4 - Sprayer setup

38

Hydraulic Systems

General Info

Ensure that the snap couplers are clean before connection!

After having operated the boom and the system has been filled with oil, check the tractor’s hydraulic oil level and top up, if

necessary.

€

DANGER! Test of the hydraulic system should be done very cautiously. There may be air trapped in the system which

can cause violent movements of the boom.

€

DANGER! Hydraulic leaks: Never use your fingers to locate a leakage in any part of the hydraulic system. Due to high

pressure, hydraulic oil may penetrate the skin.

Connecting the hydraulics

Make sure the hydraulic quick couplings are clean and dry taking care to connect the correct hoses to “Pressure” and “Tank”

(the hoses are clearly marked for positive identification). The size and number of hydraulic hoses to connect depends on the

optional equipment fitted to the sprayer. To assist in

identifying the right hoses they have been tagged with colour coded “Zip-

ties.

Requirements for tractor

Y-model requirements (Only on EAGLE Boom)

• One single acting outlet for the lift function of the spray boom.

• One double acting outlet for the folding function.

Z-model requirements

• One double acting outlet for the electro hydraulic operation of the boom functions.

Optional hydraulic system requirements:

• One double-acting outlet for the operation of the FlexCapacity pump (optional).

• One double-acting outlet for the Banjo filling pump

μ

ATTENTION! The hydraulic hoses are marked with arrows to indicate the direction of oil flow.

• The system has a built-in flow regulator that maintains constant speed on hydraulic movements.

• Oil flow between 10 and 90 l/min and a min. pressure of 190 bar.

• Maximum permissible oil pressure is 210 bar.

• Return flow restriction of the connected tractor must be maximum 15 bar.

μ

For Load Sensing systems an oil flow of approximately 3 l/min at 25 bar supplied by the sprayer hydraulics.

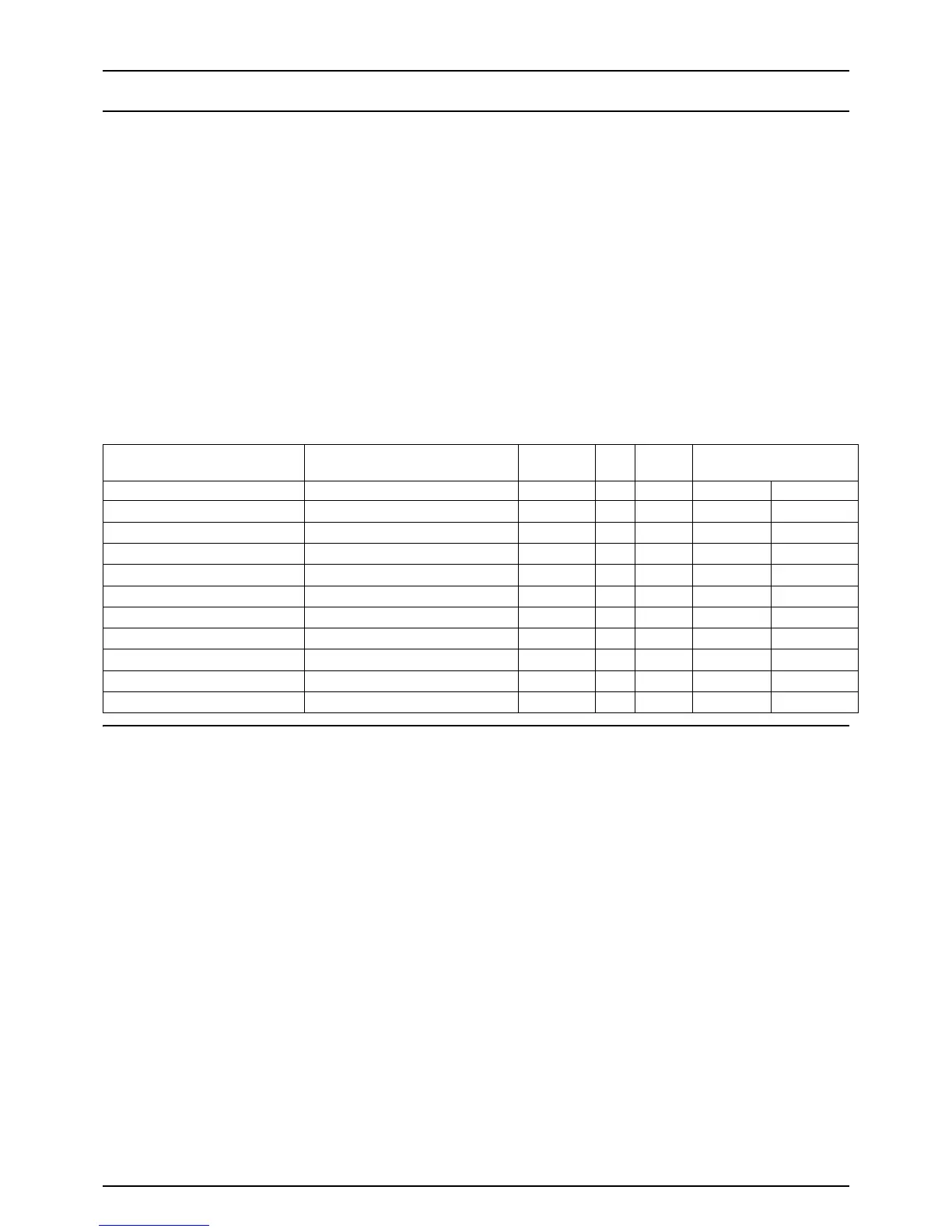

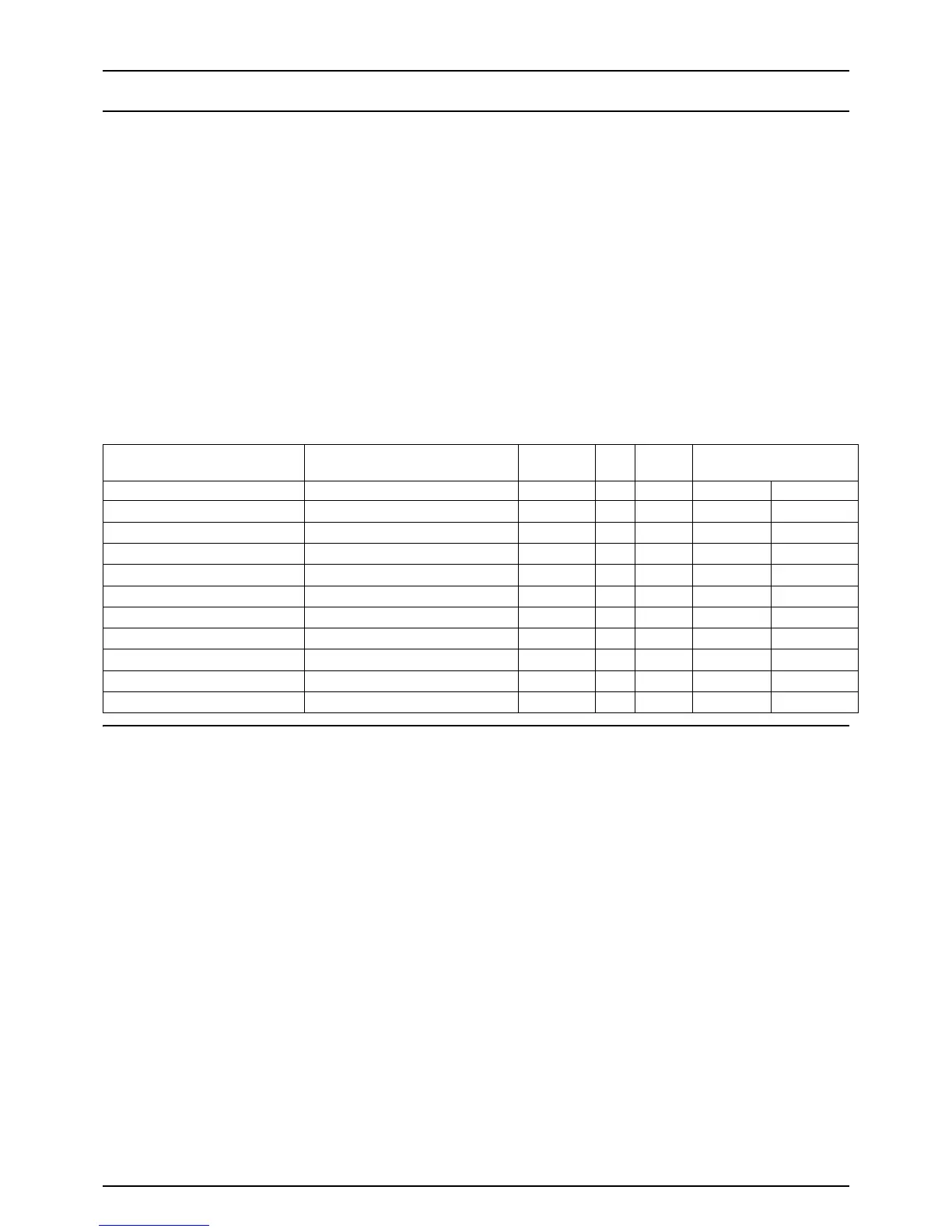

Function Activation Operation

Hose

size

Tag

colour

Hook up

Boom Hydraulics AB

SPC Direct Hydraulics Tractor Remote Control Lift/Lower 3/8” Green Lift /Lower Lift /Lower

SPC Direct Hydraulics Tractor Remote Control Fold 1/4” Yellow Fold-Unfold Fold-Unfold

SPC Electric over Hydraulics Switch Box Control All 3/4” Green Pressure Tank (Return)

FTZ Switch Box Control All 3/4” Green Pressure Tank (Return)

TR4 Switch Box Control All 3/4” Green Pressure Tank (Return)

B3 Switch Box Control All 3/4” Green Pressure Tank (Return)

Options

463/464 Pump Hydraulic Drive Tractor Remote Control Pump drive 1/2” Red Pressure Tank (Return)

Banjo Filling Pump Tractor Remote Control Pump drive 1/2” White Pressure Tank (Return)

Loading...

Loading...