MAINTENANCE

Inspect

and

adjust

the decompressor

CleBrBnCe

while

fhe

engine

is

cold

(be/ow 35"C/95'f).

4-18

DECOMPRESSOR CLEARANCE

INSPECTIONI

ADJUSTMENT

('05 - '07)

Always

inspect and adjust

the

decompressor

clear-

ance after adjusting the r

ight

exhaust valve clear-

ance.

Remove the

following:

- Cylinder head cover (page 9-7)

- Crankshaft hole cap (page 9-8)

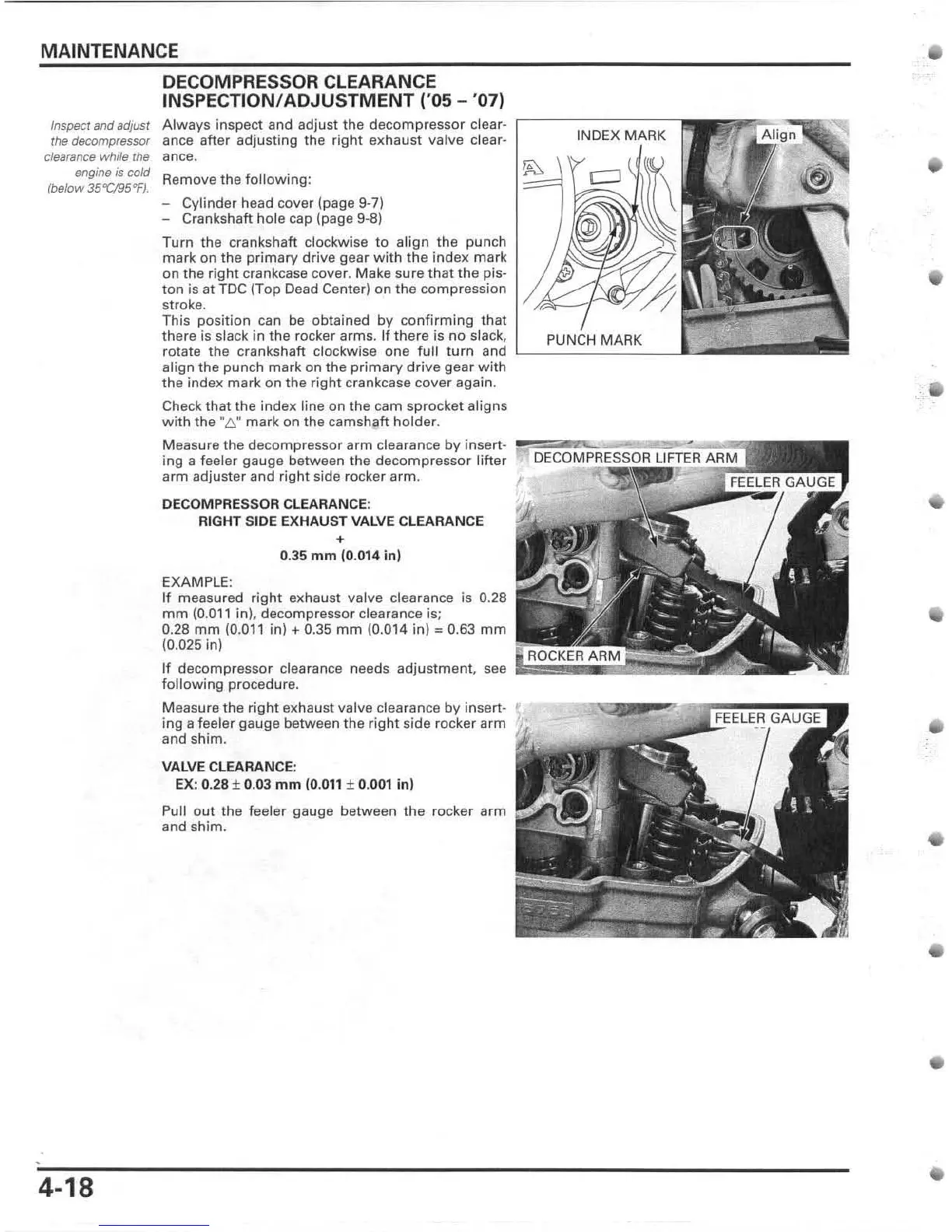

Turn the crankshaft

clockwise to al

ign

the punch

mark on the

primary

drive

gear

wi

th the index

mark

on the right crankcase cover. Make sure

that

the pis-

ton is at

TDC

(T

op

Dead Center)

on

the

compression

stroke.

This

position

can

be

obtained

by

confirming

that

there is slack in the rocker arms. If there is

no

slack,

rolate the crankshaft clockwise

one

full

turn and

align

the punch

mark

on

the

primary

drive

gear

wi

th

the

index

mark

on

the right crankcase cover again.

Check that the index line

on

the cam s

pr

ocket aligns

with

the "6."

mark

on the

camsh~ft

holder.

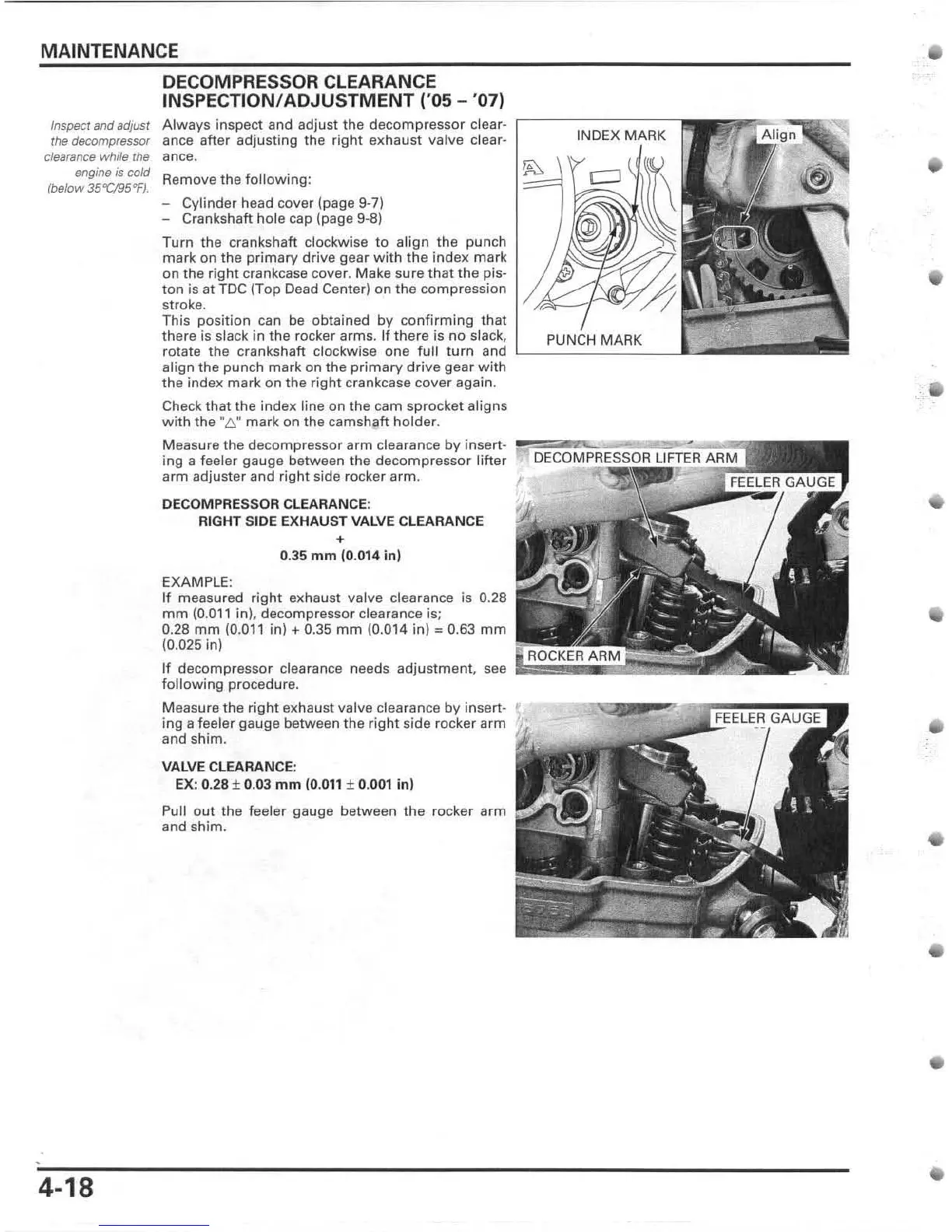

Meas

ur

e the decompressor

arm

clearance

by

insert-

ing a feeler gauge between the

decompressor

lifter

arm adjuster

and

right side rocker

arm

.

DECQMPRESSQR CLEARANCE:

RIGHT SIDE EXHAUST

VALVE CLEARANCE

+

0.35

mm

(0.014 in)

EXAMPLE:

If measured rig

ht

exhaust valve clearance is 0.28

mm

(0.0

11

in

),

decompressor clearance i

s;

0.28

mm

(0.011 in)

...

0.35

mm

(0.014 in) '" 0.63

mm

(0.025 in)

If

decompressor

clearance needs

adjustment,

see

following

procedure.

Measure the rig

ht

exhaust valve clearance

by

insert-

ing

a feeler gauge between the r

ight

si

de

rocker

arm

and shim.

VALVE

CLEARANCE:

EX

: 0.

28

± 0.

03

mm

(0.

011

± 0.

001

in)

Pull

out

the feeler gauge between the rocker a

rm

and shim.

INDEX MARK

•

•

•

Loading...

Loading...