca-

tion

Use the inverter within the ambient temperature range from -10 to +45°C.

The heat sink and braking resistor of the inverter may become hot under

certain operating conditions, so install the inverter on nonflammable ma-

terial such as metal.

Ensure that the installation location meets the environmental conditions

specified in Chapter 2, Section 2.1 "Operating Environment."

Loading...

Loading...