6 - Maintenance

81

10 Hours Service - Spraying Circuit

Fill with clean water and operate all functions. Check for leaks using a higher spray pressure than normal. Check nozzle spray

patterns visually using clean water.

10 Hours Service - Brakes (optional)

Apply brake pedal and check function of trailer brakes.

50 Hours Service - Transmission Shaft

Check function and condition of the transmission shaft protection guard. Replace any damaged parts.

50 Hours Service - Wheel Nuts

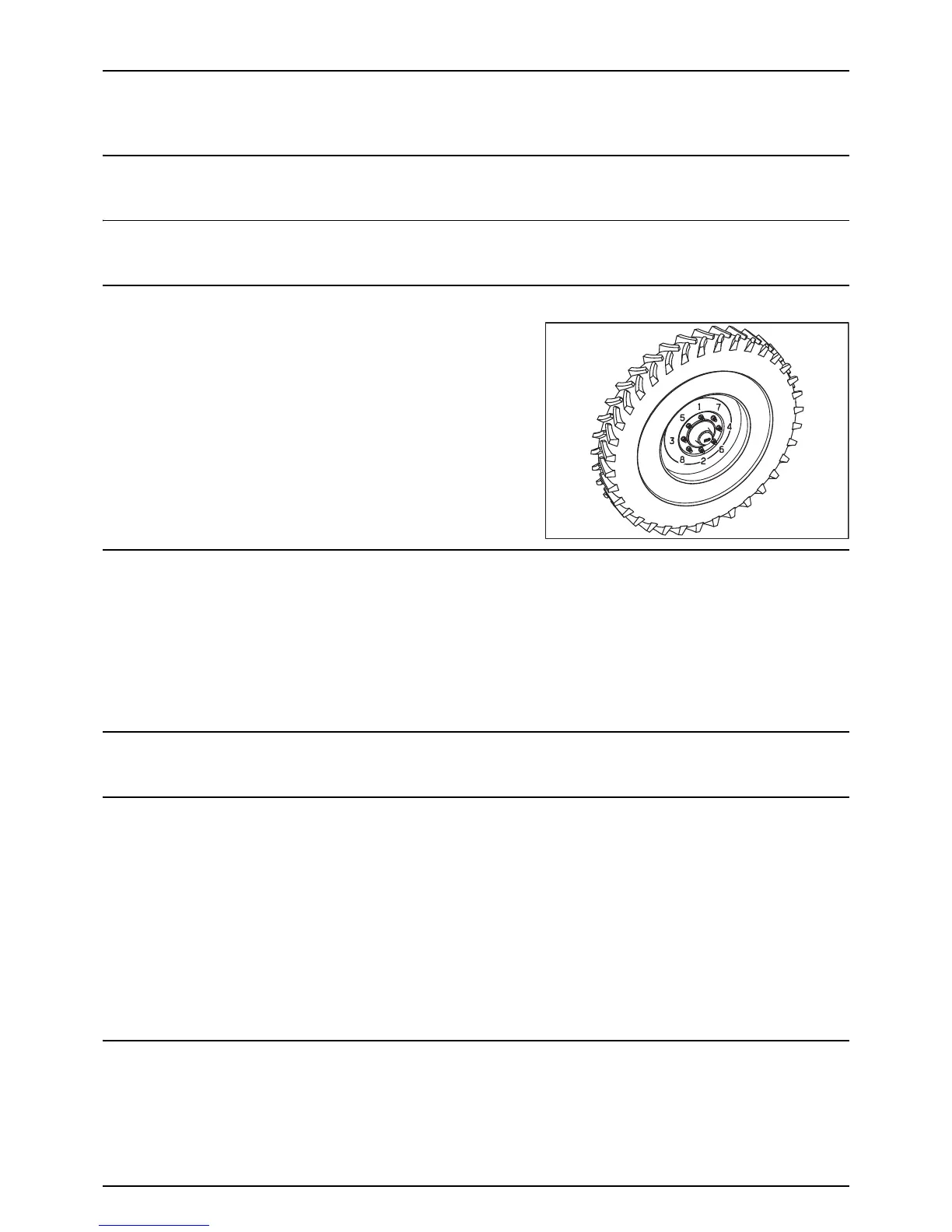

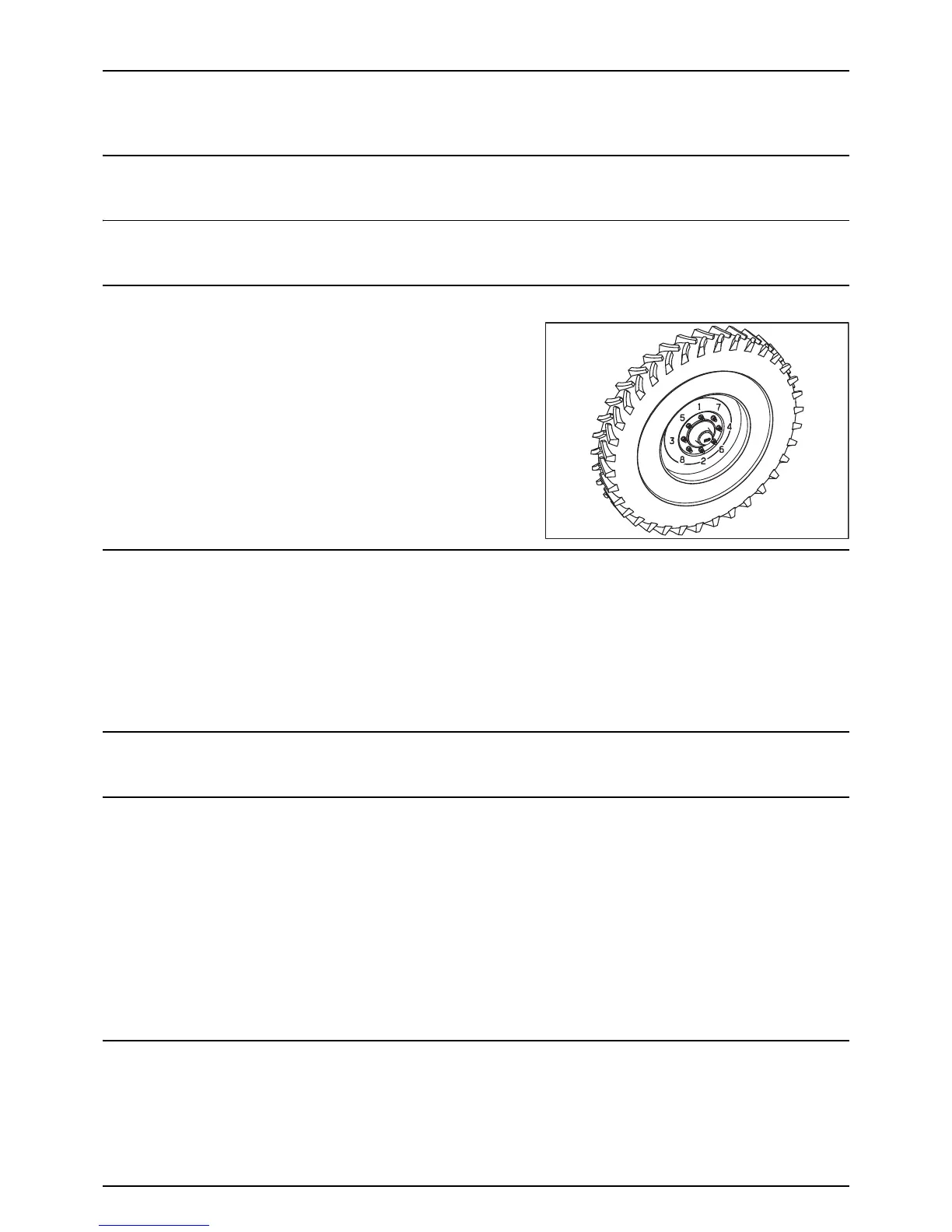

Tighten wheel nuts as follows.

Torque wrench setting for mounting wheel hub to rim plate: 490 Nm.

Tightening sequence for wheel nuts: See illustration and tighten in the

numbered order.

μ

ATTENTION! When wheels has been mounted or re-tightened,

the plastic nut covers must be placed on the nuts afterwards.

50 Hours Service - Tyre Pressure

Check the tyre pressure according to the table in “Technical Specifications”.

€

DANGER! Never inflate tyres more than to the pressure specified in the table. Over-inflated tyres can explode and

cause severe injuries! See the section “Occasional Maintenance - Change of Tyres”.

±

WARNING! If renewing tyres, always use tyres with minimum load index as specified.

250 Hours Service - Readjustment of the Boom

Please refer to Boom Manual

250 Hours Service - Hydraulic Circuit

Check the hydraulic circuit for leaks and repair, if needed.

Refill nitrogen accumulators for:

• ParaLift

• Suspension (if fitted)

±

WARNING! Hoses for boom lifting device must be changed after every 5 years of use.

±

WARNING! Nitrogen accumulators may contain oil under pressure.

250 Hours Service - Hoses and Tubes

Check all hoses and tubes for possible damage and proper attachment. Replace damaged hoses or tubes.

Loading...

Loading...