ADL500 • Quick installation guide - Specifications and connection 93

A.4 - Brake monitoring system

A.4.1 Introduction

The brake monitoring function in the ADL500 series of products enables implementation of the automatic brake moni-

toring function as required by EN 81-20:2020 section 5.6.7.3.

Two functional elements are required to implement the brake monitoring function:

1. Management of the Brake fault alarm;

2. Resetting of the Brake fault alarm.

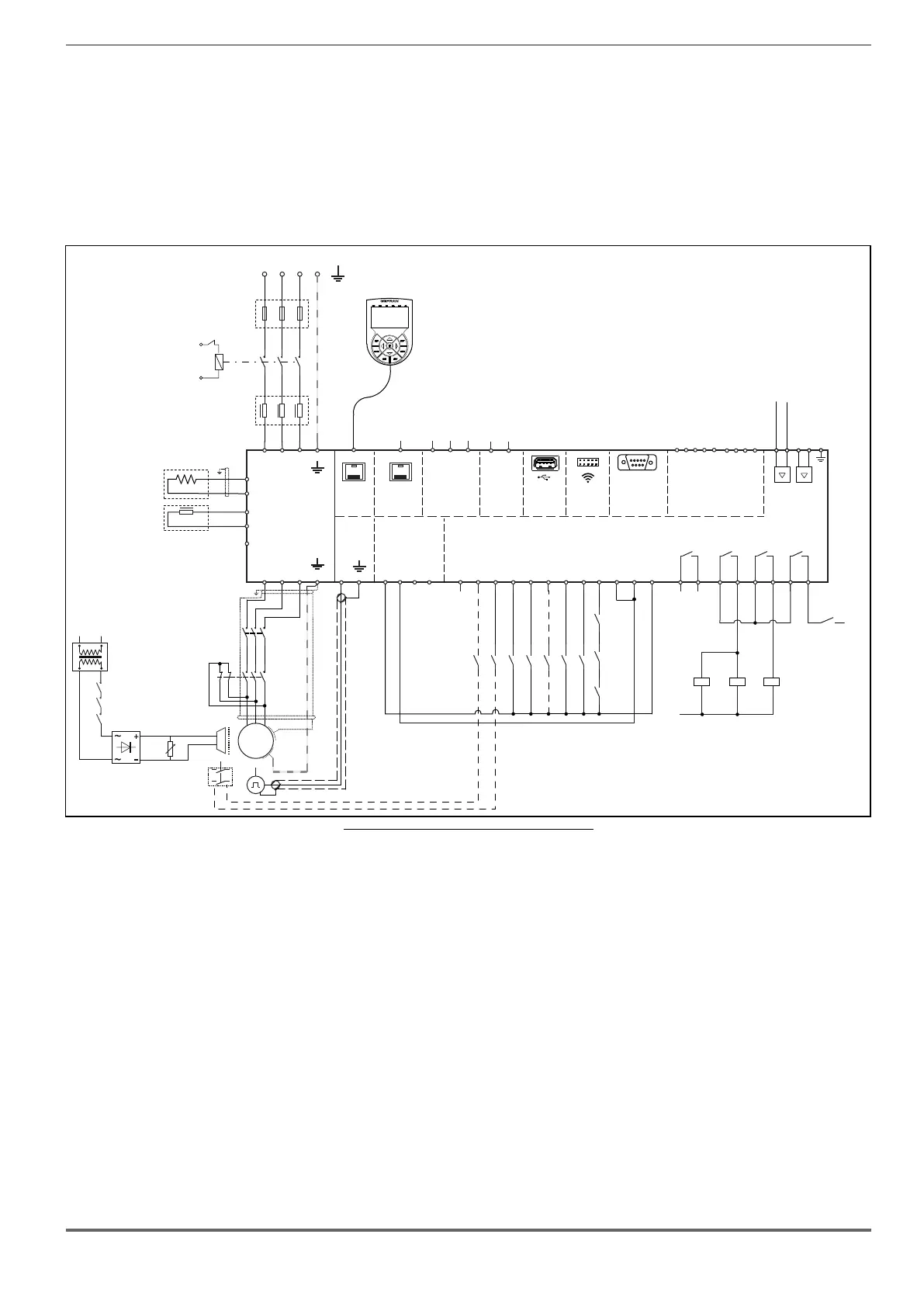

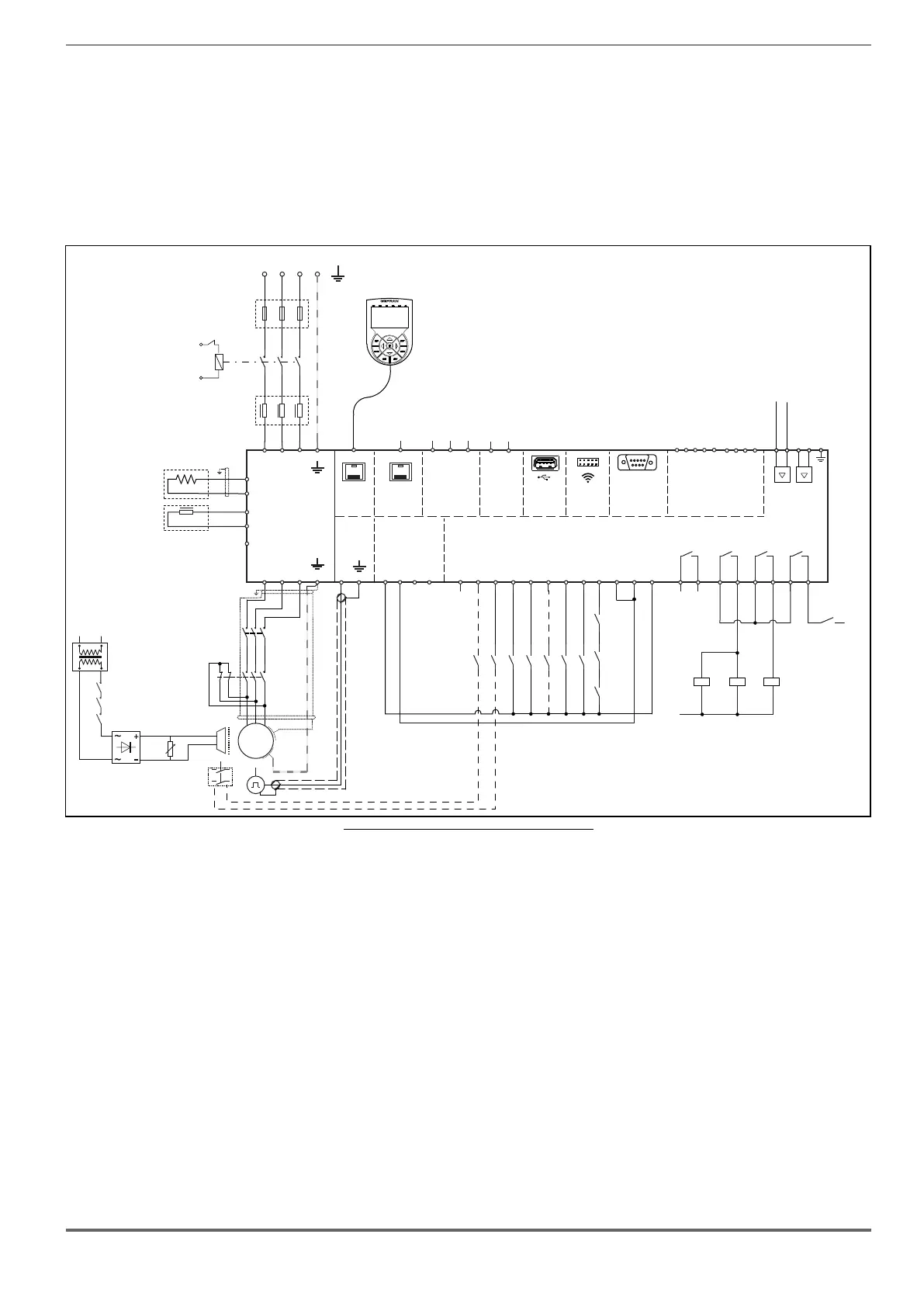

The basic wiring diagram for implementing this function is shown in Figure 5.1.

1

2

3

4

5

6

M

3

~

DC CHOKE

L2

(ADL550: 4 to 22kW)

ADL550

U1

V1 W1

U2

V2

W2

DOOR

CAN

DI8

DI7

DI6

DI5

DI4

DI3

DI2

DI1

ENHW

DICM

0VOUT

24VOUT

L1 L2 L3

KEYPAD

ETH-PC

T1 T2 T3

1 2 3 4 5 6 7 8 9 10 11 12

PE

PE

50

51

SH

H

L

D

C

BR1

BREAKING

RESISTOR

BR2

BRAKE

CONTACTOR

OK

DRIVE

52

53

54

55

CONTACTOR

RUN

56

57

L1

A1

A2

A1

A2

A1

A2

K2M

K3M BR

BRAKE

K2M

K3M

BR

TRAFO

3 Phase Mains

FBR

5

6

3

4

1

2

K2M

5

6

3

4

1

2

K3M

Emergency

Failure

(optional)

EN+

EN-

XE

XER

PE

OK1

OK2

C1

OPTIONAL

AC CHOKE

L1

OPTIONAL

F1

SFTY-STO

+24V (EXT)

+24V

0

EXP-DCP

(optional)

USB 2.0

DI4X

1

DI3X

2

DI2X

3

DI1X

4

DICM

5

EXP-4DI+2RO

(optional)

RO_5O

1

RO_5C

2

RO_6O

3

RO_6C

4

-

-

+

+

1 2 3 4

MOT-

MOT+

AI_1P

AI_1N

Motor PTC

Brake fbk

MltSpd S1

Brake 2 fbk

Emergency mode

MltSpd S0

StartFwdCmd

StartRevCmd

K2M

K3M

Safety

chain

OPTIONAL

OPTIONAL

S1

US1

S2

Figure 5.1: ADL550 connection diagram for brake monitoring

This shows that :

A) The ADL500 controls brake activation/deactivation via relay BR

B) Both brake feedback signals are sent to the ADL500 inputs

C) The ADL500 signals any malfunctions (including brake malfunctions) to the system control unit via internal relay

DRIVE OK.

D) The system control unit blocks the system brake in safety by deactivating contactors K2M and K3M.

According to an alternative arrangement, the ADL500 closes/opens contactors K2M and K3M but the power supply to

the coils and to the ADL500 commands comes from the external, i.e. a control unit.

The purpose of the brake fault alarm is to check whether the states of the two feedback signals from the brake are

consistent and, in case of doubt, to include a function whereby the ADL500 drive stops the system. The procedure for

including the alarm is described below.

A.4

• Activation of the brake fault alarm function.

The installer must have previously located the necessary digital inputs of the ADL500 drive and connected the cor-

responding wires to the feedback signals on these inputs. Note that depending on the type of wiring arrangement, the

brake feedback signals are normally asserted (brake closed – digital input to 1) or normally not asserted (brake closed

– digital input to 0).

Loading...

Loading...