Loading...

Loading...

Do you have a question about the Honda BF15D and is the answer not in the manual?

| Displacement | 350 cc (21.4 cubic inches) |

|---|---|

| HP Rating | 15 HP |

| Fuel Delivery | 1 Carburetor |

| Ignition System | Digital CDI |

| Cooling System | Water Cooled |

| Gear Ratio | 2.08:1 |

| Lubrication | Wet Sump |

| Gear Shift | F-N-R |

| Engine Type | 4-stroke |

| Full Throttle RPM Range | 5000 - 6000 rpm |

| Starting System | Manual |

| Exhaust | Through Propeller |

| Fuel Tank Capacity | External tank |

| Oil Capacity | 1.1 L |

| Fuel | Unleaded Gasoline |

| Shaft Length | 15 inches |

Information about safety messages and signal words like DANGER, WARNING, CAUTION.

Details on various models' dimensions and weights.

Covers engine specifications like displacement, horsepower, fuel, cooling, lubrication, etc.

Details about clutch, gear ratio, propeller specifications, and rotating direction.

Explains common symbols used throughout the manual.

Shows locations for frame and engine serial numbers for reference.

Lists standard maintenance specifications and service limits for various parts.

Specifies torque values for various fasteners.

Lists essential tools required for specific procedures.

Provides guidance for diagnosing and resolving common operational issues.

Outlines the maintenance schedule and procedures for engine oil checks and changes.

Covers maintenance for oil filter, gear case oil, spark plugs, fuel filter, and fuel system components.

Covers valve clearance, carburetor, throttle linkage, timing belt, and crankcase breather maintenance.

Procedures for removing, installing, and assembling the gear case.

Procedures for servicing the propeller shaft holder, including bearing and seal replacement.

Procedures for disassembling, inspecting, and assembling the water pump.

Procedures for servicing the vertical shaft, bevel gears, and related bearings and shims.

Procedures for removing and reinstalling the main engine cover.

Procedures for removing and installing the left engine under cover.

Procedures for removing and installing the right engine under cover.

Covers service for the carburetor, silencer, and related components.

Covers maintenance of the fuel pump, fuel filter, fuel tubes, and fuel tank.

Procedures for removing, inspecting, and reassembling the choke cable.

Procedures for removing, installing, and adjusting the neutral start cable.

Covers removal, disassembly, inspection, assembly, and installation of the recoil starter.

Procedures for removing and installing the starter case B.

Detailed steps for removing the engine from the outboard motor.

Detailed steps for installing the engine onto the outboard motor.

Procedures for removing, inspecting, and installing the flywheel and coils.

Procedures for removing, inspecting, and installing the timing belt and pulleys.

Covers cylinder head removal, disassembly, assembly, installation, and valve/seat/guide service.

Covers disassembly, inspection, assembly, and installation of the oil pump.

Covers removal, disassembly, assembly, and installation of pistons and rings.

Covers disassembly, inspection, assembly, and installation of the crankshaft and cylinder block.

Covers service for the oil case, mount frame, and friction adjusting lever.

Procedures for removing and installing the stern bracket for different tilt types.

Procedures for disassembling and reassembling the swivel case and its components.

Covers service for power tilt and gas assisted tilt assemblies.

Procedures for removing and installing the shift/throttle arm assembly for remote control type.

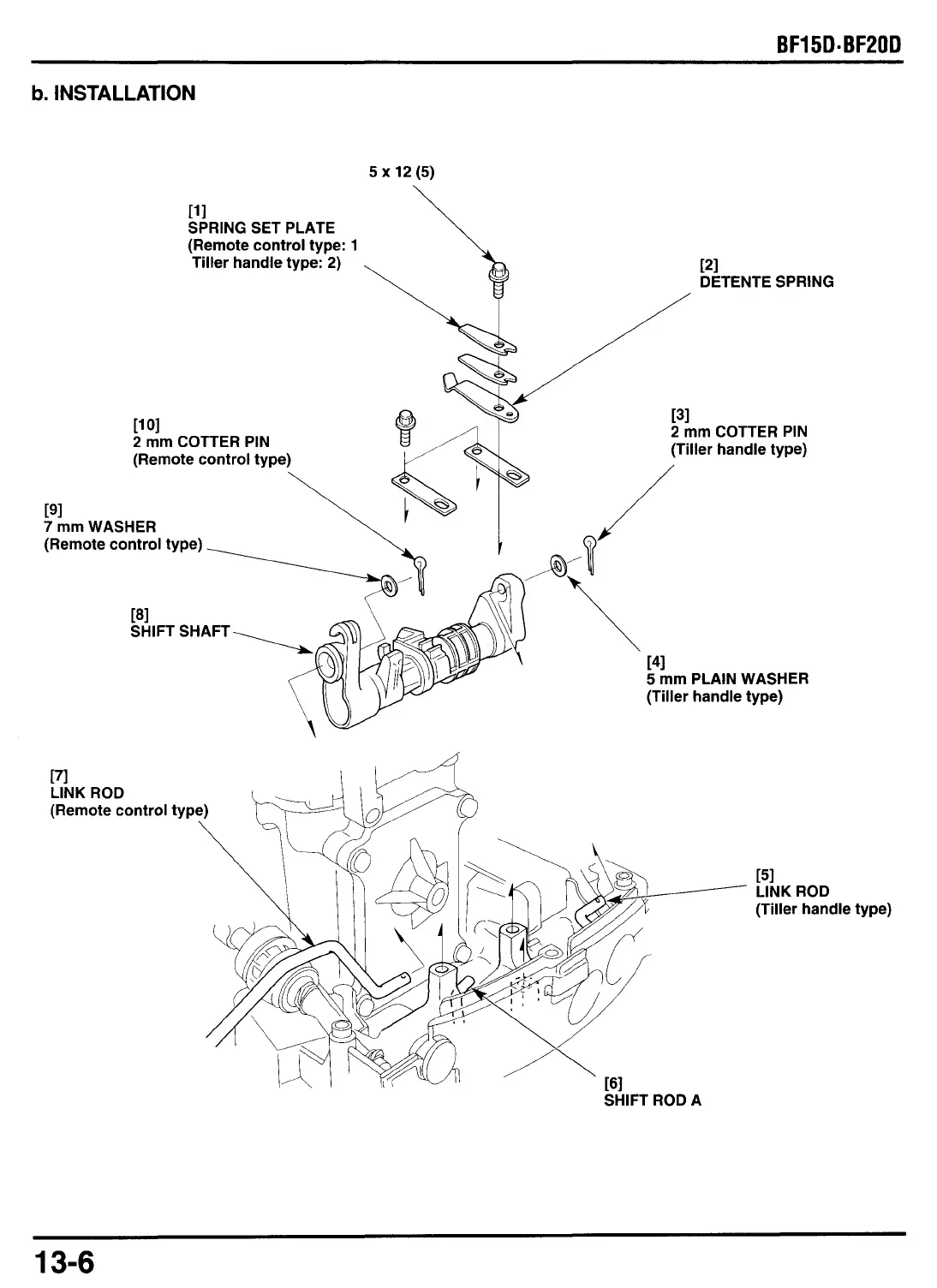

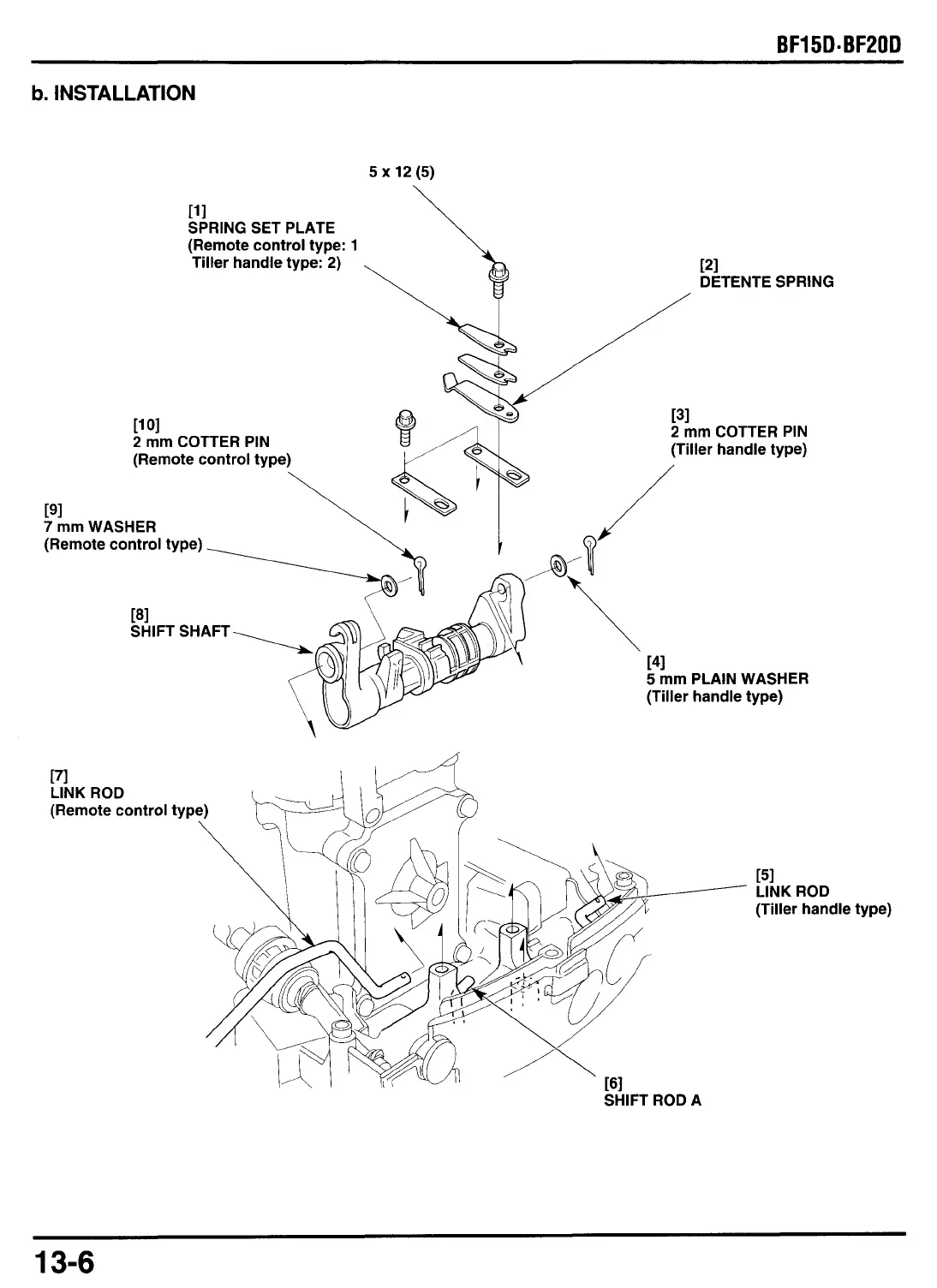

Covers removal and installation of the shift lever and shift shaft.

Covers removal/installation of the steering rod and remote control cables.

Covers service for the remote control box and its wire harness.

Covers removal, inspection, and replacement of the power tilt switch.

Covers removal and installation of the tiller handle bracket and throttle grip.

Covers inspection and replacement of the starter and emergency stop switches.

Procedures for removing, disassembling, inspecting, assembling, and installing the starter motor and cable.

Covers service for the ignition control module and ignition coil.

Covers service for charge wire, neutral switch, and regulator/rectifier.