2 Installation and Wiring

-

62

-

Cable connection

1) Cable selection for control circuit

■

Use copper conductors of a proper size as control cables according to the

recommended values in

Table 3-2

.

2) Cabling requirement of control circuit

■

The motor cables must be laid far away from all control cables.

■

It is recommended that the motor cables, power input cables and control cables

change of the output voltage of the controller, the motor cables and control cables

must not be laid side by side for a long distance.

■

If the control cable must run across the power cable, make sure they are arranged

at an angle of close to 90° .

■

Figure A-6 shows the recommended cabling diagram.

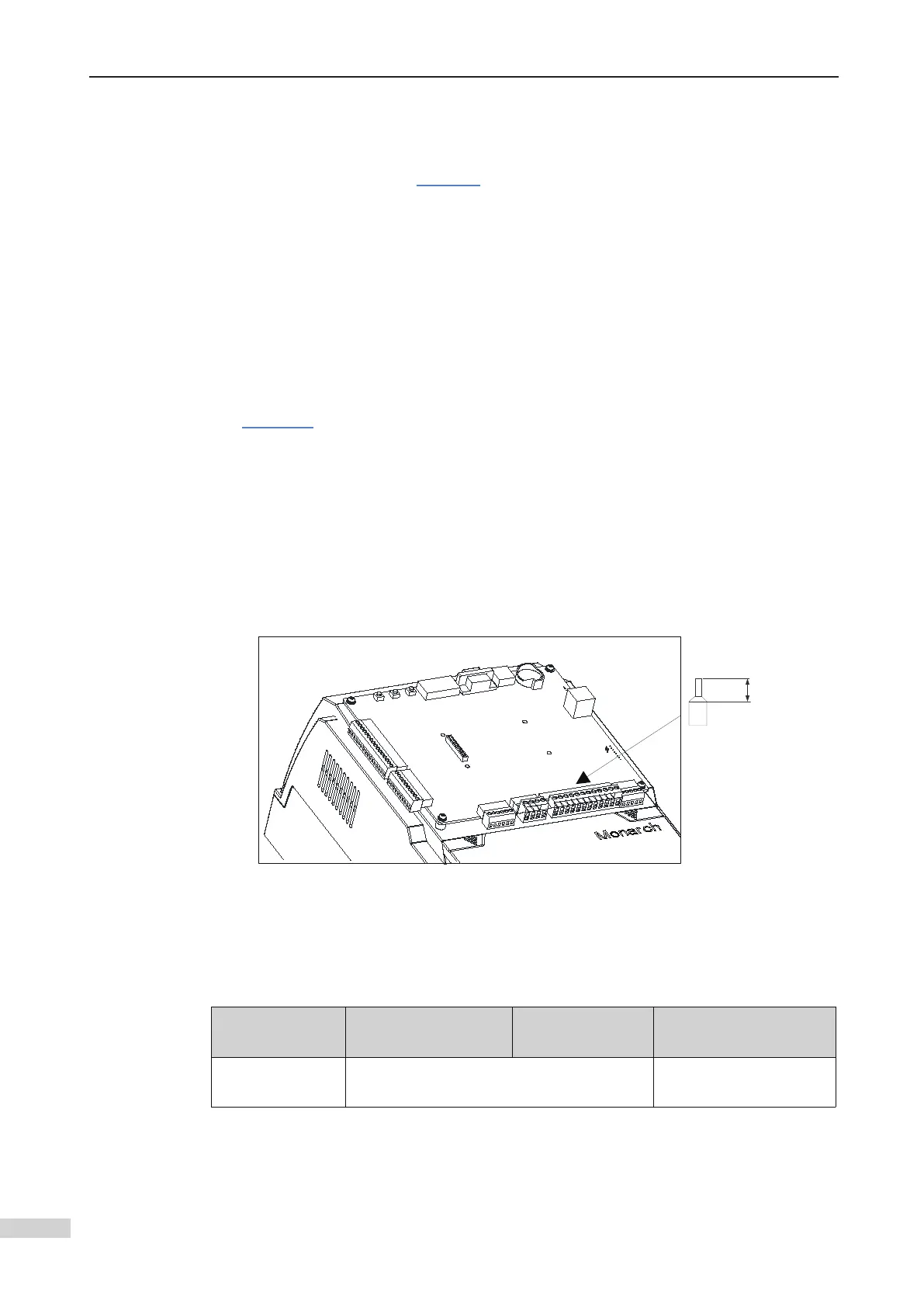

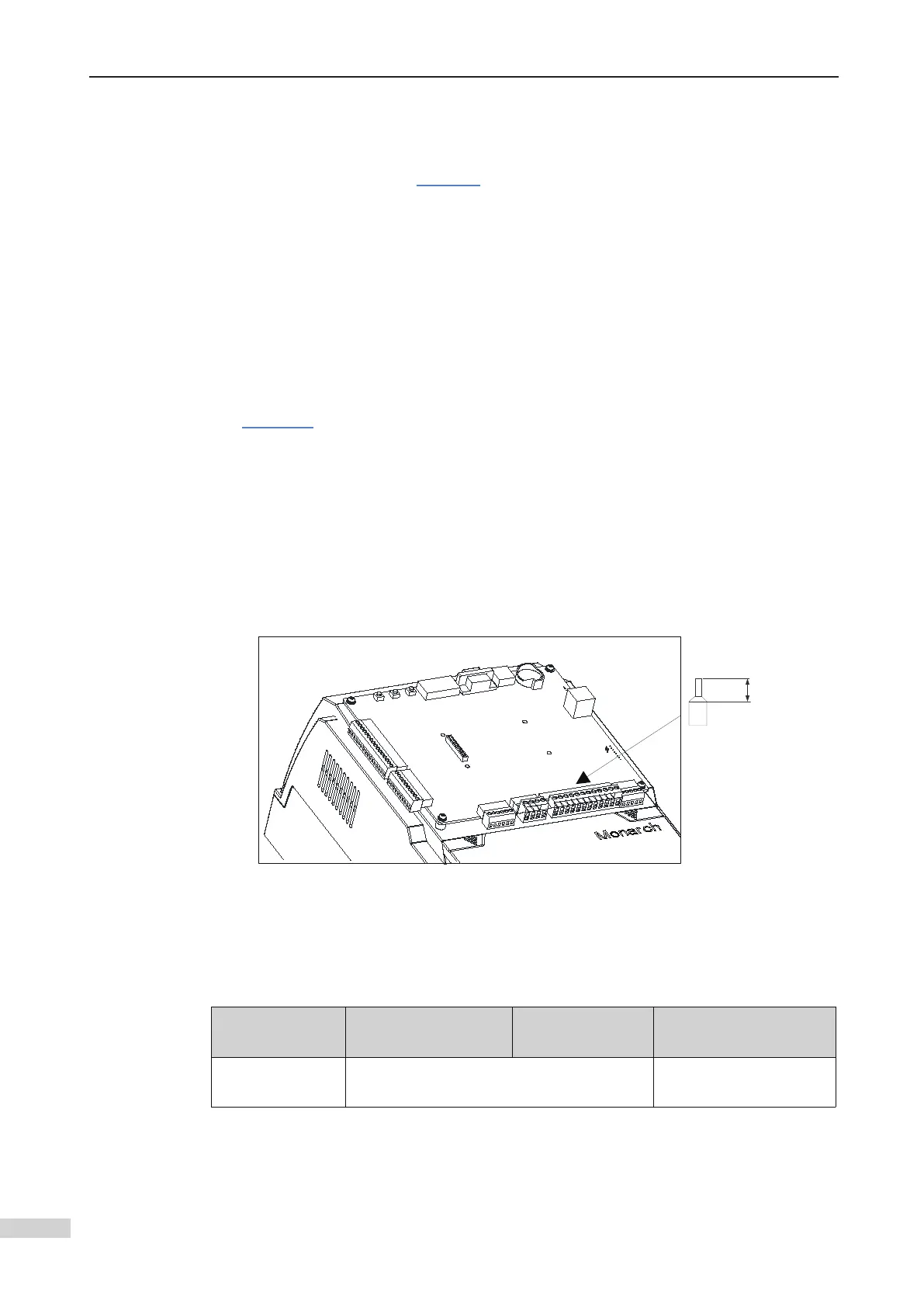

2.2.4 Control Circuit Cable Sizes and Tightening Torque

Tubular terminal:

Use the tubular terminal with the insulation sleeve.

When the single cable or twisted pair is used, the cable end must be exposed by 6 mm.

Control cable tubular terminal requirement

Terminal Name

Single Cable mm²

(AWG)

Twisted Pair mm²

(AWG)

Torque of Torque Driver

(N·m)

Control circuit

terminal block

0.565

Loading...

Loading...