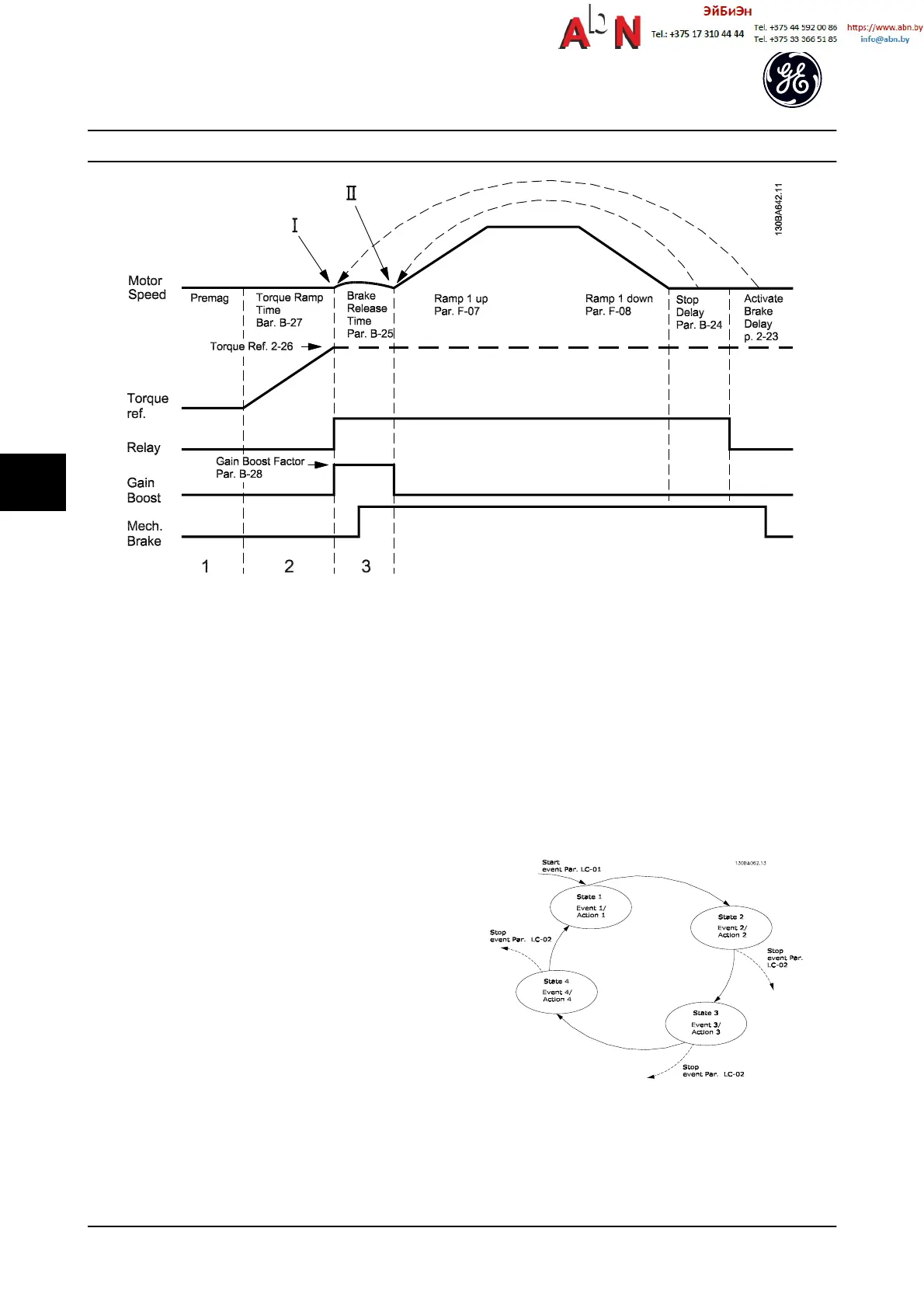

Figure 6.24 Brake release sequence for hoist mechanical brake control

I) Activate brake delay: The adjustable frequency drive starts again from the mechanical brake engaged position.

II) Stop delay: When the time between successive starts is shorter than the setting in B-24 Stop Delay, the adjustable frequency drive starts

without applying the mechanical brake (e.g. reversing).

NOTE!

For an example of advanced mechanical brake control for

hoisting applications, see section Application Examples

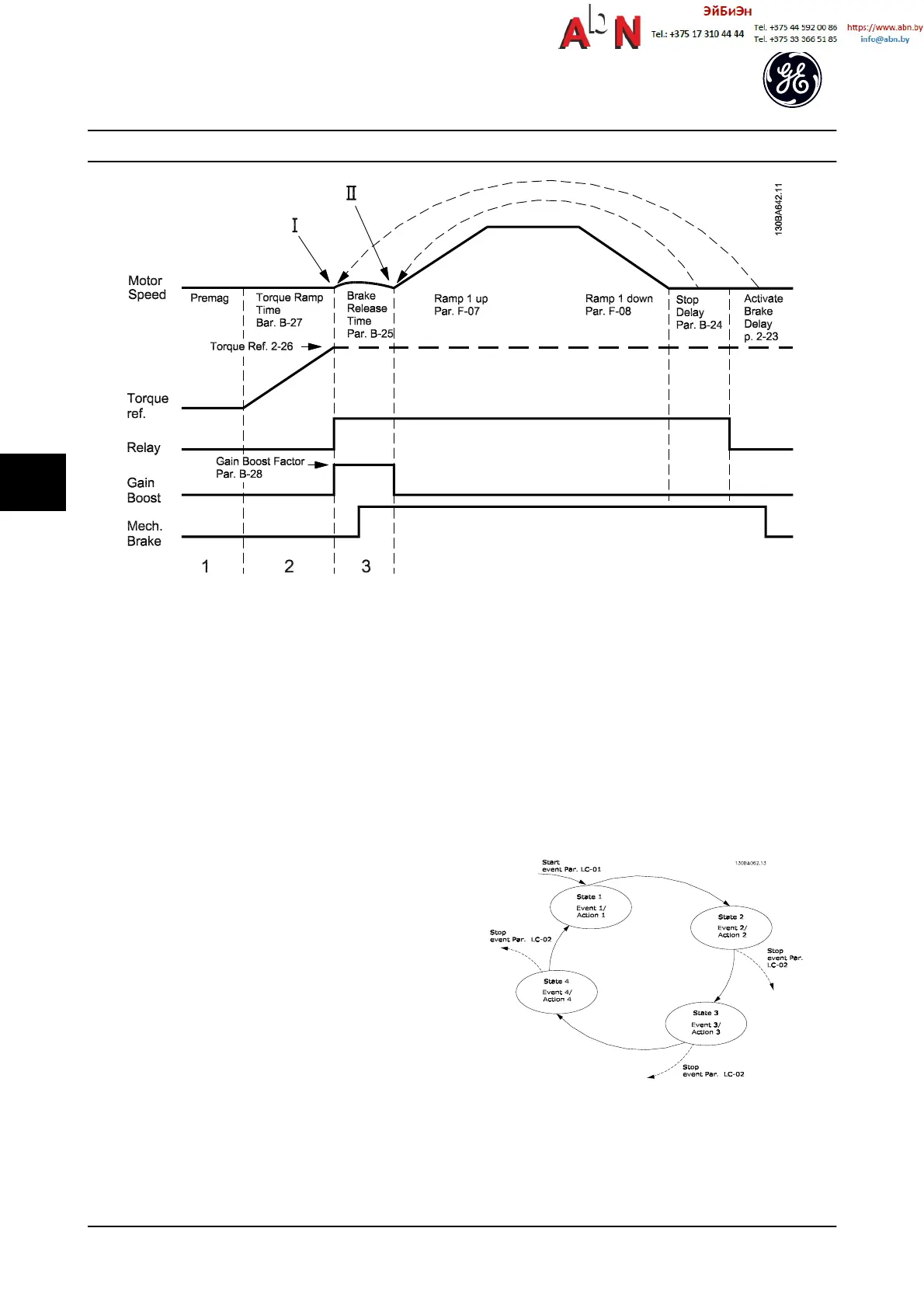

6.7 Logic Controller

Logic Controller (LC) is essentially a sequence of user-

defined actions (see LC-52 Logic Controller Action [x])

executed by the LC when the associated user-defined

event (see LC-51 Logic Controller Event [x]) is evaluated as

TRUE by the LC.

The condition for an event can be a particular status or

that the output from a logic rule or a comparator operand

becomes TRUE. That will lead to an associated action as

illustrated.

Events and actions are each numbered and linked together

in pairs (states). This means that when event [0] is fulfilled

(attains the value TRUE), action [0] is executed. After this,

the conditions of event [1] will be evaluated and if

evaluated TRUE, action [1] will be executed and so on.

Only one event will be evaluated at any time. If an event is

evaluated as FALSE, nothing happens (in the LC) during

the current scan interval and no other events will be

evaluated. This means that when the LC starts, it evaluates

event [0] (and only event [0]) each scan interval. Only when

event [0] is evaluated TRUE, will the LC execute action [0]

and start evaluating event [1]. It is possible to program

from 1 to 20 events and actions.

When the last event/action has been executed, the

sequence starts over again from event [0]/action [0]. The

figure shows an example with three event/actions:

Figure 6.25

Application Setup Examples

AF-650 GP

TM

Design and Installation Guide

6-26 DET-767A

6

Loading...

Loading...