•

Torque terminals in accordance with the

information provided in 12 Terminal and

Applicable Wire

•

Follow the motor manufacturer wiring

requirements

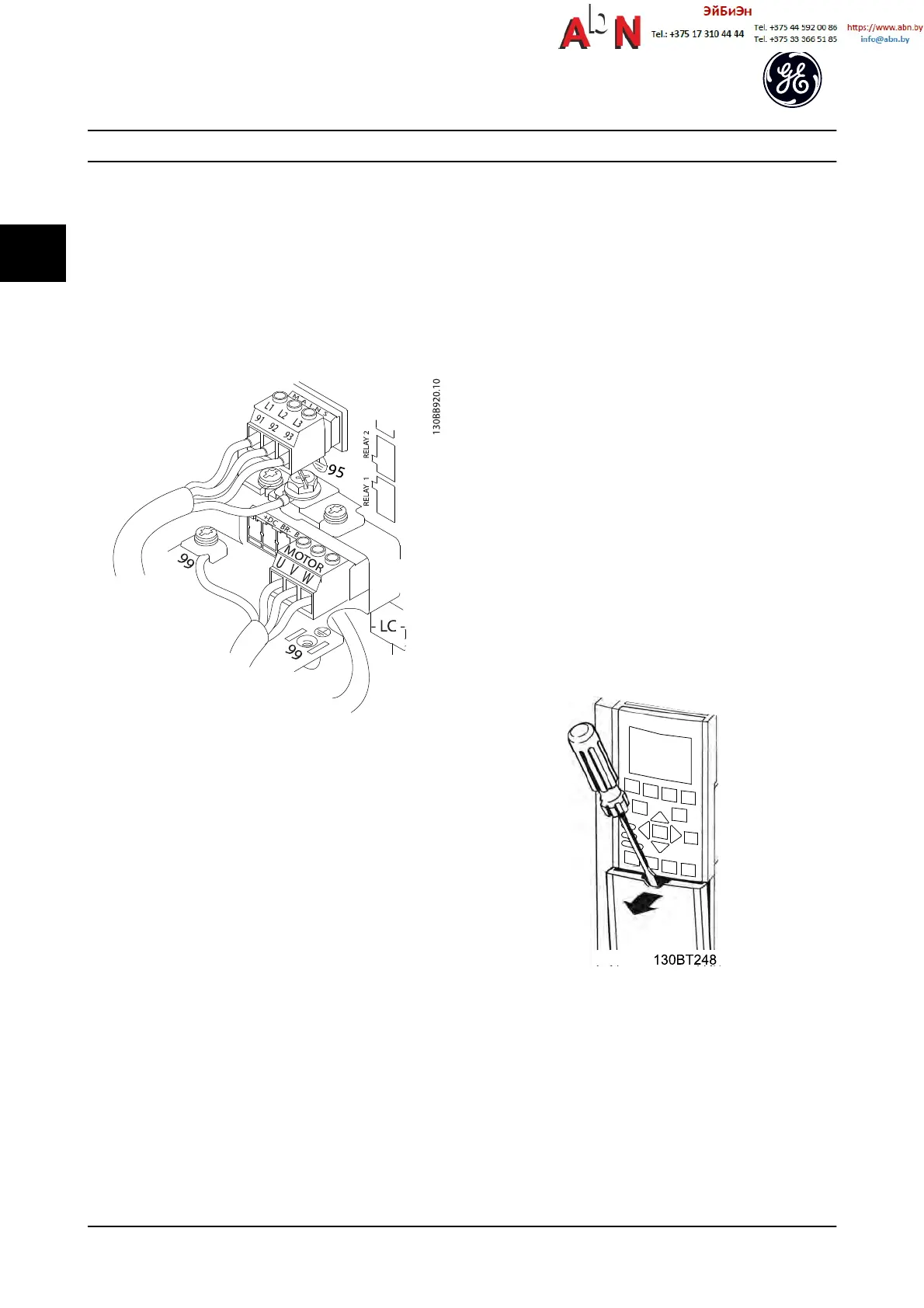

Figure 2.15 represents line power input, motor, and ground

grounding for basic adjustable frequency drives. Actual

configurations vary with unit types and optional

equipment.

Figure 2.15 Example of Motor, Line Power and Ground Wiring

2.5.4 AC Line Power Connection

•

Size wiring based upon the input current of the

adjustable frequency drive. For maximum wire

sizes, see Table 12.1.

•

Comply with local and national electrical codes

for cable sizes.

•

Connect 3-phase AC input power wiring to

terminals L1, L2, and L3 (see Figure 2.15).

•

Depending on the configuration of the

equipment, input power will be connected to the

line power input terminals or the input

disconnect.

•

Ground the cable in accordance with grounding

instructions provided in 2.5.2 Grounding

Requirements

•

All adjustable frequency drives may be used with

an isolated input source as well as with ground

reference power lines. When supplied from an

isolated line power source (IT line power or

floating delta) or TT/TN-S line power with a

grounded leg (grounded delta), set SP-50 RFI Filter

to [0] Off. When off, the internal RFI filter

capacitors between the chassis and the

intermediate circuit are isolated to avoid damage

to the intermediate circuit and to reduce ground

capacity currents in accordance with IEC 61800-3.

2.5.5 Control Wiring

•

Isolate control wiring from high power

components in the adjustable frequency drive.

•

If the adjustable frequency drive is connected to

a thermistor, for PELV isolation, optional

thermistor control wiring must be reinforced/

double insulated. A 24 V DC supply voltage is

recommended.

2.5.5.1 Access

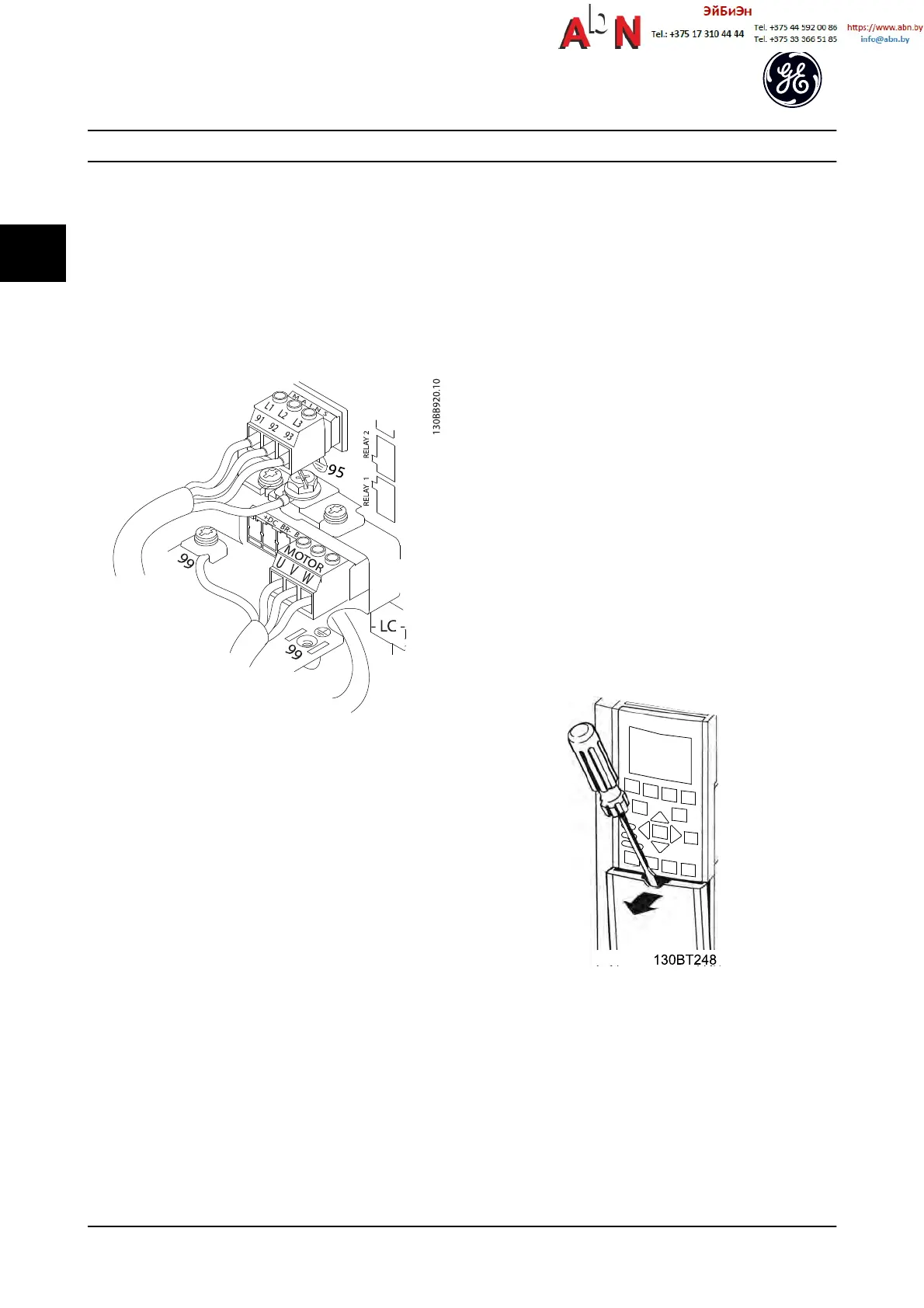

•

Remove access cover plate with a screw driver.

See Figure 2.16.

•

Or remove front cover by loosening attaching

screws. See Figure 2.17.

Tightening torque for front cover is 2.0 Nm for

unit size 15 and 2.2 Nm for unit sizes 2X and 3X.

Figure 2.16 Control Wiring Access for IP20/Open chassis

enclosures

Installation

AF-650 GP

TM

Design and Installation Guide

2-10 DET-767A

2

Loading...

Loading...