Preventive maintenance

11 2 811390 Operator Manual DynaMAX 550P/560P/575P Waterjet Pump

Install the high-pressure hoops, the high-pressure water seals, the high-pressure cylinders, and the

check valves

Parts, tools, and materials

1. Put the seal installation spacer tool on a clean, dry surface.

Do not put grease or lubricant on the check valve face or in the cylinder bore. These

components are designed for dry contact.

Repair the high-pressure cylinders and the check valves every 500 hours.

Repair the high-pressure hoops and the high-pressure water seals every 500 hours.

Replace the check valves every 2,000 hours.

Replace the high-pressure cylinders:

• every 3,000 hours

• if the cylinder is chipped or cracked

Install a new plunger bearing when replacing the high-pressure cylinder.

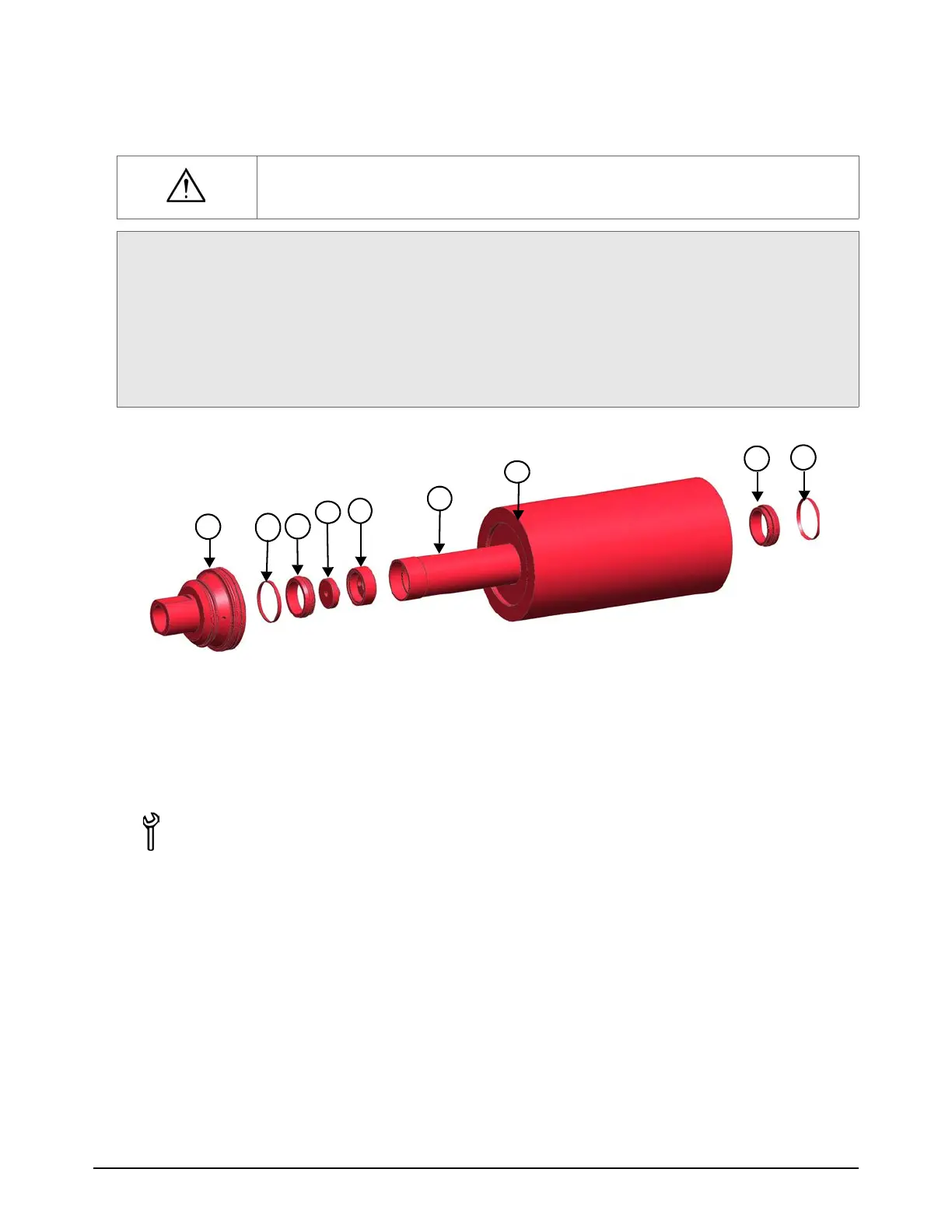

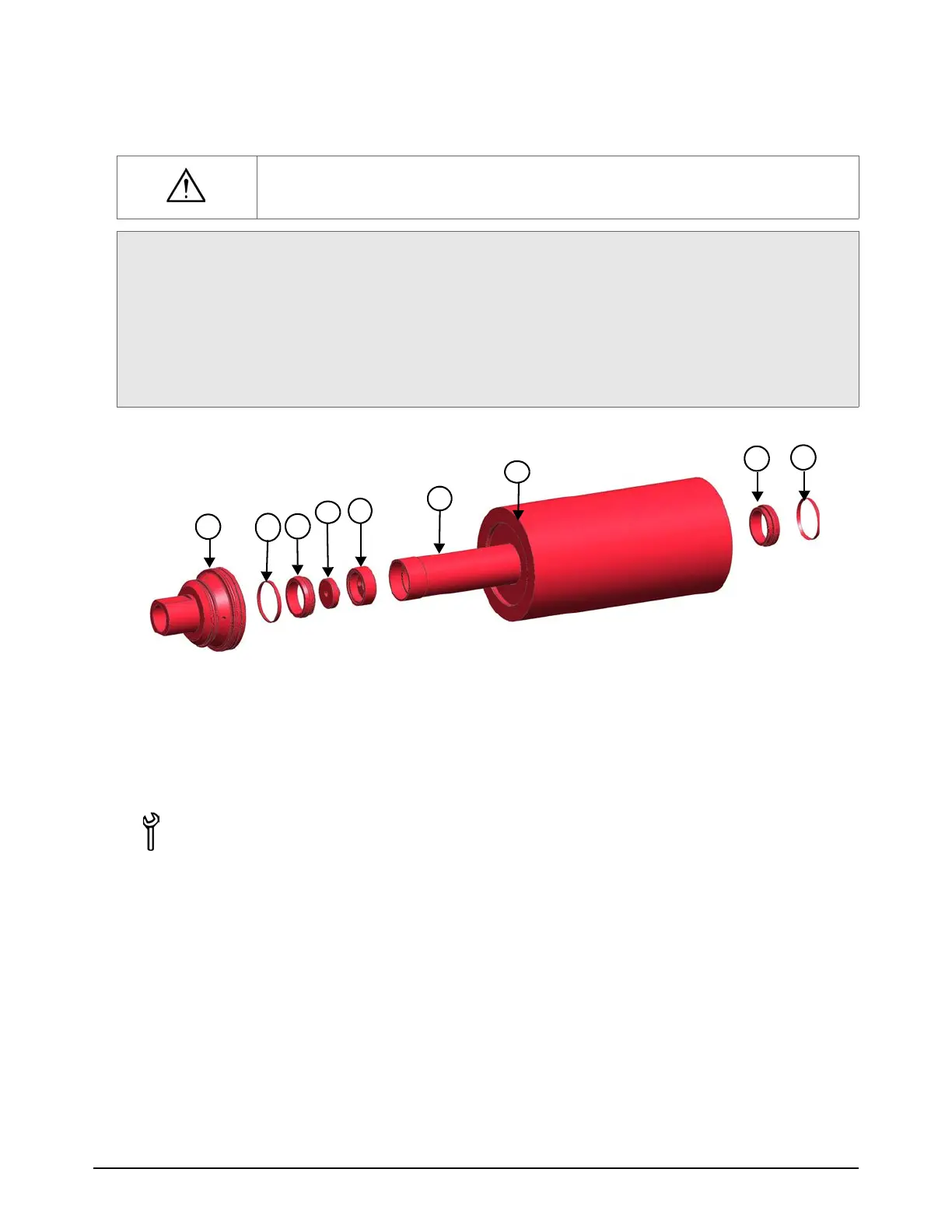

1 Check valve assembly

2 High-pressure hoop

3 High-pressure water seal

4 Low-pressure poppet

5 Low-pressure poppet basket

6 Spacer tube

7 High-pressure cylinder

DynaMAX premium high-pressure seal repair kit.

DynaMAX poppet repair kit

Check valve assembly

Low-pressure poppet basket

Spacer tube

High-pressure cylinder

High-pressure antiseize lubricant such as

Blue Goop or PURE Goop

Seal installation tools (Refer to 1-12084

DynaMAX 5-series standard Tool kit).

Rubber mallet

Loading...

Loading...