Preventive maintenance

DynaMAX 550P/560P/575P Waterjet Pump Operator Manual 811390 11 7

Parts, tools, and materials

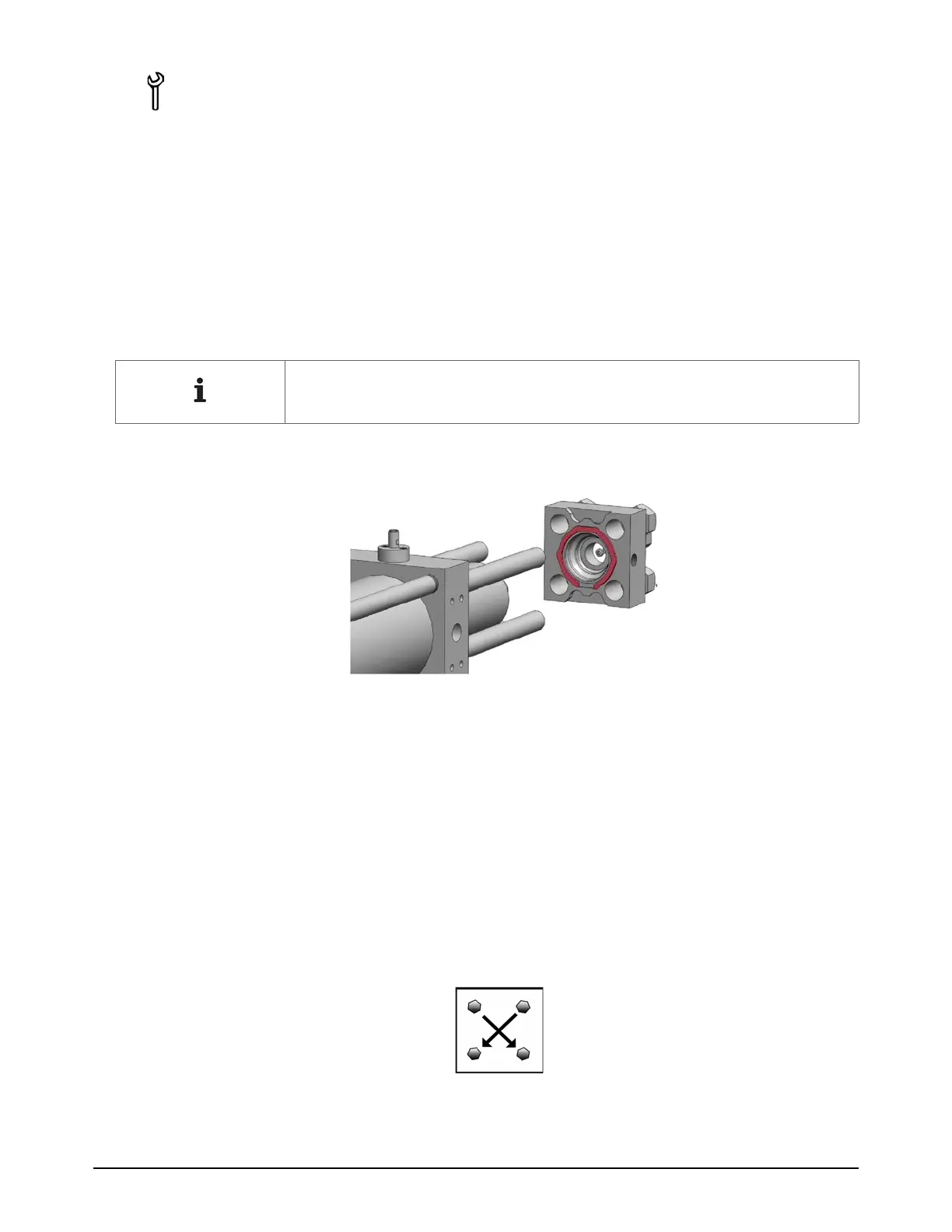

1. Put O-ring lubricant on the check valve O-ring. Put the O-ring on the check valve.

2. Install the gasket in the groove in the high-pressure end cap. The cutout in the gasket directs

fluid down into the drip tray.

3. Put the high-pressure end cap onto the check valve and the studs with the water fitting pointed

toward the attenuator.

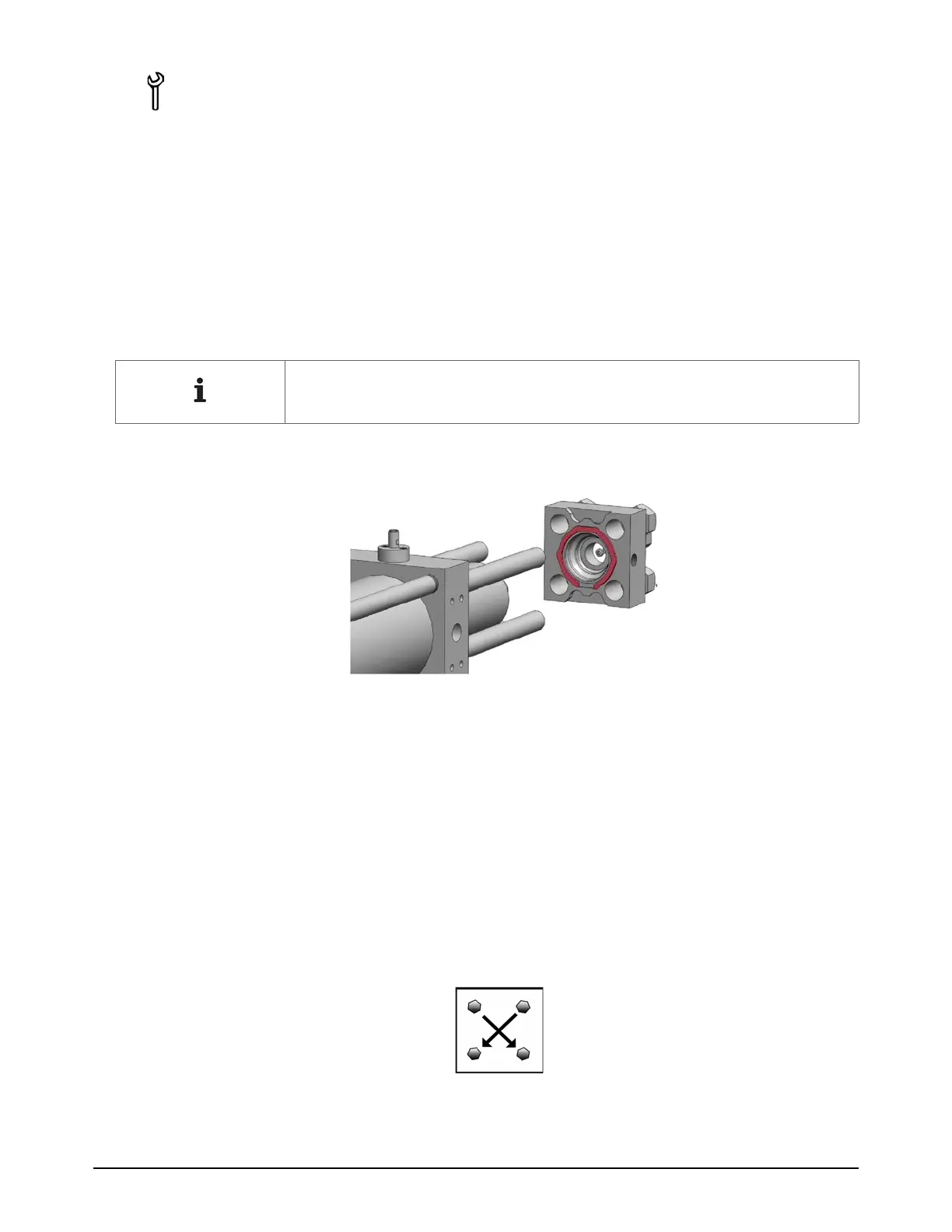

4. Put antiseize bolt lubricant on the stud threads.

5. Tighten the nuts on the studs by hand.

6. Put the smooth side of the nut toward the high-pressure end cap.

7. Torque the end cap nuts to 375 N∙m (275 lbf∙ft). Refer to High-pressure end cap nut on

page 180

8. Tighten each fastener in 68 N∙m (50 lbf∙ft) increments. Use a repeating cross pattern. Refer to

Special fasteners on page 180

9. Connect the low-pressure water line.

Antiseize bolt lubricant (white lithium grease)

High-pressure antiseize lubricant such as

Blue Goop or PURE Goop

Torque wrench, 3/4-inch drive,80 N∙m to400

N∙m(60 lbf∙ft to300 lbf∙ft)

(included in the 1-12084 DynaMAX 5-series

standard Tool kit).

Square drive socket, 1-1/2 inch × 3/4 inch

(included in the 1-12084 DynaMAX 5-series

standard Tool kit).

Petroleum-based O-ring lubricant

The O-rings are installed on the larger outer diameter of the check valve to seal on

the inner diameter of the high-pressure end cap.

Loading...

Loading...